Understanding the Pricing for Flat Surface Polishing Machines

Flat surface polishing machines play a crucial role in various industries, including manufacturing, automotive, and aerospace, where surface finish quality directly impacts product performance and aesthetic appeal. As the demand for precise machining continues to increase, understanding the pricing of these machines becomes essential for businesses looking to invest in their production capabilities. In this article, we will explore the factors influencing the cost of flat surface polishing machines and provide a general overview of price ranges you might encounter.

Factors Influencing Price

1. Type of Machine The primary determinant of the price is the type of polishing machine. There are various types available, including manual, semi-automatic, and fully automatic machines. Manual machines are usually the least expensive, while fully automated systems tend to be the most expensive due to their advanced technology and features.

2. Size and Capacity Larger machines capable of processing bigger workpieces naturally come at a premium. The size of the machine also dictates the complexity of the design and technology involved in its construction, further influencing the price.

3. Material Compatibility Machines designed to polish a wider range of materials (e.g., metals, plastics, glass) typically cost more than those designed for specific materials. Businesses that work with diverse materials may opt for multi-purpose machines, while specialized machines might be less expensive but limited in scope.

4. Brand and Manufacturer Brand reputation significantly impacts pricing. Established brands with proven reliability often charge higher prices. However, they also come with the assurance of quality, customer service, and availability of spare parts.

5. Technological Features Modern flat surface polishing machines integrate various technological advancements, such as digital controls, advanced cooling systems, and user-friendly interfaces. Machines equipped with these features will generally be more expensive than those with basic functionalities.

6. Customization Options Some manufacturers offer customization options that can influence the price. Custom-built machines designed to meet specific user requirements may come at a higher cost, but they can provide a significant return on investment by improving efficiency and output quality.

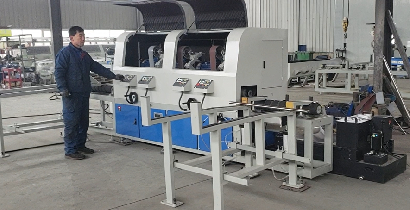

flat surface polishing machine pricelist

7. Market Demand and Location Local market conditions and demand for polishing machines can affect pricing. In regions where there is high industrial activity, prices may be inflated due to increased demand. Additionally, import taxes and tariffs may impact costs for machines sourced from abroad.

Price Ranges

On average, the pricing of flat surface polishing machines falls into several categories

- Entry-Level Machines These are often manual or semi-automatic machines priced between $2,000 and $10,000. They are suitable for small workshops or startups looking to handle essential polishing tasks without significant investment.

- Mid-Range Machines Priced between $10,000 and $50,000, these machines often feature semi-automatic operations and improved technology. They cater to businesses requiring better precision and efficiency in their operations.

- High-End Machines Fully automatic systems can range from $50,000 to well over $200,000. These machines come equipped with top-of-the-line technology and are capable of high-volume production with minimal human intervention. They are ideal for large manufacturing facilities where the quality of polish and throughput are paramount.

Conclusion

Investing in a flat surface polishing machine is a significant decision that can influence the quality of your products and the efficiency of your operations. Understanding the various factors that determine pricing helps businesses make informed decisions based on their specific needs and budgets. It is advisable to conduct thorough market research, consider the long-term benefits of more advanced machines, and consult with manufacturers or industry experts to find the best fit for your operations. As you explore the possibilities, remember that the initial investment can lead to significant improvements in both product quality and overall productivity, offering a solid return on your investment in the long run.