Exploring the Importance of Flat Surface Polishing Machines and Their Manufacturers

In the world of manufacturing, achieving a high-quality finish on flat surfaces is crucial across various industries, including automotive, aerospace, electronics, and furniture production. Flat surface polishing machines are essential tools in this process, designed to enhance the smoothness and overall appearance of materials such as metal, glass, wood, and plastic. Understanding the significance of these machines and the role of manufacturers helps businesses make informed decisions about their production processes.

Flat surface polishing involves removing imperfections, scratches, and abrasive marks from the surface of materials. This finish not only improves aesthetic appeal but also prepares surfaces for subsequent processes, such as coating or painting. The demand for flat surface polishing machines has grown exponentially due to the increasing focus on quality and precision in manufacturing. A well-polished surface ensures better adhesion for paints and coatings, enhances durability, and often improves product performance.

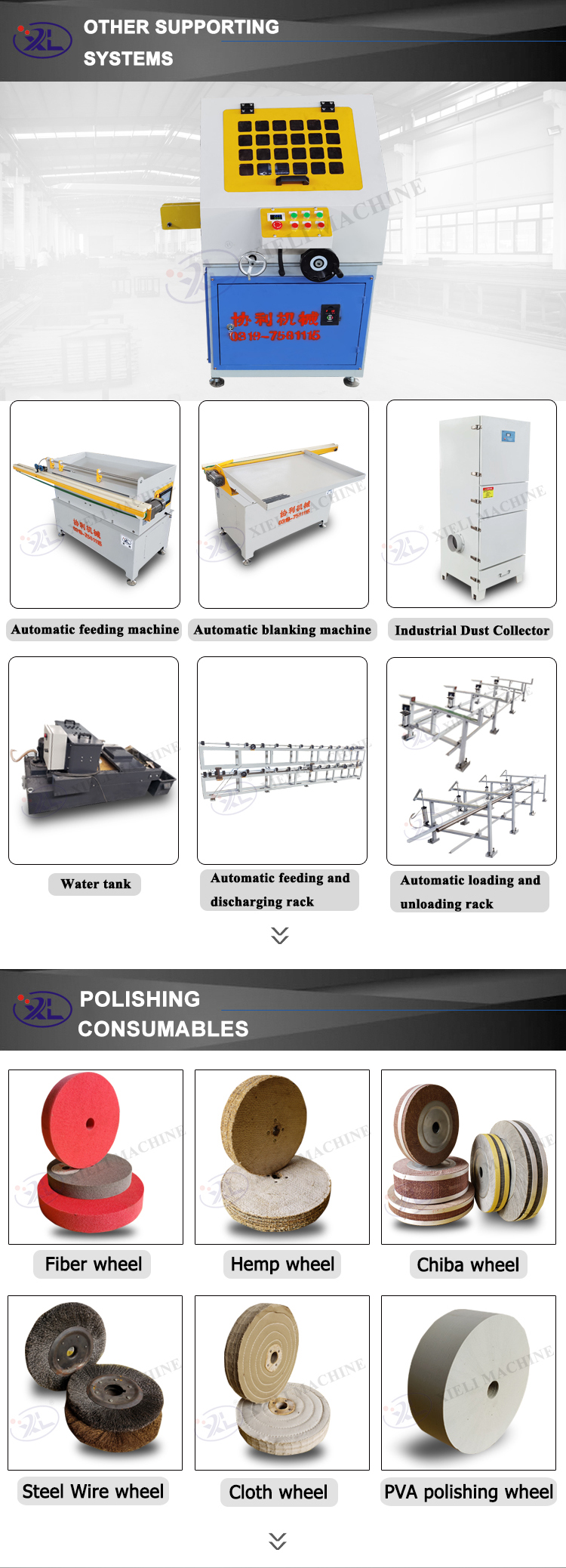

Manufacturers of flat surface polishing machines play a pivotal role in meeting industry needs. These companies invest in research and development to innovate and improve their products continually. They offer a range of machines, from simple, manual models to advanced, fully automated systems. The choice of machine often depends on the specific requirements of the production line, including the type of material being polished, the desired finish quality, and production volume.

flat surface polishing machine manufacturers

Top manufacturers in the field emphasize precision engineering and robust construction. They often collaborate with industry experts to understand the evolving trends and challenges in surface finishing. Additionally, many manufacturers focus on providing customizable solutions to cater to the unique needs of their clients. This flexibility allows businesses to scale their operations effectively while maintaining high standards of quality and finish.

Moreover, leading manufacturers also prioritize sustainability and energy efficiency in the design of their machines. With the growing emphasis on environmentally friendly practices, many companies are integrating features that reduce waste and energy consumption during the polishing process. This not only benefits the environment but can also lead to cost savings for manufacturers in the long run.

When selecting a flat surface polishing machine, it’s essential for businesses to consider factors such as machine reliability, ease of operation, and after-sales support from the manufacturer. A good partnership with a reputable manufacturer can significantly impact production efficiency and product quality.

In conclusion, flat surface polishing machines are indispensable in achieving top-notch finishes in various industries. With the ongoing advancements in technology and manufacturing practices, businesses should collaborate closely with reliable manufacturers to ensure optimal performance and quality in their production processes. Investing in high-quality polishing machines is crucial for maintaining a competitive edge in today’s market.