Flat polishing machines have revolutionized the way industries achieve precise surface finishes on a wide variety of materials. In the competitive world of manufacturing, achieving impeccable surface quality is critical, not only for aesthetic purposes but also for functional performance. Flat polishing machines stand as the cornerstone technology, particularly in sectors such as automotive, electronics, and aerospace, where precision engineering is paramount.

Experience in using flat polishing machines reveals that versatility is one of their most significant assets. Unlike traditional polishing methods that might be limited by material type, flat polishing machines can handle metals, ceramics, and polymers with equal efficiency. This adaptability is invaluable across various industries where manufacturers require a consistent finish on diverse components. In practice, this means that a single machine model is capable of addressing the polishing needs of different production lines, thereby increasing operational efficiency and reducing costs.

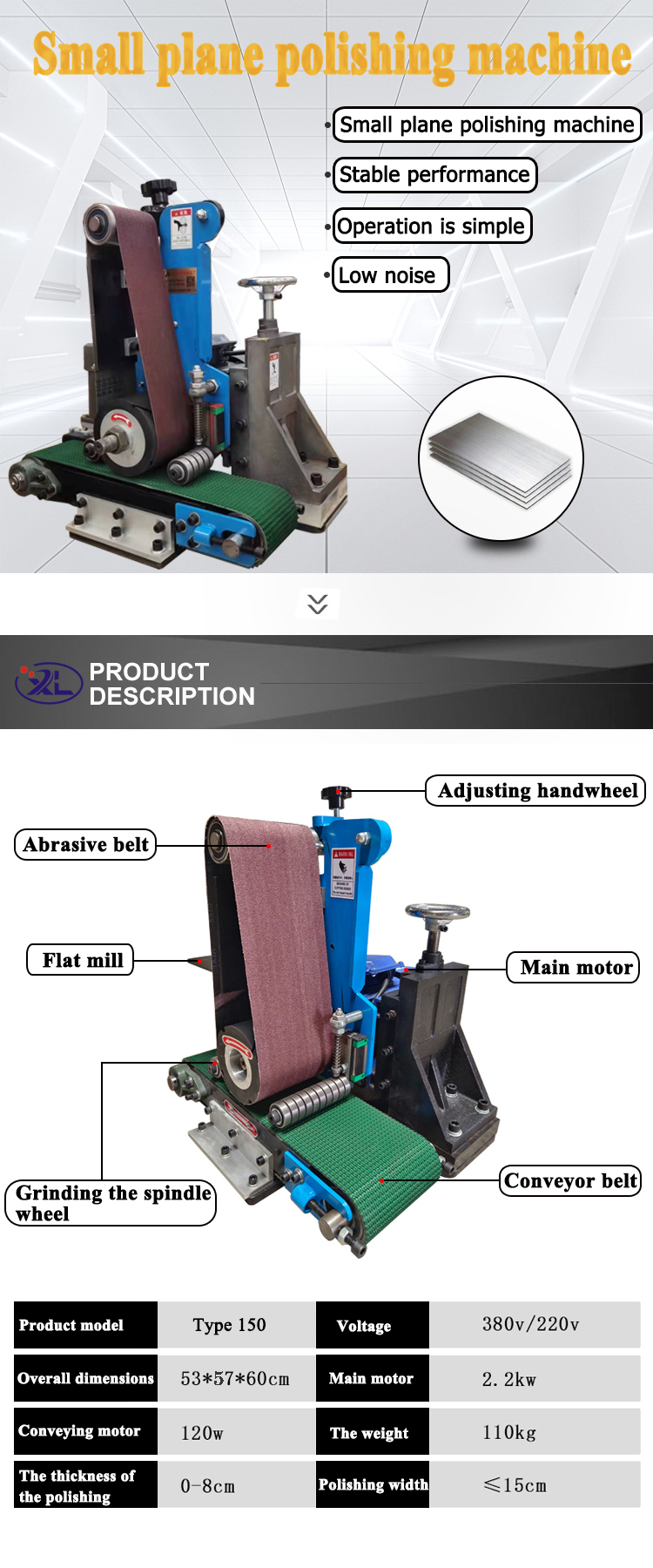

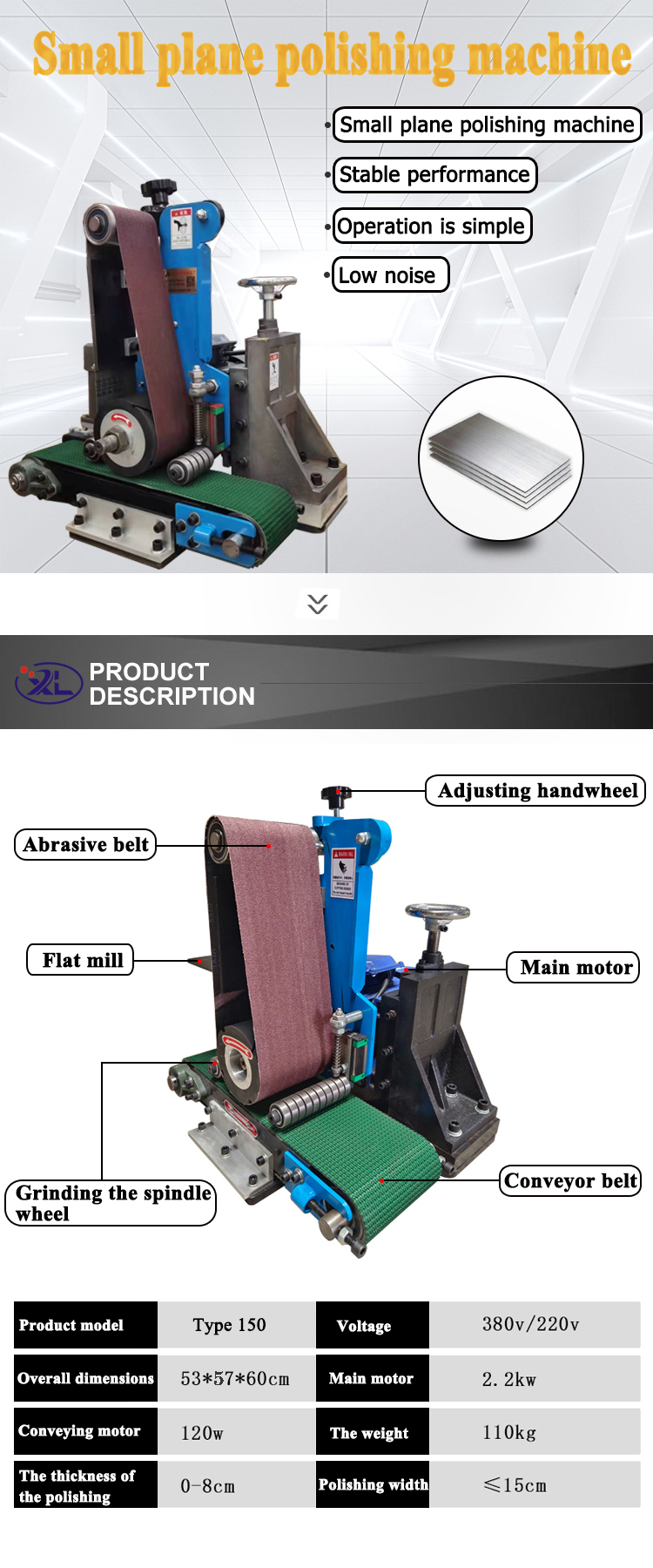

From an expertise perspective, understanding the nuances of operating a flat polishing machine is essential. The key lies in mastering parameters such as speed, pressure, and the type of polishing compound used. For instance, optimizing these variables can significantly impact the smoothness, gloss, and even the durability of the final product. Experts recommend regular calibration and alignment checks to ensure that the machine runs at peak performance, which in turn maintains product consistency. For newcomers, investing time in hands-on training sessions and learning from seasoned operators can demystify the complexities involved in achieving professional-grade finishes.

The authoritativeness of flat polishing machines is backed by their widespread adoption and endorsement by industry leaders. These machines are trusted not only for their superior finish quality but also for their reliability under high-demand conditions. Industry standards and certifications further testify to their capability. For example, adherence to ISO surface finish standards is often a prerequisite in sectors like aerospace; flat polishing machines are designed with these rigorous requirements in mind, ensuring compliance and avoiding costly re-works or project delays.

flat polishing machine

Trustworthiness in the context of flat polishing machines is reflected in their durability and product support offered by manufacturers. These machines are engineered with robust materials capable of withstanding the wear and tear associated with continuous high-paced industrial use. Leading manufacturers provide extended warranties and comprehensive after-sales support, including maintenance services and user training programs. This level of support is crucial, particularly for companies operating 24/7 production cycles, where machine downtime could lead to significant financial losses.

Industry insights suggest that technological advancements continue to enhance the capabilities of flat polishing machines.

Integration with smart technologies is now a common trend. Advanced systems can monitor operational metrics in real time, alerting operators to potential issues before they escalate. Additionally, eco-friendly polishing compounds have seen increased use, reflecting the industry's shift towards sustainable practices. Implementing these innovations can lead to reduced environmental impact and align with broader corporate social responsibility goals.

In conclusion, flat polishing machines represent an essential investment for industries striving for precision and efficiency. Their proven track record, supported by a blend of robust engineering and expert user knowledge, makes them indispensable in achieving superior surface finishes— a testament to their critical role in modern manufacturing ecosystems. As industries continue to evolve, the versatility and reliability of flat polishing machines will undoubtedly further cement their place as a vital tool in quality surface finishing solutions.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.