The Importance of Choosing the Right Flat Bar Polishing Machine Supplier

In today’s competitive manufacturing landscape, the quality of a product often hinges on the effectiveness of its finishing processes. For industries relying on flat bars, such as metal fabrication, automotive, and construction, the necessity of a flat bar polishing machine cannot be overstated. The selection of a reputable supplier for these machines is equally crucial, as it impacts both the efficiency of operations and the quality of the final product.

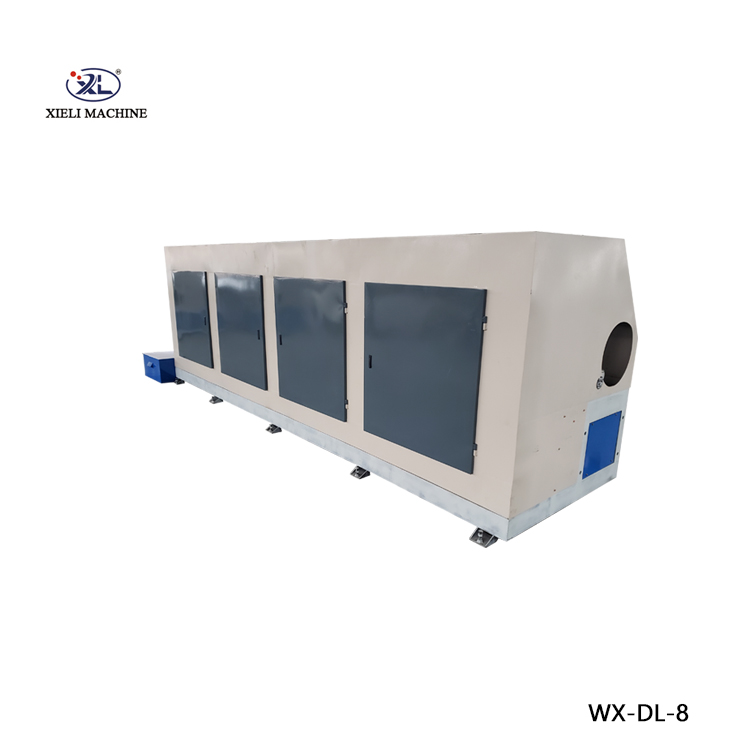

Flat bar polishing machines are designed to achieve a high degree of surface finish on flat bars. These machines not only enhance the aesthetic appeal of the metal but also improve its resistance to corrosion and wear. A quality supplier will provide machines that incorporate advanced technologies, ensuring that the polishing process is efficient, consistent, and environmentally friendly.

When searching for a flat bar polishing machine supplier, several factors should be considered. First and foremost is the experience and expertise of the supplier in the industry. Suppliers with a long-standing history often have a deep understanding of the nuances involved in polishing flat bars and can offer machines that address specific challenges. Moreover, an experienced supplier is likely to have a diverse range of machines suited for different types of materials and finishes.

flat bar polishing machine supplier

Another critical aspect is the quality of the machines provided. A reputable supplier will prioritize quality assurance and offer machines that comply with international standards. Inspecting the construction of the machines, including their durability, ease of use, and maintenance requirements, is essential. Clients should look for suppliers who provide warranties and strong after-sales support to ensure that they can resolve any issues promptly.

Furthermore, customer reviews and testimonials can provide valuable insights into a supplier's reliability and service quality. Engaging with other manufacturers who have utilized the supplier's machines can reveal information about trade-offs, performance, and long-term durability.

Finally, pricing is an unavoidable consideration. While it is tempting to choose the most affordable option, it is essential to consider the overall value. Cost-effective solutions may compromise on quality, leading to higher maintenance costs and production downtime. A reliable supplier will provide transparent pricing and offer machines that are a worthwhile investment in the long run.

In conclusion, selecting the right flat bar polishing machine supplier is vital for achieving high-quality finishes in metal production. By considering experience, machine quality, customer feedback, and pricing, manufacturers can make informed decisions that enhance productivity and product quality. Investing time and resources in choosing a competent supplier will undoubtedly pay off, ensuring the success of any metalworking operation.