Flat Bar Polishing Machine Companies A Comprehensive Overview

In the realm of metalworking, flat bar polishing machines have gained significant importance. These machines are critical for enhancing the surface finish of flat bars, ensuring that they meet industry standards for various applications. Companies that manufacture and supply flat bar polishing machines play a vital role in the metal processing sector, catering to industries like automotive, aerospace, construction, and more. This article explores the landscape of flat bar polishing machine companies, highlighting their innovations, offerings, and impact on the market.

The Importance of Polishing Machines

Flat bar polishing machines serve the essential purpose of achieving a fine finish on metal surfaces. The polishing process removes imperfections, improves corrosion resistance, and enhances aesthetic appeal. In industries where precision and quality are paramount, these machines ensure that flat bars comply with rigorous quality standards. The demand for high-quality polished surfaces has led to the growth of specialized companies focused on this niche.

Leading Companies in the Industry

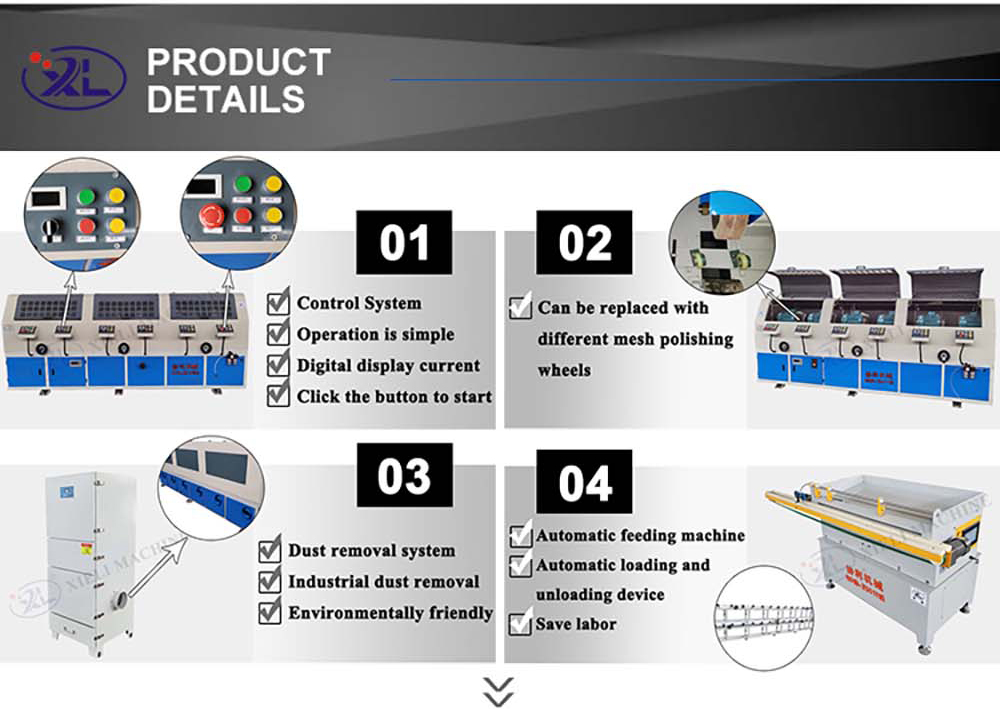

Several companies are at the forefront of the flat bar polishing machine market. Innovators like Baileigh Industrial, Belt Sanders, and Wälden have established themselves as leaders by providing robust, high-efficiency machines tailored to various needs. These companies focus on advanced engineering and technology to offer features such as adjustable speed settings, customizable polishing wheels, and automated processes that enhance productivity.

1. Baileigh Industrial Known for its commitment to quality and durability, Baileigh Industrial manufactures a range of metalworking machinery, including flat bar polishing machines. Their products are designed for both small and large operations, catering to diverse customer needs. With a strong emphasis on user-friendly controls and ergonomics, Baileigh has a reputation for reliability and efficiency.

flat bar polishing machine companies

2. Belt Sanders This company specializes in belt grinding and polishing solutions for metal surfaces. Their flat bar polishing machines are designed for heavy-duty applications, ensuring consistent results across various materials. Belt Sanders emphasizes innovation, offering machines equipped with modern technology such as dust extraction systems and programmable settings for tailored operations.

3. Wälden A prominent name in the polishing sector, Wälden combines traditional craftsmanship with cutting-edge technology. Their machines are known for precision and energy efficiency, making them a favorite among manufacturers seeking to minimize production costs while maintaining high-quality output.

Innovations in Flat Bar Polishing Machines

The flat bar polishing machine market is witnessing technological advancements that are transforming operations. Automation plays a crucial role, as many companies are integrating robotics and AI into their machines. This not only boosts efficiency but also reduces human error, ensuring a consistent output.

Moreover, companies are focusing on sustainability by developing environmentally friendly machines. These innovations include energy-efficient motors, waste-reduction technologies, and materials that minimize ecological impact. As industries increasingly prioritize environmental responsibility, such features are becoming essential selling points.

Conclusion

The landscape of flat bar polishing machine companies is characterized by innovation, sustainability, and a commitment to quality. As the demand for high-quality metal surfaces continues to rise across various sectors, these companies play a crucial role in delivering advanced solutions that meet the evolving needs of the industry. By investing in technology and embracing sustainable practices, flat bar polishing machine manufacturers are not just enhancing the quality of their products but also contributing to a more responsible and efficient metalworking industry. The future looks promising for these companies as they navigate the challenges and opportunities in the market, shaping the next generation of metal finishing technologies.