The Role of Centerless Grinder Wheels Suppliers in Precision Manufacturing

In modern manufacturing, precision and efficiency are paramount. One of the essential tools that aid in achieving these goals is the centerless grinder. This machine is widely used to shape and finish workpieces with high accuracy, making it a staple in industries ranging from automotive to aerospace. Central to the functionality of a centerless grinder are its grinding wheels, and this brings us to the importance of centerless grinder wheels suppliers.

Centerless grinding is a unique process that holds workpieces between two wheels without the need for a dedicated fixture. This allows for continuous workpiece processing, which drastically enhances productivity compared to traditional grinding methods. The grinding wheels are crucial in this setup, as they determine the effectiveness of the grinding process. Suppliers of these wheels play a vital role in providing the right tools necessary for achieving high tolerances and surface finishes.

One of the primary aspects that set apart quality centerless grinder wheels suppliers is their ability to offer a diverse range of options. There are different types of grinding wheels tailored for various applications, including those that cater to specific materials such as steel, aluminum, and plastics. A reputable supplier should provide grinding wheels with various sizes, bond types, and grit specifications. This allows manufacturers to select the right wheel for their specific application, ensuring optimal performance and minimizing wear on the equipment.

In addition to a diverse product range, quality assurance is another critical factor that distinguishes leading centerless grinder wheels suppliers. High manufacturing standards and rigorous testing processes ensure that the wheels meet specific performance metrics. Suppliers often collaborate with manufacturers to develop custom solutions, addressing unique challenges presented by particular products or materials. This level of customization is essential for industries that require precise specifications and reliability in their grinding processes.

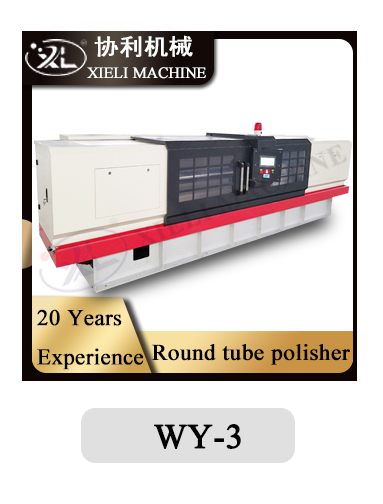

centerless grinder wheels suppliers

Moreover, efficient supply chain management is another hallmark of a reputable supplier. In the fast-paced world of manufacturing, downtime can lead to significant losses. Therefore, suppliers must maintain adequate stock levels and have a swift order fulfillment process. Establishing a strong relationship with a supplier can ensure that manufacturers receive timely deliveries of grinding wheels, thereby keeping production smoothly running without interruptions.

Another important aspect that suppliers can offer is technical support and consultation. Knowledgeable suppliers can provide valuable insights into the selection and application of grinding wheels. They can guide manufacturers on best practices to enhance grinding efficiency, longevity of the wheels, and overall operational effectiveness. This support is particularly beneficial for companies venturing into centerless grinding for the first time or those seeking to optimize their existing processes.

Sustainability is also becoming increasingly significant in manufacturing. Forward-thinking suppliers are now focusing on providing eco-friendly grinding wheels and promoting practices that reduce waste. Suppliers that adopt sustainable manufacturing processes not only contribute positively to the environment but also resonate with the growing base of environmentally-conscious consumers.

In conclusion, centerless grinder wheels suppliers play a crucial role in the landscape of precision manufacturing. Their ability to provide diverse products, ensure quality, maintain efficient supply chains, offer technical support, and embrace sustainability enhances their relevance in the highly competitive market. As industries continue to evolve, the synergy between manufacturers and their suppliers will remain a foundational element in achieving excellence and innovation in manufacturing processes.