Understanding Centerless Grinder Quotations A Guide for Factories

In the fast-paced world of manufacturing, precision and efficiency are paramount. One of the vital machines utilized in many industrial settings is the centerless grinder. This machine is essential for producing high-quality cylindrical components by removing material from workpieces without the need for a centering device. Given its importance, acquiring a centerless grinder at the right price is crucial for the operational budget of any factory. This article will delve into the factors influencing centerless grinder quotations, helping manufacturers to make informed purchasing decisions.

What is a Centerless Grinder?

A centerless grinder is a type of cylindrical grinder that uses a different approach to grinding. Unlike traditional grinders that fix the workpiece between centers, centerless grinders utilize two rotating wheels – a grinding wheel and a regulating wheel – to hold and grind the workpiece. This design allows for continuous production, as parts can be fed into one side and exit the other without interruption. This efficiency translates into significant cost savings over time, making centerless grinders a popular choice in various applications, including automotive, aerospace, and medical industries.

Factors Influencing Quotations

When factories seek quotations for centerless grinders, several critical factors come into play

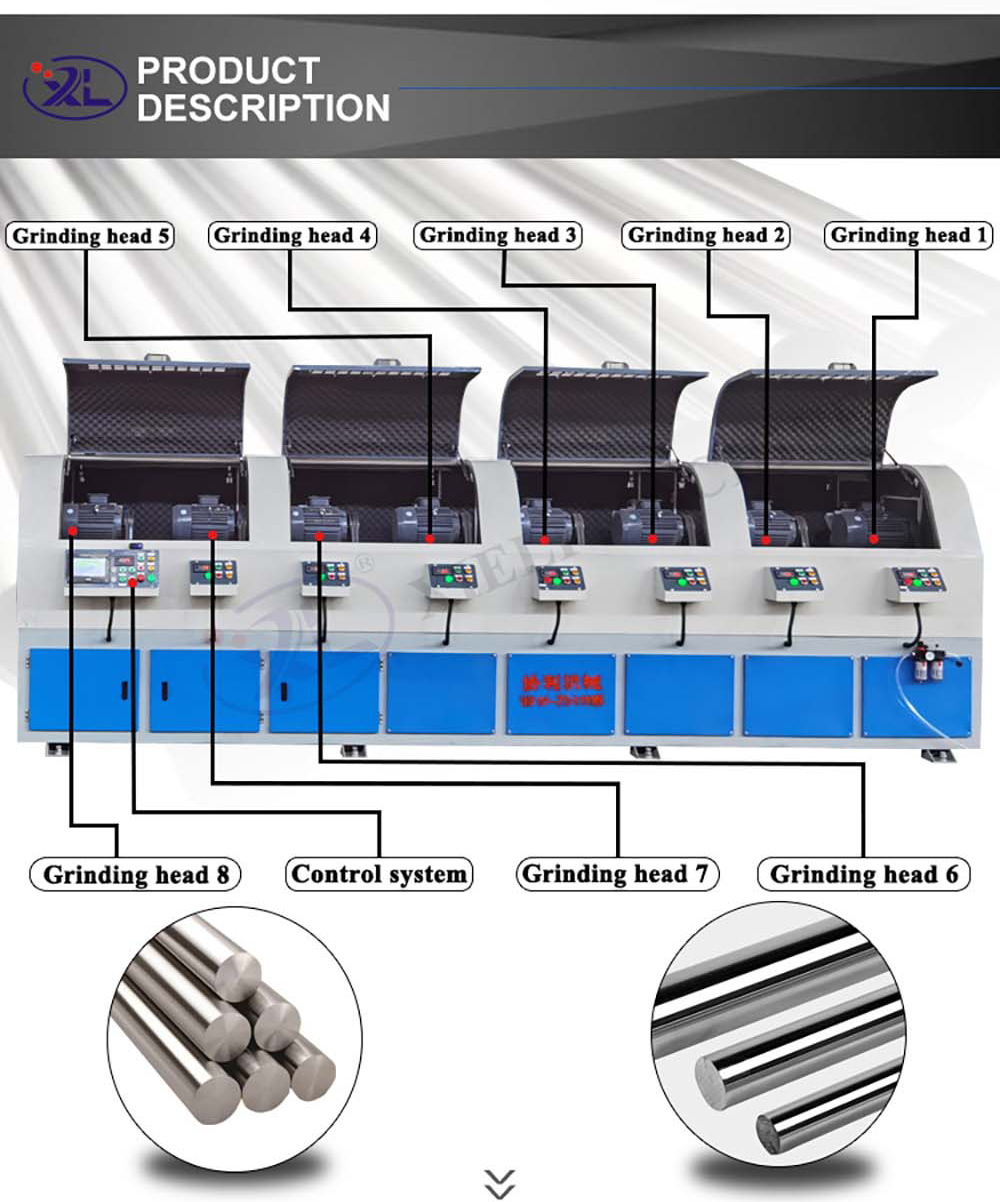

1. Specifications and Features The type of centerless grinder—whether it is a through-feed, in-feed, or step-grinding model—will heavily influence the price. Additional features such as automation capabilities, programmable controls, and advanced cooling systems also contribute to the overall cost. Factories need to assess their specific needs to ensure they receive accurate quotations that align with their operational requirements.

centerless grinder quotation factories

2. Brand and Quality Reputation in the industry often correlates with price. Well-known brands that are recognized for quality and reliability may command a higher cost, while lesser-known brands might offer more competitive pricing. However, choosing a reputable brand can lead to long-term savings due to better service and durability.

3. Customization Many manufacturers offer custom solutions designed to meet unique requirements. Customization can encompass various features, including size, shape, and additional accessories. While customized grinders may come at a premium, they can ultimately deliver significant efficiency gains that justify the initial investment.

4. Volume of Purchase Factories looking to purchase multiple machines often find they can negotiate better terms and prices with manufacturers. Bulk purchases usually lead to price reductions, making it beneficial for businesses anticipating high production needs.

5. Warranty and After-Sales Service Quotations should also account for warranty periods and after-sales services, which can vary significantly among manufacturers. A longer warranty and reliable service support can mitigate risks associated with breakdowns, making higher-priced machines with robust service packages more appealing.

6. Shipping and Installation Costs The final quote should include shipping fees and any installation requirements. Depending on the manufacturer’s location and factory setup, these costs can vary. Factories should clarify this with suppliers to avoid unexpected expenses in the procurement process.

Conclusion

Obtaining quotations for centerless grinders is a critical process that requires careful consideration of several factors, from specifications and brand reputation to volume discounts and after-sales support. By understanding these elements, factories can navigate the procurement process more effectively and select a machine that not only fits their budget but also enhances their production capabilities. Ultimately, a well-informed purchase decision can lead to improved efficiency, better product quality, and significant long-term savings. As the manufacturing landscape continues to evolve, investing in the right equipment is more important than ever for maintaining a competitive edge.