Unlocking Efficiency Filmatic Solutions for Centerless Grinder Machines

In the ever-evolving landscape of manufacturing, precision remains paramount. Among the array of machining processes, centerless grinding stands out for its ability to achieve high tolerance levels and efficient material removal. Companies striving to enhance their production capabilities are increasingly looking towards innovative solutions like Filmatic for their centerless grinder machines. This article delves into the myriad of benefits that Filmatic technology can provide, transforming traditional grinding processes into seamless operations.

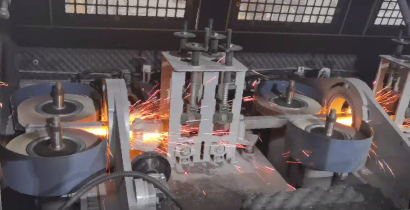

Centerless grinding is a method where the workpiece is supported on its outside diameter, resting between a grinding wheel and a regulating wheel. This setup facilitates continuous cutting and allows for high levels of accuracy. However, achieving optimal performance in centerless grinding requires a robust system that minimizes downtime and enhances operational efficiency. This is where Filmatic’s cutting-edge technology comes into play.

Filmatic offers a range of solutions specifically designed to address the challenges faced by manufacturers using centerless grinder machines. One notable advantage is the precision-engineered components that ensure sustained performance. With tightly controlled tolerances, Filmatic parts are designed to enhance the grinding process, delivering superior surface finishes and maintaining the integrity of the workpiece.

Another significant benefit of incorporating Filmatic solutions is the reduction of maintenance requirements. Traditional centerless grinders often demand frequent servicing and extensive downtime. However, Filmatic’s advanced materials and designs are engineered for longevity, significantly decreasing wear and tear. As a result, manufacturers can maintain higher productivity levels without the constant disruption of maintenance schedules.

filmatic for centerless grinder machine quotes

Moreover, the integration of Filmatic solutions allows for greater flexibility in production. Different industries require various grinding specifications, and the adaptability of Filmatic technology enables machines to easily switch between tasks. This versatility is invaluable in today’s fast-paced market, where customization and rapid response to customer needs are critical.

Filmatic’s commitment to innovation also encompasses the realm of automation. With the rise of Industry 4.0, the demand for smarter manufacturing processes is more pronounced than ever. Filmatic equips centerless grinder machines with automation capabilities that optimize workflow and reduce manual intervention. This not only enhances precision but also minimizes the potential for human error, resulting in more consistent output.

In addition to these operational advantages, adopting Filmatic solutions can have a positive impact on the overall bottom line. While there might be an initial investment to upgrade or retrofit existing grinders with Filmatic technologies, the long-term savings from reduced downtime, lower maintenance costs, and improved productivity significantly outweigh these costs. In essence, Filmatic solutions can transform a centerless grinding operation into a highly efficient and profitable endeavor.

In conclusion, as the manufacturing industry continues to push the boundaries of technology and efficiency, solutions like Filmatic for centerless grinder machines are leading the way. Their emphasis on precision, durability, flexibility, and automation positions them as an indispensable asset for any company looking to optimize its grinding processes. Embracing Filmatic's innovations could very well be the key to unlocking unprecedented levels of productivity and competitiveness in the market. For manufacturers aiming to thrive in a challenging economic environment, the integration of Filmatic solutions represents not just an enhancement, but a strategic advantage.