The Importance of Stainless Tube Polishing Machines in Modern Manufacturing

In the realm of modern manufacturing, the demand for high-quality, aesthetically appealing products has never been higher. This trend is particularly evident in industries such as automotive, aerospace, medical, and food processing, where stainless steel tubes play a crucial role. To meet these demands, the stainless tube polishing machine has emerged as a vital tool in the production process, ensuring that stainless steel tubes are not only functional but also visually appealing.

Why Polish Stainless Steel Tubes?

Stainless steel is favored for its durability, corrosion resistance, and strength, making it an ideal material for various applications. However, raw stainless steel tubes often have a rough surface, which can attract contaminants, corrode over time, and diminish the overall aesthetic of the product. Polishing brings several benefits

1. Enhanced Aesthetic Appeal Polished tubes have a reflective surface that enhances their visual appeal. This is particularly important in industries where the appearance of the product influences buying decisions.

2. Improved Corrosion Resistance A smooth surface is less likely to harbor bacteria and other contaminants, making polished stainless steel tubes a healthier option for industries such as food processing and pharmaceuticals.

3. Easier Cleaning and Maintenance Polished surfaces can be cleaned more easily than their unpolished counterparts, which is crucial in maintaining hygiene and functionality in sensitive environments.

4. Improved Mechanical Properties The polishing process can also enhance the mechanical properties of the tubes, including their fatigue strength and overall performance.

Features of Stainless Tube Polishing Machines

Stainless tube polishing machines come in various designs and configurations, tailored to meet the specific needs of different industries. Here are some key features

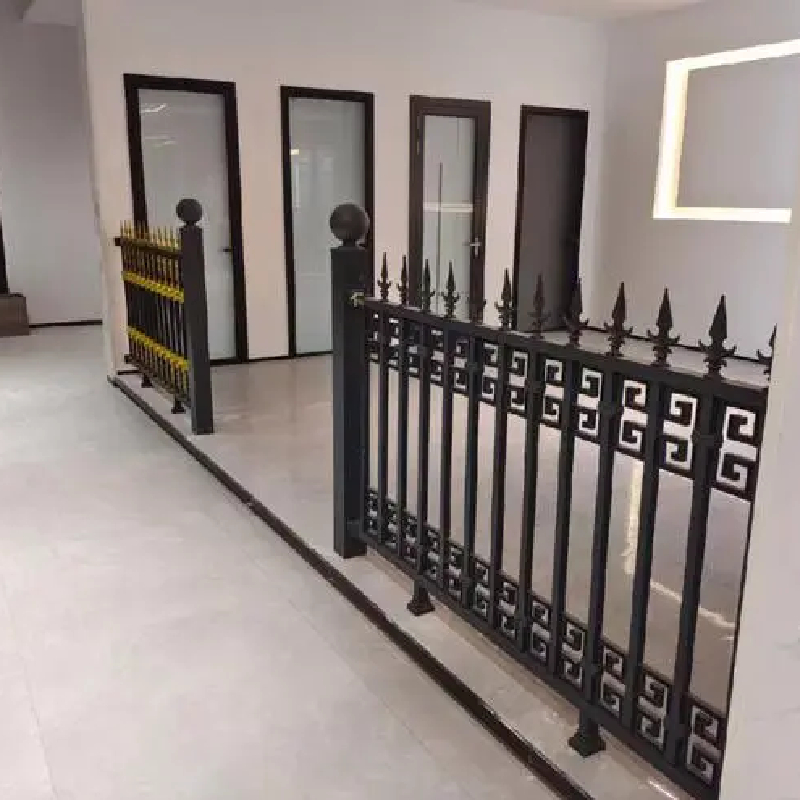

famous stainless tube polishing machine

1. Automated Processes Many modern polishing machines are fully automated, allowing for high throughput rates while reducing labor costs. Automation minimizes the risk of human error, ensuring a consistent finish on each tube.

2. Versatility These machines can handle various tube sizes and shapes, making them suitable for diverse applications, from small-diameter tubes used in medical devices to larger tubes utilized in construction and transportation.

3. Adjustable Parameters Users can adjust parameters such as speed, pressure, and polishing compounds, allowing for customization based on the specific requirements of the material and desired finish.

4. Integrated Inspection Systems Advanced polishing machines often incorporate inspection systems to assess the quality of the finish in real-time, ensuring that only tubes meeting the required standards proceed to the next stage of production.

The Future of Stainless Tube Polishing Machines

As technology continues to evolve, the future of stainless tube polishing machines looks promising. Developments in robotics, artificial intelligence, and machine learning are paving the way for even more sophisticated machines capable of performing complex polishing tasks with little to no human intervention.

Additionally, there is a growing emphasis on sustainability in manufacturing processes. Manufacturers are seeking solutions that reduce waste and energy consumption. Future polishing machines are expected to employ eco-friendly polishing compounds and energy-efficient technologies, aligning with global sustainability goals.

Conclusion

In conclusion, stainless tube polishing machines are indispensable in modern manufacturing, ensuring that stainless steel tubes meet the highest standards of quality, aesthetics, and functionality. As industries continue to evolve, these machines will play a critical role in shaping the future of manufacturing, driving innovation, and meeting the ever-increasing demands for premium products. The investment in advanced polishing technology not only enhances the production process but also contributes to the overall success of manufacturing operations across various industries.