The Rise of Famous SS Tube Polishing Machines Enhancing Surface Finishing Technology

In today's manufacturing landscape, the importance of surface finishing cannot be underestimated. Whether in the automotive, aerospace, or food and beverage industry, the quality of a product's surface plays a critical role in its functionality and appeal. Among various surface finishing techniques, tube polishing stands out as a pivotal process for achieving a smooth, aesthetically pleasing, and corrosion-resistant surface on stainless steel tubes. With this need comes the innovation of specialized machinery, notably the famous SS (stainless steel) tube polishing machines.

The Significance of Tube Polishing

Stainless steel is renowned for its durability, resistance to corrosion, and hygienic properties, making it an ideal material for various applications. However, raw stainless steel often comes with a rough texture that can harbor contaminants and negatively affect its appearance. Tube polishing machines effectively eliminate these imperfections, resulting in a polished finish that enhances the tube's appearance and functional characteristics.

The demand for polished stainless steel tubes has soared in recent years, particularly in industries where hygiene is paramount, such as food processing and pharmaceuticals. Moreover, polished surfaces reflect light, giving products a more appealing look, which is particularly important when it comes to aesthetic markets. This demand has fueled the development and popularity of sophisticated tube polishing equipment.

The Mechanism of SS Tube Polishing Machines

Famous SS tube polishing machines come equipped with various features that facilitate efficient polishing processes. Typically, these machines utilize a combination of mechanical polishing techniques and advanced abrasive materials to achieve the desired finish. The polishing process involves several stages, including surface preparation, polishing, and final inspection.

1. Surface Preparation Before the actual polishing begins, it is crucial to prepare the surface of the tube. This usually includes cleaning the tubes to remove any dirt, grease, or other contaminants that could interfere with the polishing process.

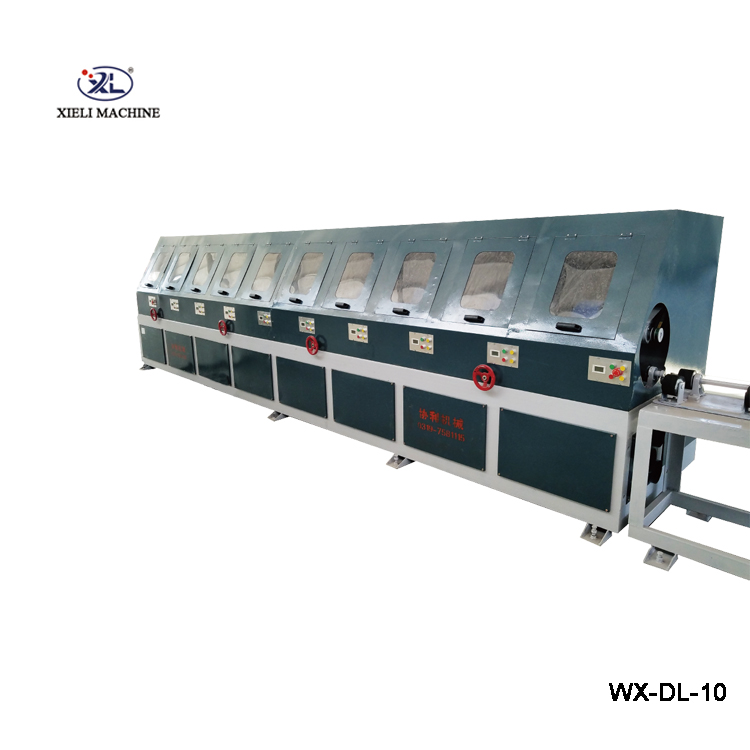

2. Polishing Once the tubes are prepped, they are subjected to the polishing process. Famous SS tube polishing machines often feature multiple polishing heads, which can be adjusted to accommodate different tube sizes and shapes. Using abrasive belts or pads, these machines refine the surface, gradually smoothing it out and enhancing its shine.

famous ss tube polishing machine

3. Final Inspection After polishing, the tubes undergo a rigorous inspection process to ensure that every inch meets industry standards. This includes checking for consistency in finish and identifying any remaining imperfections that might need additional attention.

Advantages of Using SS Tube Polishing Machines

Investing in a quality tube polishing machine offers several benefits to manufacturers

- Increased Efficiency Automated polishing machines can significantly reduce processing time compared to manual polishing methods. They enable high-volume production without sacrificing quality.

- Consistent Quality With precise control over the polishing process, these machines ensure that every tube receives the same level of attention, resulting in uniform quality across products.

- Cost-Effectiveness Although the initial investment in a polishing machine may seem steep, the long-term savings in labor and material costs, combined with improved product quality, make it a worthwhile investment.

- Enhanced Aesthetic Appeal The polished finish provided by these machines is not only visually attractive but also adds value to the end product. This enhanced appeal can lead to higher customer satisfaction and potentially increase sales.

Conclusion

The evolution of famous SS tube polishing machines represents a significant advancement in surface finishing technology. As industries continue to prioritize hygiene, aesthetic appeal, and product quality, the demand for effective polishing solutions is likely to grow. These machines combine efficiency, precision, and versatility, making them indispensable tools in various manufacturing settings. For businesses aiming to maintain a competitive edge, investing in advanced tube polishing technology is not just an option—it's a necessity. As we look to the future, the role of tube polishing machines will undoubtedly continue to expand alongside advancements in manufacturing technologies, further solidifying their position as a pillar of surface finishing excellence.