The Importance of Square Tube Grinding Machines in Modern Manufacturing

In the realm of modern manufacturing, precision and efficiency are paramount, and nowhere is this more evident than in the processing of square tubes. Square tube grinding machines have become essential equipment in various industries, including construction, automotive, and structural engineering, where the need for high-quality finishing and accurate dimensions is critical.

Understanding Square Tube Grinding Machines

Square tube grinding machines are specialized tools designed to grind and finish square tubes made from a variety of materials, including steel, aluminum, and stainless steel. These machines utilize abrasive belts or wheels to remove material from the surface of tubes, achieving smoother finishes and tighter tolerances. The grinding process involves removing imperfections from the tube surface, making it suitable for further processing or final applications.

One of the key advantages of square tube grinding machines is their ability to enhance the aesthetic and functional qualities of metal tubes. The grinding process minimizes surface roughness, which not only improves visual appeal but also increases resistance to corrosion and wear. Moreover, a smoother surface enhances the adhesion properties of coatings applied afterward, whether they're paint, powder coating, or galvanization.

Features and Technologies in Modern Square Tube Grinding Machines

Modern square tube grinding machines are equipped with advanced features that improve their functionality and efficiency. These machines come with adjustable speed settings, allowing operators to select the ideal grinding speed based on the material being processed. This level of control ensures optimal results while preventing overheating and unwanted damage to the tube's surface.

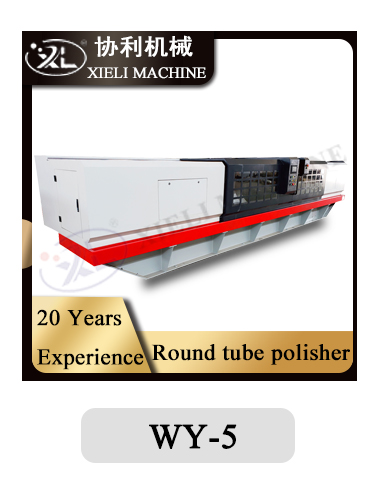

famous square tube grinding machine

Another significant technological advancement in these machines is the integration of automated systems and CNC (Computer Numerical Control) technology. CNC square tube grinding machines can perform complex grinding operations with minimal human intervention. They offer precision cutting, consistent quality, and the ability to process multiple tubes of varying sizes without the need for constant readjustment, drastically reducing production times.

The Applications of Square Tube Grinding Machines

The applications of square tube grinding machines are extensive. In the construction industry, square tubes are often used in the framework of buildings and other structures. A well-finished square tube not only contributes to the overall integrity of the structure but also enhances its visual appeal.

In the automotive sector, these machines are utilized to produce high-quality components that can withstand the rigors of use. For example, square tubes used in vehicle frames or roll cages must be precisely finished to ensure safety and performance. Manufacturers rely on quality grinding processes to meet stringent regulations and standards, which is where these machines play a pivotal role.

Moreover, industries like furniture manufacturing and metal fabrication also benefit from the use of square tube grinding machines. High-quality finishes can mean the difference between a product that stands the test of time and one that deteriorates quickly.

Conclusion

In conclusion, square tube grinding machines are invaluable assets in contemporary manufacturing. Their ability to produce high-quality finishes, improve material properties, and reduce production time makes them a staple in various industries. As technology continues to advance, we can expect further enhancements in the capabilities of these machines, leading to even greater levels of efficiency and precision in tube processing. For manufacturers looking to maintain a competitive edge in the market, investing in advanced square tube grinding technology is not just beneficial; it is essential.