The Famous Royal Master Centerless Grinder for Sale A Comprehensive Overview

In the world of precision machining, the efficiency and accuracy of equipment play a crucial role in production. Among the myriad of tools available to modern manufacturers, the centerless grinder stands out for its unique capacity to grind cylindrical parts without the need for a spindle. One of the most recognized names in this field is the Royal Master Centerless Grinder, which has built a reputation for excellence in grinding technology. In recent years, there has been a rising interest in purchasing second-hand machinery, including the Royal Master models. This article will explore the features, advantages, and the market for these grinders, providing insights for potential buyers.

Understanding Centerless Grinding

Before delving into the specific attributes of the Royal Master Centerless Grinder, it is essential to understand the concept of centerless grinding itself. This process utilizes three main components the grinding wheel, the regulating wheel, and the workpiece, which is supported on an adjustable work rest blade. Unlike traditional grinders, centerless grinders do not require the workpiece to be mounted on a spindle. Instead, they hold the workpiece in place through a combination of the grinding wheel’s pressure and the regulating wheel's rotation. This setup allows for continuous grinding, enabling high production rates and exceptional precision.

Features of the Royal Master Centerless Grinder

The Royal Master Centerless Grinder is known for its innovative design and advanced features. One of the hallmark distinctions of this machine is its versatility. It is capable of accommodating a wide range of part sizes and shapes, making it ideal for various applications, from medical devices to precision automotive components. The machine is engineered to provide tight tolerances and exceptional finish quality, which are critical for industries that demand precision.

Royal Master grinders are equipped with state-of-the-art control systems that allow operators to customize grinding parameters easily. This capability ensures that users can achieve the desired specifications without extensive downtime. Additionally, many models feature a compact footprint and can be customized with various tool options, including grinding and dressing systems, to meet specific production needs.

Advantages of Using a Royal Master Centerless Grinder

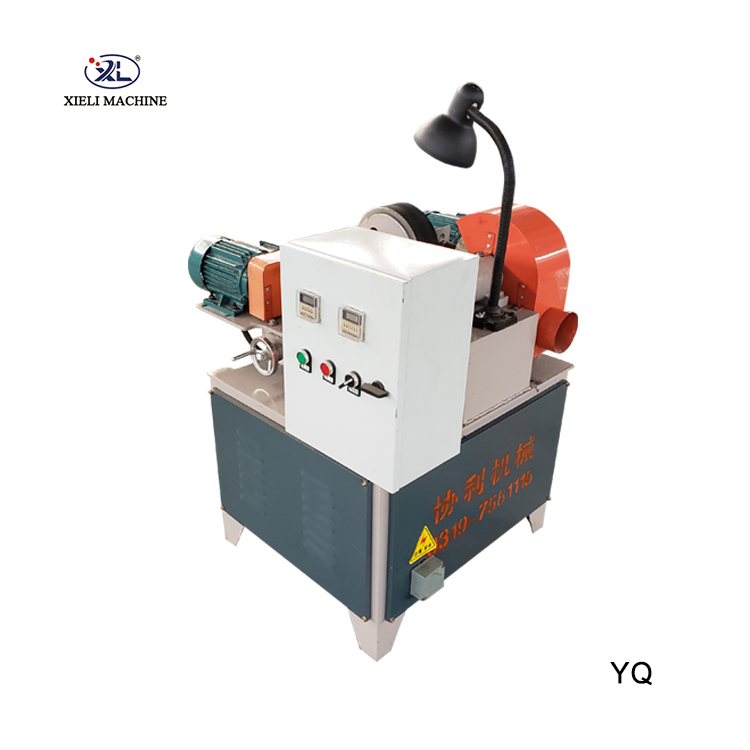

famous royal master centerless grinder for sale

There are numerous advantages to incorporating a Royal Master Centerless Grinder into a manufacturing setup. Firstly, the machine's design enhances productivity; operators are able to grind parts continuously, reducing cycle times significantly. This increased efficiency translates to lower production costs.

Secondly, the precision offered by these grinders minimizes material waste and rework, which further optimizes manufacturing processes. For industries such as medical device manufacturing, where precision is paramount, the Royal Master Centerless Grinder provides a reliable solution for achieving stringent quality standards.

Moreover, the ease of operation and maintenance makes it an attractive option for manufacturers. Royal Master machines require less operator intervention compared to traditional grinding methods, which can lead to reduced labor costs and improved overall productivity.

The Market for Royal Master Grinders

As the demand for high-quality machining tools continues to rise, the market for used Royal Master Centerless Grinders has become increasingly competitive. Many businesses, particularly startups and small manufacturers, find the cost savings associated with purchasing second-hand machinery appealing. Buying a used grinder can significantly lower upfront investment while still providing access to top-tier grinding technology.

When considering the purchase of a used Royal Master grinder, it is crucial for buyers to ensure they are acquiring a machine that has been well maintained and meets their specific operational requirements. Many distributors and auction houses offer warranties or guarantees, which can provide additional peace of mind.

Conclusion

In conclusion, the Royal Master Centerless Grinder stands out in the machining landscape for its advanced capabilities and versatility. With its ability to enhance productivity and precision, coupled with a growing market for both new and used models, it represents an essential tool for manufacturers looking to elevate their processes. Whether you are considering investing in a new grinder or exploring the second-hand market, the Royal Master grinder is undoubtedly a worthy consideration for any company dedicated to achieving excellence in production.