The Evolution and Significance of the Famous Paragon Centerless Grinding Machine

In the realm of precision engineering, few machines have stood the test of time like the Paragon centerless grinding machine. Renowned for its capability to deliver high accuracy and superior surface finishes, the Paragon model has become a staple in various industries, including automotive, aerospace, and manufacturing. This article delves into the evolution, features, and significance of the Paragon centerless grinding machine, showcasing why it has earned its place in the annals of industrial machinery.

Historical Background

The concept of centerless grinding was first introduced in the early 20th century as industries began demanding machines that could efficiently produce cylindrical parts with minimal human intervention. The Paragon brand emerged as a pioneer in this field, utilizing innovative designs that catered to the needs of manufacturers seeking increased productivity and precision. Over the years, the Paragon centerless grinding machine evolved through rigorous research and development, incorporating advanced technology and automation.

Distinctive Features

At the core of the Paragon centerless grinding machine's success are its distinctive features. Unlike traditional grinding machines, centerless grinders do not require the workpiece to be mounted between centers. Instead, the workpiece is supported by a work rest and driven by a wheel. This design enables high-speed, continuous operation, making it possible to grind multiple pieces simultaneously with greater efficiency.

One notable feature of the Paragon model is its versatility. It can accommodate a wide range of workpiece sizes and materials, from small components like pins to larger parts used in industrial applications. Moreover, the machine offers various grinding options, including through-feed, in-feed, and end-feed grinding, allowing manufacturers to tailor their processes based on specific requirements.

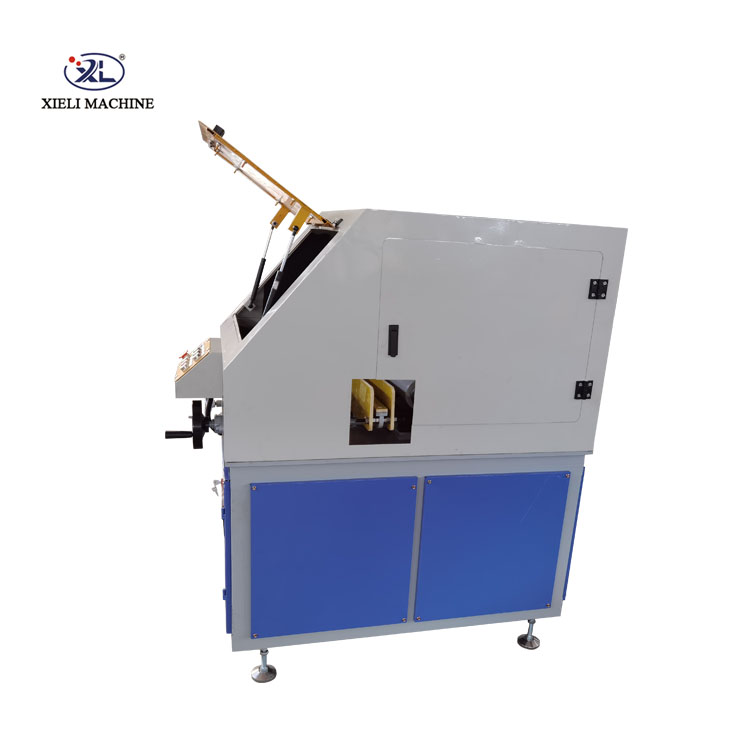

famous paragon centerless grinding machine

Another key aspect is the machine's precision engineering, which is essential for industries where tolerances are critical. The Paragon centerless grinding machine is equipped with advanced control systems that ensure consistency and accuracy throughout the grinding process. This level of precision minimizes waste and enhances overall productivity, making it a cost-effective choice for manufacturers.

Applications in Various Industries

The influence of the Paragon centerless grinding machine extends across a multitude of sectors. In the automotive industry, it is instrumental in producing components such as crankshafts, camshafts, and bushings. These parts necessitate a high degree of accuracy and surface finish, making centerless grinding the ideal method of production.

Similarly, in the aerospace sector, where safety and performance are paramount, the Paragon machine is utilized for grinding critical components that require stringent adherence to specifications. The ability to produce lightweight yet durable parts contributes to enhancing aircraft efficiency and safety.

In the manufacturing realm, the Paragon centerless grinder serves various purposes, from creating medical devices to producing electronic components. Its adaptability to different materials, including metals and polymers, showcases its significance as a multifaceted tool in modern manufacturing processes.

Conclusion

The Paragon centerless grinding machine has made substantial contributions to the field of precision engineering. Its evolution from a simple grinding concept to a sophisticated piece of machinery symbolizes the advancements in technology and the growing demands of various industries. As manufacturers continue to seek ways to improve productivity and precision, the Paragon model remains at the forefront, embodying the principles of innovation and excellence. The legacy of this remarkable machine is a testament to its lasting impact on the manufacturing landscape, ensuring that it will continue to play a crucial role in the industry for years to come.