The Importance of Handheld Tube Polishing Machines in Modern Manufacturing

In the realm of modern manufacturing, efficiency and quality are paramount. Among the numerous tools and technologies utilized in this sector, the handheld tube polishing machine has emerged as a significant player, transforming how metal surfaces are finished and maintained. This innovative machine caters to various industries, offering a reliable solution for enhancing the aesthetic appeal and functional quality of tubular metal parts.

Handheld tube polishing machines, as the name suggests, are portable devices designed specifically for polishing and finishing tubular materials. These machines are notable for their versatility, allowing operators to work on a wide range of materials such as stainless steel, aluminum, and brass. The ease of use and flexibility they offer make them a favored choice for fabricators, welders, and metal finishing professionals.

One of the primary benefits of handheld tube polishing machines is their ability to produce a high-quality mirror finish that enhances the appearance of metal products. In industries where aesthetics play a crucial role, such as automotive, aerospace, and architecture, the polished look of metal components can significantly impact the overall quality and customer perception of the final product. A polished surface not only looks appealing but also helps prevent corrosion, improving the longevity of the product.

Furthermore, handheld tube polishing machines are designed for efficiency. With advancements in technology, current models have become more powerful and user-friendly. Many come equipped with variable speed controls, allowing operators to adjust the polishing speed according to the specific requirements of the job. This adaptability ensures that metal surfaces can be polished effectively without the risk of overheating or damaging the material.

famous hand held tube polishing machine

In addition to efficiency and aesthetics, portability is another significant advantage of handheld tube polishing machines. Unlike traditional polishing methods that often require bulky equipment and extensive setups, handheld machines allow operators to work in tight spaces and on-site, reducing the time and labor involved in the finishing process. This feature is particularly beneficial in industries such as construction and repair, where components must be polished directly at the job site.

Moreover, the ergonomics of handheld tube polishing machines have been a significant focus in recent designs. Manufacturers are increasingly prioritizing user comfort, incorporating features such as lightweight materials, comfortable grips, and reduced vibration. These enhancements not only improve the user experience but also contribute to safety and productivity, allowing operators to work for extended periods without fatigue.

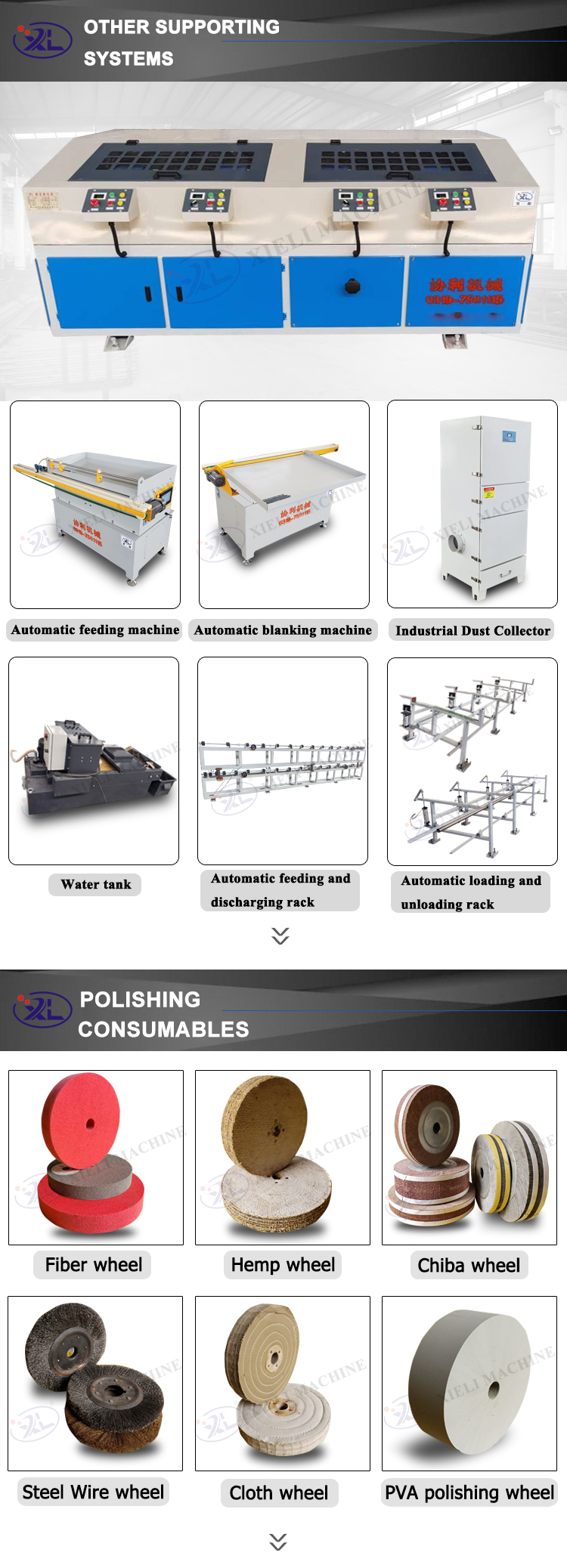

Environmental considerations have also entered the conversation surrounding polishing machines. As industries strive to adopt more sustainable practices, many modern handheld tube polishing machines come equipped with dust collection systems to minimize airborne particles and debris. This is crucial not only for worker safety but also for compliance with health and safety regulations.

In conclusion, handheld tube polishing machines have become essential tools in modern manufacturing, serving a variety of industries. Their ability to deliver high-quality finishes, combined with their efficiency, portability, and ergonomic design, make them indispensable for professionals involved in metal fabrication and finishing. As technology continues to advance, these machines will likely evolve further, offering even more innovative solutions for the challenges faced in the manufacturing world. Embracing this technology not only enhances product quality but also contributes to a more efficient and sustainable manufacturing process.