The Evolution of Automatic Metal Polishing Machines A Gateway to Enhanced Productivity

In the ever-evolving landscape of industrial manufacturing, the quest for efficiency and quality has led to the development of sophisticated machinery

. Among these innovations, automatic metal polishing machines stand out as crucial tools in metal finishing processes. These machines not only enhance the aesthetic appeal of metal surfaces but also improve their resistance to corrosion and wear, thereby extending the lifespan of products.Historically, metal polishing was a labor-intensive manual process, often requiring significant time and skilled labor. Artisans would painstakingly polish metal surfaces using cloths and various abrasives, achieving a shine through sheer effort. However, as industries grew and the demand for high-quality finishes increased, it became clear that a more efficient solution was necessary. This need spurred the development of automatic polishing machines, which revolutionized the way manufacturers approach metal finishing.

Automatic metal polishing machines employ advanced technologies and engineering to streamline the polishing process. These machines are equipped with programmable controls that allow for precise adjustments to polishing speed, pressure, and duration. This level of control ensures uniform results and significantly reduces the time required to achieve the desired finish. As a result, manufacturers can increase their output, reduce labor costs, and improve the quality of their products.

One of the most significant advantages of automatic metal polishing machines is their ability to handle a wide variety of materials. Whether it’s stainless steel, aluminum, or brass, these machines can be configured to effectively polish different types of metals. This versatility makes them invaluable in industries such as automotive, aerospace, and consumer goods, where diverse metal components are commonly used.

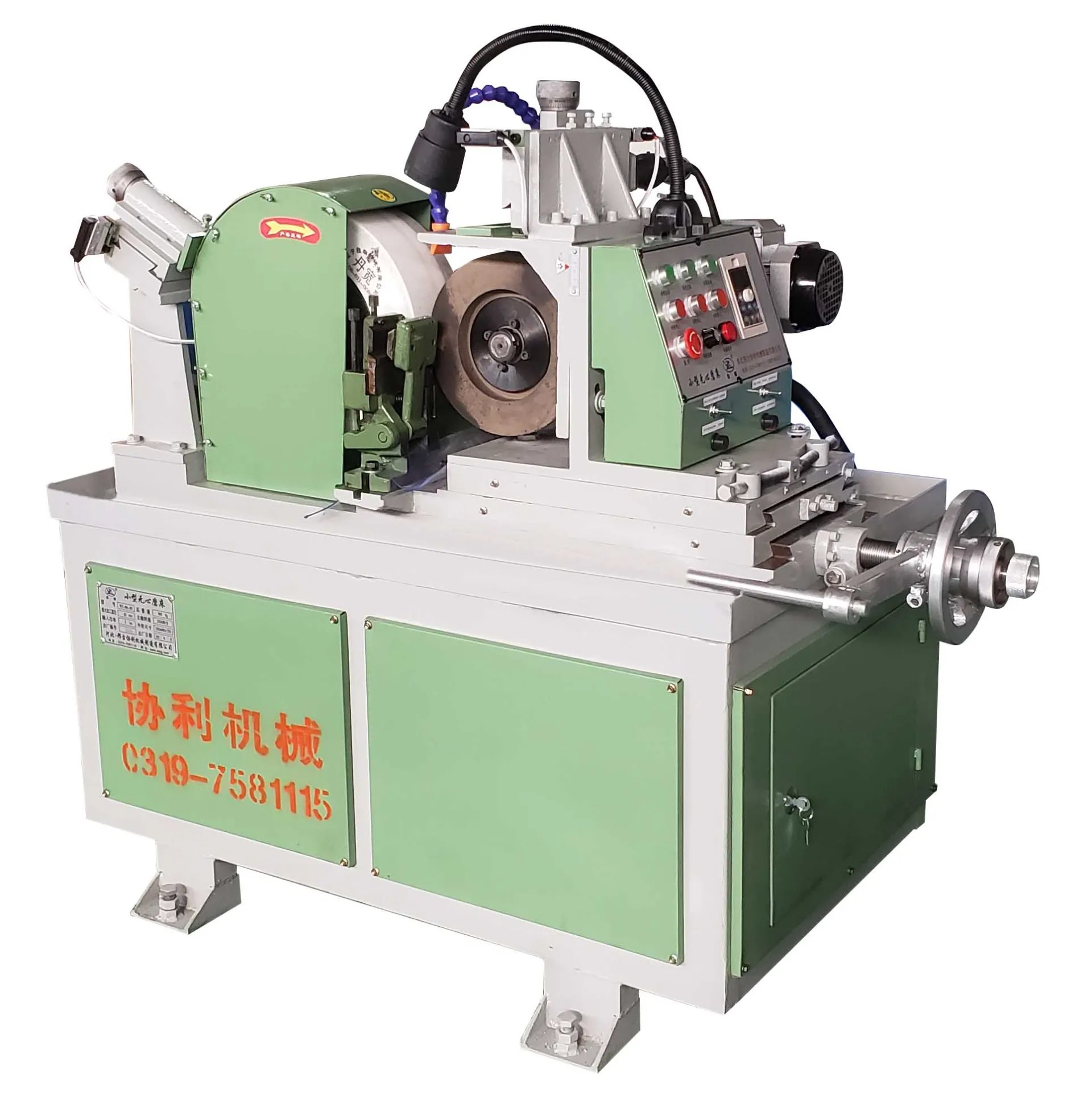

famous automatic metal polishing machine

Furthermore, the integration of automation and robotics into polishing systems has further enhanced their efficiency. Automated systems can be programmed to perform multiple processes in a single cycle, including surface preparation, polishing, and finishing. This not only streamlines operations but also minimizes the risk of human error. For instance, robots equipped with polishing heads can navigate complex geometries and hard-to-reach areas, ensuring an even polish across intricate designs.

In addition to operational efficiency, the use of automatic metal polishing machines can have a positive impact on sustainability. Traditional polishing methods often generate significant waste, including excess abrasives and solvents that can be harmful to the environment. Automatic machines are designed to minimize waste and often incorporate recycling systems that can reclaim materials for reuse. This sustainable approach aligns with the growing emphasis on environmentally friendly practices in manufacturing.

As technology continues to advance, the future of automatic metal polishing machines looks promising. Innovations such as artificial intelligence and machine learning are being integrated into these systems, allowing for adaptive polishing techniques that can learn from previous operations to optimize performance further. This level of intelligence ensures that manufacturers can maintain high standards of quality while also adapting to the ever-changing demands of the market.

In conclusion, automatic metal polishing machines have transformed the landscape of metal finishing. By increasing efficiency, versatility, and sustainability, these machines play a pivotal role in modern manufacturing. As industries continue to evolve, the importance of high-quality, efficiently polished metal components will only grow, solidifying the place of automatic polishing machines as essential tools in the production process. Investing in such technology not only boosts productivity but also enhances the overall quality of manufactured goods, ultimately benefiting both producers and consumers alike.