The Evolution of the Famous Tube Mirror Polishing Machine

In the realm of optical components manufacturing, the tube mirror polishing machine has emerged as a pivotal technology for achieving high-precision finishes on cylindrical mirrors. This remarkable device has become a cornerstone in various industries, including astronomy, telecommunications, and laser technology. Its precision and efficiency have transformed the way mirrors are polished, contributing significantly to advances in optical performance.

The tube mirror polishing machine is designed specifically to handle the unique challenges associated with bending and shaping cylindrical substrates. Traditional polishing methods often fell short when it came to achieving the fine surface quality required for high-performance mirrors. However, the advent of specialized polishing machines allowed manufacturers to overcome these hurdles, ensuring that mirrors achieve the necessary flatness and surface roughness.

The Evolution of the Famous Tube Mirror Polishing Machine

Moreover, the innovative designs of these machines incorporate a combination of advanced abrasives and polishing pads tailored specifically for different types of materials. This versatility allows manufacturers to work with a wide range of substrates, including glass, ceramics, and various metal alloys. The ability to customize polishing parameters reduces production time and enhances the overall efficiency of the manufacturing process.

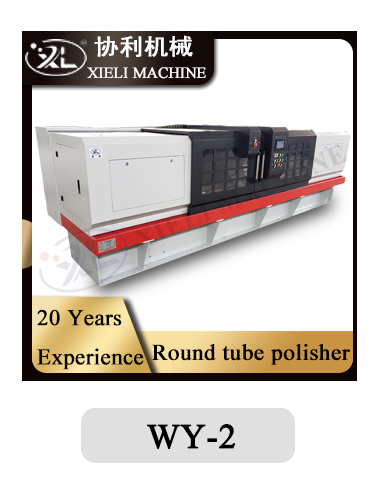

famous tube mirror polishing machine

In addition to their technical capabilities, tube mirror polishing machines are also designed with user-friendliness in mind. Many newer models feature intuitive interfaces, allowing operators to set parameters quickly and monitor the polishing process in real-time. This ease of use helps to minimize errors and enhances the skill level required for machine operation, making it accessible to a broader range of personnel.

The impact of these machines on the industry cannot be overstated. In astronomy, for example, the quality of mirrors directly influences the performance of telescopes. The precision provided by tube mirror polishing machines enables astronomers to make groundbreaking discoveries by enhancing image clarity and resolution. Similarly, in telecommunications, high-quality mirrors are essential for ensuring efficient signal transmission in fiber optics.

As technology continues to advance, the design and functionality of tube mirror polishing machines will only improve. Innovations in materials science, robotics, and artificial intelligence are expected to usher in a new era of precision manufacturing. This evolution will not only enhance the capabilities of the machines themselves but also open up new possibilities in various fields where optical performance is paramount.

In conclusion, the tube mirror polishing machine stands as a testament to the incredible advancements in manufacturing technology. Its role in producing high-quality optical components will undoubtedly continue to shape industries and foster innovation for years to come. As we look to the future, one thing remains clear the journey of precision in optical manufacturing is an ongoing endeavor, propelled by machines that redefine the standards of excellence.