Exploring the Export Landscape of Bryant Centerless Grinders

The manufacturing industry relies heavily on precision machining tools, and among these, centerless grinders hold a significant position. As industries increasingly demand higher efficiency and accuracy in producing components, companies specializing in centerless grinding machinery, like Bryant, have emerged as key players in global markets. This article examines the export landscape of Bryant centerless grinders, shedding light on their significance, application, and market dynamics.

Understanding Centerless Grinding Technology

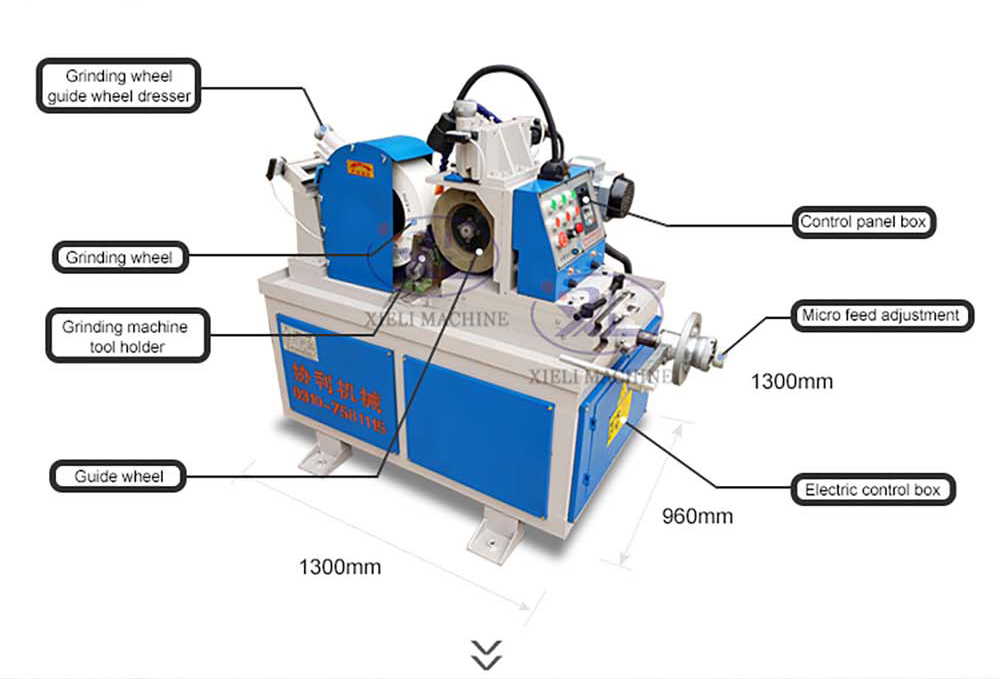

Centerless grinding is a method of removing material from a workpiece without the necessity of supporting it between centers. This process is particularly effective for producing small to medium-sized batches of parts, where high precision and repeatability are required. The machines operate on the principle of rotating the workpiece against a grinding wheel and a regulating wheel, allowing for an efficient removal of material. Bryant, known for its advanced engineering and innovative designs, has developed centerless grinders that offer superior performance, versatility, and reliability.

The Role of Export in Business Expansion

For manufacturers like Bryant, international markets represent a crucial avenue for growth. Exporting centerless grinders allows the company to tap into diverse markets, increasing their reach to customers who require quality machining solutions in various sectors including automotive, aerospace, medical, and more. The global demand for precision-engineered components continues to rise, making the export of specialized machinery not just beneficial but essential for maintaining competitive advantage.

Market Dynamics and Buyer Preferences

bryant centerless grinder exporters

The export market for centerless grinders is influenced by several factors, including technological advancements, economic conditions, and regional industry demands. Buyers in different regions may have distinct preferences based on their specific applications. For instance, manufacturers in the aerospace industry may prioritize precision and reliability over other factors, while those in automotive might focus on cost-efficiency and scalability. Understanding these varying needs allows exporters to tailor their offerings, ensuring they remain relevant in a competitive market.

Challenges in the Export Process

While exporting can be highly beneficial, it also presents challenges. Compliance with international regulations, tariffs, and logistics can complicate the process. Additionally, companies must navigate language barriers and cultural differences, which can impact negotiations and customer relationships. For Bryant, overcoming these challenges requires a combination of robust strategic planning, effective communication, and local market insights.

Conclusion

As industries continue to evolve and the demand for high-precision machinery grows, Bryant centerless grinders stand out as a vital resource for manufacturers worldwide. Their commitment to innovation and quality reinforces their position as a preferred choice in the export market. The ongoing expansion into international markets not only strengthens Bryant’s business portfolio but also contributes to advancements in manufacturing processes globally.

The landscape of Bryant centerless grinder exports illustrates a dynamic interplay between technology, market needs, and strategic growth initiatives. By understanding these elements, manufacturers can position themselves to thrive in an increasingly competitive global environment. As they navigate the complexities of exporting, they will continue to play a crucial role in the advancement of precision engineering and contribute to a more efficient manufacturing future.