The Monza 300 Centerless Grinder A Benchmark in Precision Engineering

In the realm of precision machining, the Monza 300 centerless grinder has carved a niche for itself as a benchmark for quality and efficiency. The factory that produces the Monza 300 stands as a testament to modern engineering, combining innovative technologies with traditional craftsmanship to deliver a machine that meets the rigorous demands of various industries.

Design and Functionality

The Monza 300 centerless grinder is designed to handle the complexities of grinding operations with ease. Its robust construction provides stability during operation, which is crucial for attaining the precise tolerances required in today’s manufacturing processes. The machine employs a unique feed system that significantly enhances its grinding capabilities, allowing for high-speed operations without compromising on accuracy.

One of the standout features of the Monza 300 is its versatility. This grinder is capable of processing a wide range of materials, from hard metals to softer plastics, making it suitable for industries such as automotive, aerospace, and medical equipment manufacturing. Its ability to switch between different grinding operations quickly and efficiently sets it apart from competitors in the market.

Advanced Technology

The factory producing the Monza 300 is equipped with state-of-the-art technology that plays a crucial role in the manufacturing process. Computer Numerical Control (CNC) integration allows for automated and precise adjustments, minimizing human error and ensuring consistency in output. The machining centers are also fitted with advanced monitoring systems that provide real-time feedback on performance, allowing operators to make immediate adjustments as necessary.

Moreover, the use of high-quality materials in construction enhances the longevity of the machine, ensuring it can withstand the rigors of continuous operation. The grinders also feature advanced cooling systems to manage heat generation during grinding, which, if unchecked, can lead to material distortion and reduced tool life.

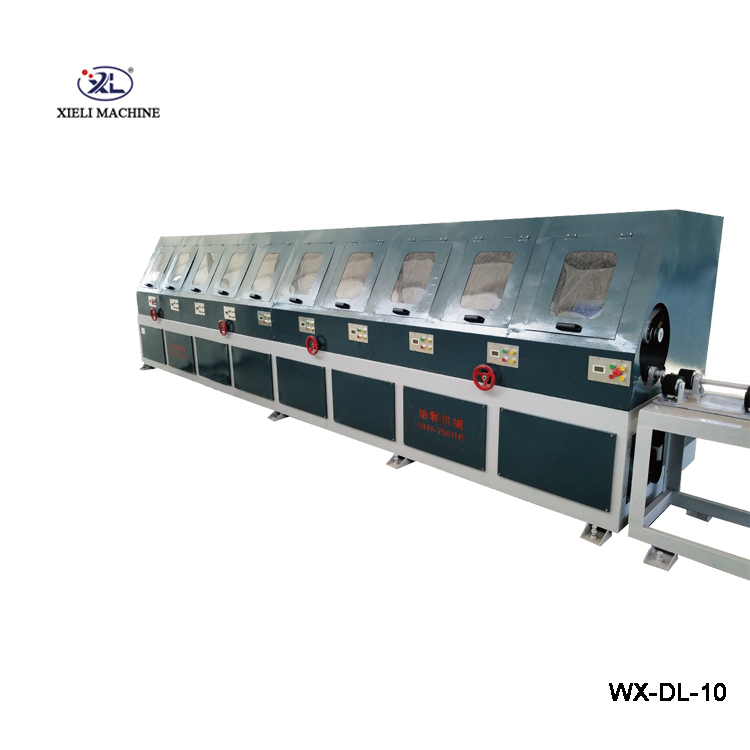

monza 300 centerless grinder factory

Commitment to Quality

Quality control is paramount in the manufacturing of the Monza 300. The factory employs rigorous testing protocols at every stage of production. From initial components to the final assembled machine, every part undergoes extensive evaluation to ensure it meets the strictest standards. This dedication to quality ensures that customers receive a reliable and high-performing machine that can operate efficiently for years.

Additionally, the factory invests in employee training and development, recognizing that skilled personnel are essential in maintaining high production standards. Continuous training programs keep workers abreast of the latest techniques and technologies, enhancing the overall efficiency and output quality of the factory.

Environmental Responsibility

In today’s industrial landscape, sustainability is more important than ever. The Monza 300 factory has embraced eco-friendly practices, implementing waste reduction initiatives and energy-efficient processes. By investing in green technologies, the factory not only minimizes its ecological footprint but also appeals to customers who are increasingly prioritizing sustainability in their supply chains.

Conclusion

The Monza 300 centerless grinder represents the pinnacle of modern manufacturing, embodying precision, versatility, and quality. The dedication showcased by its factory in design, technology, and sustainability has not only established Monza as a leader in the machining industry but has also set new standards for what can be achieved in grinding operations. Reliability and efficiency are at the core of its operation, making the Monza 300 an invaluable asset for any manufacturing process that demands the very best. As industries continue to evolve, the Monza 300 remains at the forefront, ready to meet the challenges of tomorrow’s manufacturing landscape.