The OEM Landis Viking Centerless Grinder A Revolution in Precision Grinding

In the world of manufacturing, precision is paramount. One of the notable advances in this area is the development of the OEM Landis Viking Centerless Grinder. This machine has become an essential tool for manufacturers who demand high accuracy, increased productivity, and reduced operational costs in their grinding processes.

What is Centerless Grinding?

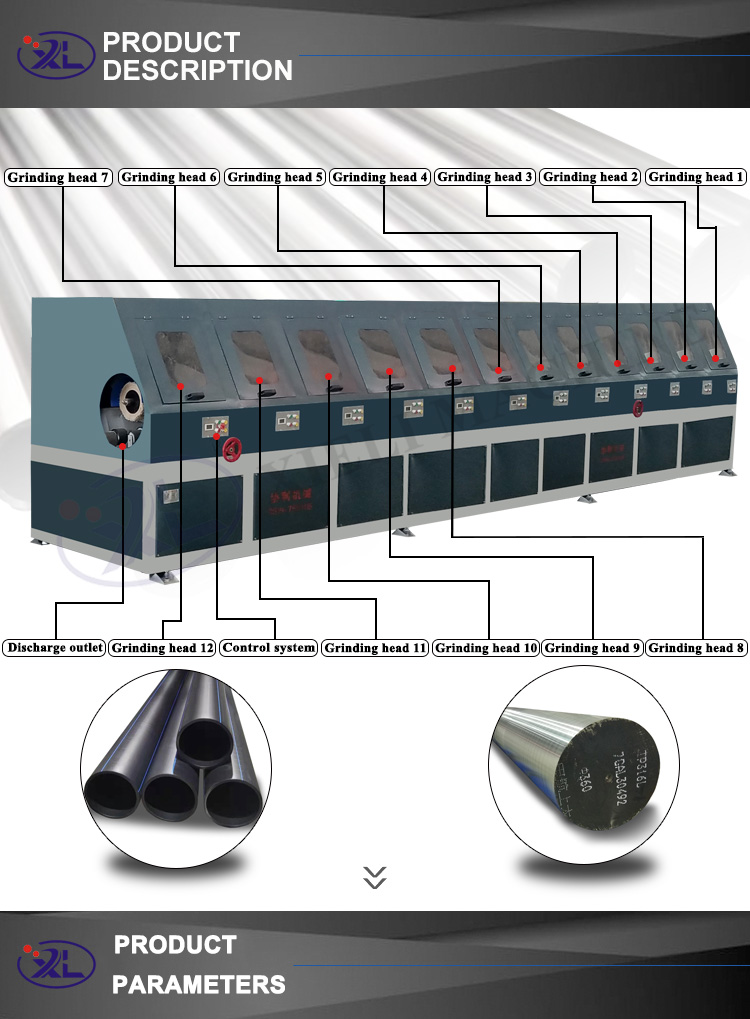

Centerless grinding is a machining process that allows for the grinding of cylindrical workpieces without the need for traditional centers to hold the workpiece in place. This methodology offers numerous advantages over conventional grinding techniques, including consistency in part dimensions and the ability to handle longer workpieces with minimal setup time. The Landis Viking Centerless Grinder exemplifies these advantages, providing manufacturers with a dynamic solution to tackle their grinding needs.

Features and Benefits of the OEM Landis Viking Centerless Grinder

1. Versatile Design The Landis Viking is designed to handle a wide range of part sizes and shapes, making it suitable for various industries, including automotive, aerospace, and medical. Its versatility allows for the grinding of multiple workpieces on a single machine, enhancing productivity.

2. Enhanced Precision One of the standout features of the Viking Centerless Grinder is its ability to achieve tight tolerances and surface finishes. The machine is engineered to minimize deviation during the grinding process, ensuring that each workpiece meets stringent specifications. This is critical in industries where precision is not just preferred, but required.

3. User-Friendly Interface The grinder comes equipped with an intuitive control system that simplifies operation and reduces the learning curve for new users. This user-friendly interface enables operators to make quick adjustments and monitor the grinding process in real-time, leading to greater operational efficiency.

oem landis viking centerless grinder

4. Robust Construction Built with high-quality materials, the OEM Landis Viking is designed to withstand the rigors of industrial use. Its robust construction minimizes vibrations during operation, which contributes to the longevity of both the machine and the workpieces being processed.

5. Automation Capabilities The integration of advanced automation features, such as automatic feeding and in-process gauging, allows manufacturers to streamline their operations further. Automation not only increases throughput but also reduces human error, resulting in improved product quality.

6. Cost-Effectiveness While the initial investment in a Landis Viking Centerless Grinder may be significant, the long-term savings associated with increased productivity, reduced scrap rates, and minimized downtime make it a cost-effective solution for manufacturers looking to optimize their grinding processes.

Applications of the Landis Viking Centerless Grinder

The versatility of the OEM Landis Viking makes it applicable in various sectors. In automotive manufacturing, it is commonly used for grinding camshafts and crankshafts, where precision is crucial. In the medical field, the grinder is employed to produce components like surgical instruments and implantable devices, which require both high precision and excellent surface finishes. Furthermore, it is increasingly being utilized in the production of electronic components, where precision is necessary for the functionality of devices.

Conclusion

The OEM Landis Viking Centerless Grinder represents a significant advancement in the field of machining. Its ability to deliver high precision, coupled with its robust design and advanced features, makes it an invaluable tool for manufacturers seeking to enhance their productivity and achieve superior product quality. As industries continue to evolve and demand higher standards, the Viking Centerless Grinder stands ready to meet these challenges head-on, solidifying its place as a critical asset in modern manufacturing processes.