Understanding Wholesale Centerless Grinder Tables

In the realm of precision machining, centerless grinders play a vital role in manufacturing and finishing processes. As industries continuously seek enhanced productivity and efficiency, wholesale centerless grinder tables have emerged as pivotal components in the innovative landscape of machining operations. This article delves into the importance, functionality, and benefits of these tables, underscoring their significance in achieving high-quality machining results.

What is a Centerless Grinder?

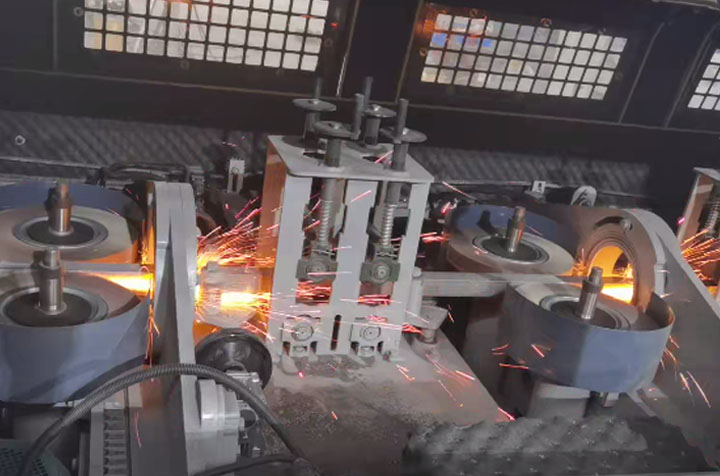

A centerless grinder is a type of grinding machine that enables precision grinding of workpieces without the need for centering the material. This machine operates on the principle of establishing a support system that compensates for the absence of centers, allowing for smooth and continuous grinding. Centerless grinding is particularly advantageous for processing cylindrical shapes, such as rods, tubes, and pins, making it a favored choice among manufacturers.

The Significance of Centerless Grinder Tables

At the heart of any efficient centerless grinding system lies the grinder table. This component is essential in providing stability and support to the workpieces during the grinding process. Wholesale centerless grinder tables play a critical role in maintaining the alignment and orientation of materials, ensuring that they are processed uniformly and accurately.

By integrating robust materials and advanced engineering designs, these tables contribute significantly to the overall effectiveness of the grinding operation. High-quality centerless grinder tables help to minimize vibrations and can withstand the forces exerted by the grinding wheels, enhancing the durability and longevity of the machinery.

Key Features of Wholesale Centerless Grinder Tables

1. Adjustability and Precision Many wholesale centerless grinder tables are designed with adjustable features to accommodate various sizes and shapes of workpieces. This flexibility allows manufacturers to refine their processes and adapt to different product specifications without compromising accuracy.

2. Material Composition The materials used in constructing these tables often include high-grade steel and alloys that resist wear and provide the necessary strength to endure prolonged grinding operations. This ensures that the tables maintain their shape and functionality over time.

wholesale centerless grinder tables

3. Surface Finish A smooth surface finish on the table is critical for reducing friction and enhancing the grinding process. Wholesale tables are typically manufactured with precision, featuring surface treatment processes that promote minimal resistance.

4. Customization Options Many suppliers offer customization services for centerless grinder tables, allowing manufacturers to tailor the specifications according to their unique operational requirements. This customization ensures optimal integration within existing systems and enhances overall productivity.

The Benefits of Using Wholesale Centerless Grinder Tables

Utilizing wholesale centerless grinder tables presents several advantages to manufacturers

- Cost-Effectiveness Purchasing tables in wholesale quantities often results in cost savings, enabling manufacturers to invest in quality components without exceeding their budgets.

- Enhanced Productivity By providing stability and precision, these tables can significantly reduce downtime and increase operational efficiency. Improved grinding performance translates into higher productivity levels for businesses.

- Quality Assurance Higher quality tables contribute to better finished products, resulting in fewer defects and reworks. This enhances the overall quality and reliability of the manufactured parts.

Conclusion

Wholesale centerless grinder tables are integral components in the machining industry, facilitating efficient and precise grinding processes. Their robust construction, adjustable features, and customizable options make them indispensable for manufacturers aiming to optimize their operations. As industries continue to evolve, investing in quality centerless grinder tables will remain a strategic move for businesses seeking to maintain a competitive edge in the market.