Wholesale Surface Grinder and Centerless Grinding An Overview

In the realm of precision machining and manufacturing, surface grinders and centerless grinders play pivotal roles. They are essential tools for producing high-quality, smooth surfaces on various materials, particularly metals. Understanding the importance of these machines can help manufacturers optimize their production processes and enhance the quality of their products.

What is a Surface Grinder?

A surface grinder is a machine tool used to provide a smooth finish on flat surfaces. It employs a rotating grinding wheel, which cuts metal away from the workpiece to achieve the desired surface finish and size. Surface grinders are critical in industries where precision is paramount, such as aerospace, automotive, and tool manufacturing.

In the wholesale market, surface grinders are available in various sizes and configurations, catering to different production needs. They can be manual or automatic, with features that allow for elevation adjustment, tilt, and precision feed. Industries looking to purchase in bulk can benefit from wholesale deals, ensuring they acquire quality machines without overspending, maximizing their return on investment.

Centerless Grinding An Indispensable Process

Centerless grinding is another critical process in the machining world. Unlike traditional grinding methods, where the workpiece is held between two centers, centerless grinding supports the workpiece on a work rest blade with the grinding wheel and a regulating wheel. This setup allows for high throughput and precision without the need for complex setups.

wholesale surface grinder centerless

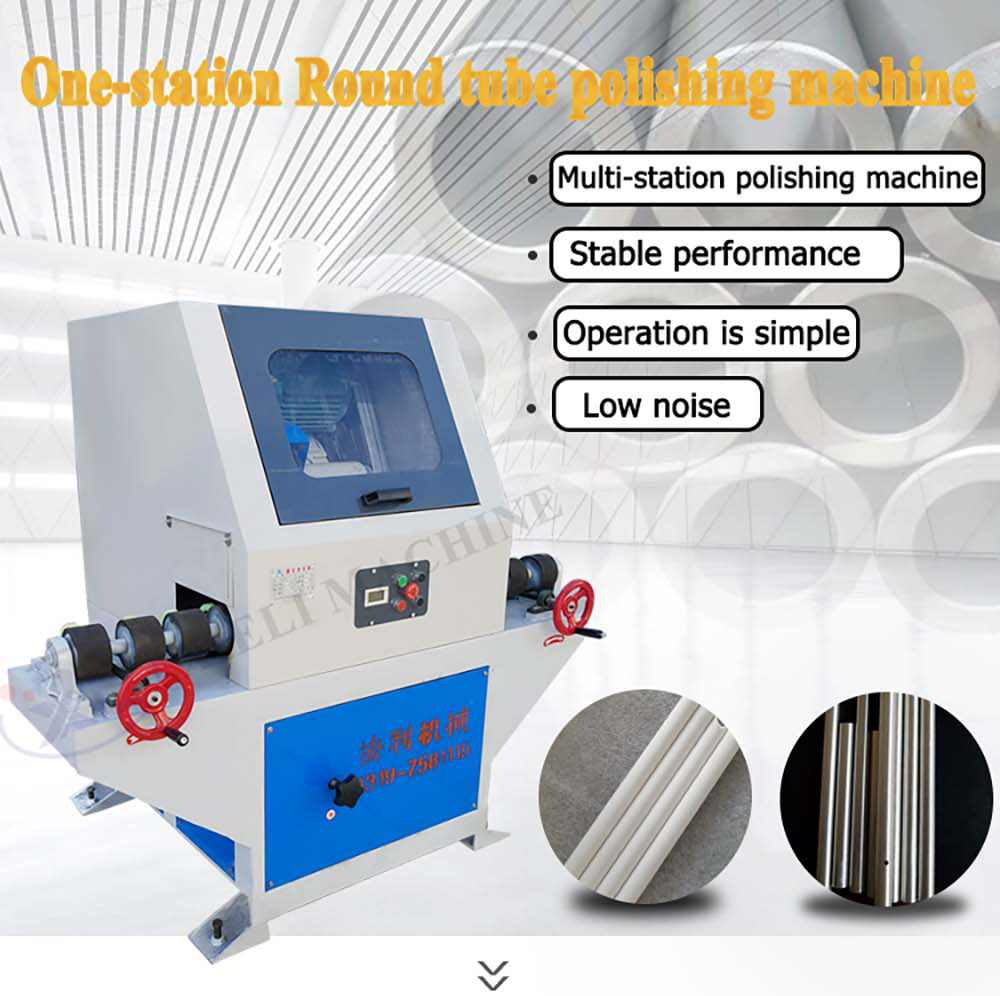

This type of grinding is particularly beneficial for producing cylindrical shapes in a continuous process. It's commonly used for manufacturing rods, shafts, and tubes in various industries, allowing for consistent diameters and quality finishes. The ability to produce high volumes with minimal downtime makes centerless grinding a preferred choice for many manufacturers.

The Importance of Wholesale Purchase

For companies looking to enhance their manufacturing capabilities, purchasing surface grinders and centerless grinders wholesale can be a strategic move. Wholesale purchasing not only offers significant cost advantages but also allows for better negotiating power with suppliers. By acquiring multiple machines at a time, businesses can often secure better warranties, service agreements, and support, creating a more favorable long-term investment.

Additionally, many suppliers offer comprehensive after-sales support for machines purchased in bulk. This support is crucial, as it ensures that any issues with the machines can be promptly addressed, minimizing production downtime. Furthermore, having a reliable network of suppliers through wholesale purchasing builds a foundation for long-term business relationships that can yield additional benefits, such as access to the latest technology and upgrades.

Conclusion

In conclusion, surface grinders and centerless grinding machines are vital tools in modern manufacturing. Their ability to produce high-quality finishes and maintain tight tolerances makes them essential for many industries. For businesses seeking to improve their production capabilities, considering wholesale purchasing of these machines can lead to significant savings and enhanced operational efficiency.

As the demand for high precision and quality continues to rise in the global market, investing in reliable and advanced grinding technology will undoubtedly pay dividends. Whether upgrading existing equipment or expanding manufacturing capabilities, businesses should prioritize securing high-quality surface and centerless grinders through wholesale channels to fuel their growth and success in an increasingly competitive landscape.