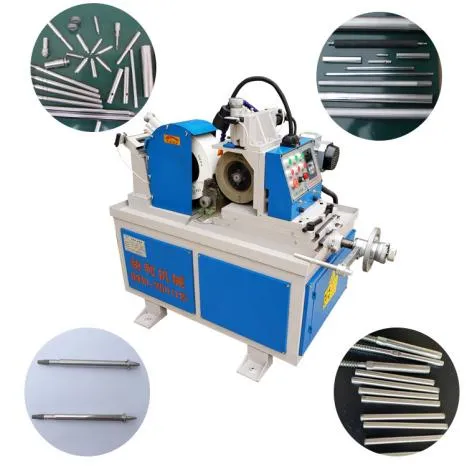

Understanding Centerless Grinding Machine Parts A Comprehensive Overview

Centerless grinding is a precision machining process that allows for the efficient grinding of cylindrical parts without the need for a central axis. This method stands out in manufacturing due to its ability to produce high-precision components at an accelerated pace. However, the success of centerless grinding hinges significantly on the various parts that comprise the grinding machine.

Key Components of Centerless Grinding Machines

1. Grinding Wheel The grinding wheel is the heart of the centerless grinding machine. It is responsible for removing material from the workpiece. Made of abrasive materials, the grinding wheel is specifically designed for the task and can vary in size and grit depending on the required finish and tolerance levels. The selection of the appropriate grinding wheel is vital, as it impacts the efficiency and quality of the grind.

2. Regulating Wheel Positioned opposite to the grinding wheel, the regulating wheel serves two primary functions it controls the rotational speed of the workpiece and assists in feeding it through the grinding area. By adjusting the angle and pressure of the regulating wheel, operators can manipulate the speed of the workpiece as it moves between the wheels.

3. Work Rest Blade This component supports the workpiece and ensures that it is held in place during the grinding process. The work rest blade's position can be adjusted to accommodate different diameters of workpieces, providing versatility to the machine. Proper alignment of this blade is essential to maintain parallelism and achieve the desired dimensions.

4. Bed The bed of the centerless grinding machine provides a stable base for all the other components. A robust bed design minimizes vibrations and ensures that the machine maintains its alignment over time. The rigidity of the bed contributes to the overall accuracy of the grinding operation.

centerless grinding machine parts quotes

5. Control System Modern centerless grinding machines are often equipped with advanced control systems that allow operators to monitor and adjust the machine's parameters in real-time. These systems enhance precision, facilitate automation, and can even integrate with other manufacturing processes for greater efficiency.

6. Coolant System Given the heat generated during grinding, a coolant system is crucial for maintaining optimal temperatures. Coolants help to reduce wear on the grinding wheel, prolonging its life and ensuring better performance. Additionally, effective cooling prevents thermal deformation of the workpiece, enhancing the quality of the final product.

Importance of Proper Maintenance

To maximize the performance and longevity of centerless grinding machines, regular maintenance of the components is essential. This includes checking the alignment of the grinding and regulating wheels, ensuring the work rest blade is correctly positioned, and monitoring the condition of the coolant. Regular inspections and maintenance not only enhance the machine's efficiency but also prevent costly downtime.

Conclusion

Centerless grinding machines play a pivotal role in the manufacturing industry, providing efficient solutions for precision machining. Understanding the various parts of these machines—such as the grinding wheel, regulating wheel, work rest blade, bed, control system, and coolant system—enables manufacturers to optimize their processes and achieve higher levels of accuracy and productivity. As technology continues to advance, the integration of innovative components and control systems will further enhance the capabilities of centerless grinding machines, solidifying their place in modern manufacturing.