The Importance of Buying Centerless Grinder Blades Enhancing Efficiency and Precision in Manufacturing

In the manufacturing industry, precision and efficiency are paramount. One of the essential tools that contribute to achieving these goals is the centerless grinder. This machine is favored for its ability to produce highly refined finishes and maintain precise tolerances on round workpieces. At the heart of centerless grinding operations are the grinder blades, which play a pivotal role in the grinding process. Thus, understanding the significance of purchasing quality centerless grinder blades is crucial for any manufacturing operation aiming to optimize productivity and output quality.

What are Centerless Grinder Blades?

Centerless grinder blades, often referred to as grinding wheels or blades, are crucial components of a centerless grinding machine. They help in the removal of material from the workpiece without the need for a fixed reference point, which is the essence of centerless grinding. The blades can be made from various materials, including aluminum oxide, silicon carbide, and CBN (cubic boron nitride), each suited for specific applications and material types.

Why Quality Matters

The quality of the grinder blades directly influences the performance of the centerless grinding process. High-quality blades can ensure

1. Improved Finish Quality Quality blades provide a finer finish, reducing the need for secondary operations and improving the aesthetic and functional quality of the final product.

2. Increased Longevity Investing in durable blades means fewer replacements, leading to reduced downtime and maintenance costs. High-quality materials withstand wear and tear better than cheaper alternatives.

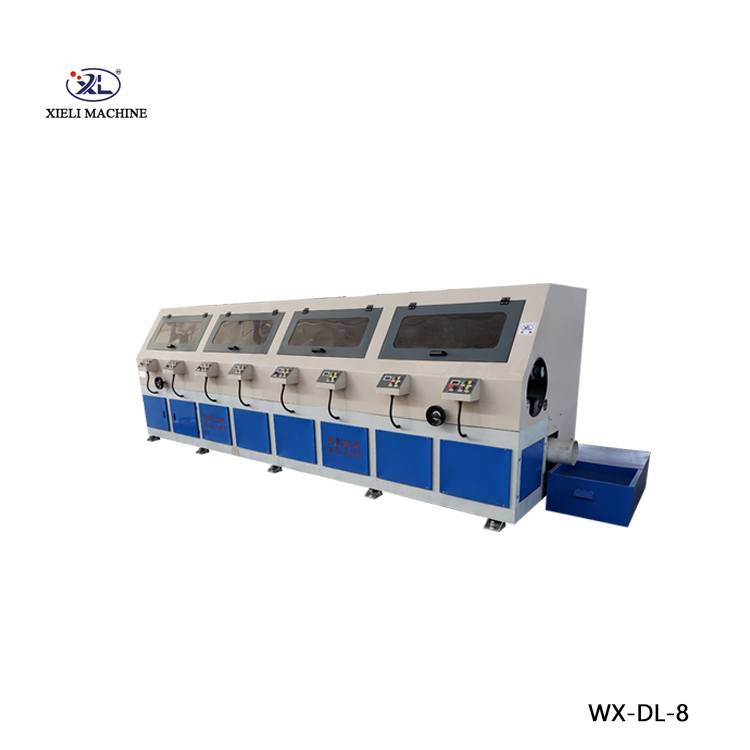

buy centerless grinder blades

4. Efficiency in Production Better blades facilitate quicker material removal rates, leading to shorter cycle times and increased throughput – a vital factor in meeting production targets and customer demands.

Factors to Consider When Buying Centerless Grinder Blades

1. Material Type Depending on the materials being machined, the type of blade material should be carefully selected. For instance, CBN wheels are preferred for hardened steel, while ceramic options excel in tough materials.

2. Grit Size The grit size of the blade determines the finish quality and removal rate. Coarser grits are suitable for heavy material removal, while finer grits achieve a smoother finish.

3. Bond Type The bond holds the abrasive grains together; choosing the right bond type (like resin, vitrified, or metal) can significantly impact the blade's performance in different applications.

4. Dimensions Ensure the blades you purchase match the specifications of your centerless grinding machine in terms of diameter, thickness, and hole size.

5. Supplier Reputation Always source from reputable suppliers who can provide detailed product specifications and post-purchase support, ensuring that you receive reliable and effective products.

Conclusion

In conclusion, buying the right centerless grinder blades is a crucial decision for manufacturers who desire to enhance their machining processes. Investing in high-quality blades can lead to superior finish quality, increased tool life, and enhanced overall efficiency. It is essential to consider factors such as material type, grit size, bond type, and supplier reputation to make informed purchasing decisions. By prioritizing these elements, manufacturers can not only achieve optimal performance from their centerless grinding machines but also strengthen their competitive edge in an increasingly demanding market.