The Rise of Centerless Grinders A Buying Guide

In the world of precision machining, centerless grinders have emerged as essential tools for achieving high levels of accuracy and efficiency. These machines are integral in various industries, including automotive, aerospace, and tool manufacturing, where the need for precise dimensions and smooth finishes is paramount. With this growing demand, many operators are now considering purchasing a centerless grinder for sale. This article discusses the benefits of these machines, what to consider when buying one, and where to find the best options on the market.

Understanding Centerless Grinding

Centerless grinding is a manufacturing process that utilizes a rotating grinding wheel and a regulating wheel to grind cylindrical parts without having to align them with a spindle. This process allows for continuous production and is highly efficient for processing large quantities of parts. The primary advantage of centerless grinding is its ability to maintain tight tolerances while reducing cycle times, making it ideal for high-volume applications.

Benefits of Centerless Grinders

1. Efficiency Centerless grinders can operate continuously, which significantly increases production rates. They are designed for automatic loading and unloading systems, which further enhances their efficiency.

2. Precision These machines provide highly accurate results, often achieving tolerances within a few microns. This level of precision is crucial for industries that require exact specifications.

3. Versatility Centerless grinders can handle a variety of applications, from grinding simple rods to complex parts. They are capable of working with different materials, including steel, aluminum, and plastics.

4. Cost-Effective When considering the time saved on setup, labor costs, and the ability to produce higher quantities of parts, centerless grinders can be a cost-effective solution in the long run.

What to Consider When Buying a Centerless Grinder

When searching for a centerless grinder for sale, it is essential to take several factors into account to ensure you are making a wise investment

buy engine centerless grinder for sale

1. Type of Machine There are various types of centerless grinders, including in-feed and through-feed grinders. Understanding the specific needs of your operations will help determine which type is right for you.

2. Size and Capacity Consider the size of the parts you need to grind and the machine's capacity. Ensure that the grinder you choose can handle the dimensions and weights of the materials you will be processing.

3. Production Volume Think about your production requirements. A more robust machine may be necessary for high-volume applications, while a smaller, less expensive model may suffice for lower volumes.

4. Technology and Features Modern centerless grinders come with advanced technology such as CNC controls, which can enhance precision and ease of use. Evaluate the features that will benefit your operations the most.

5. Budget Centerless grinders can range significantly in price based on size, capacity, and features. Determine your budget beforehand to help narrow down your options.

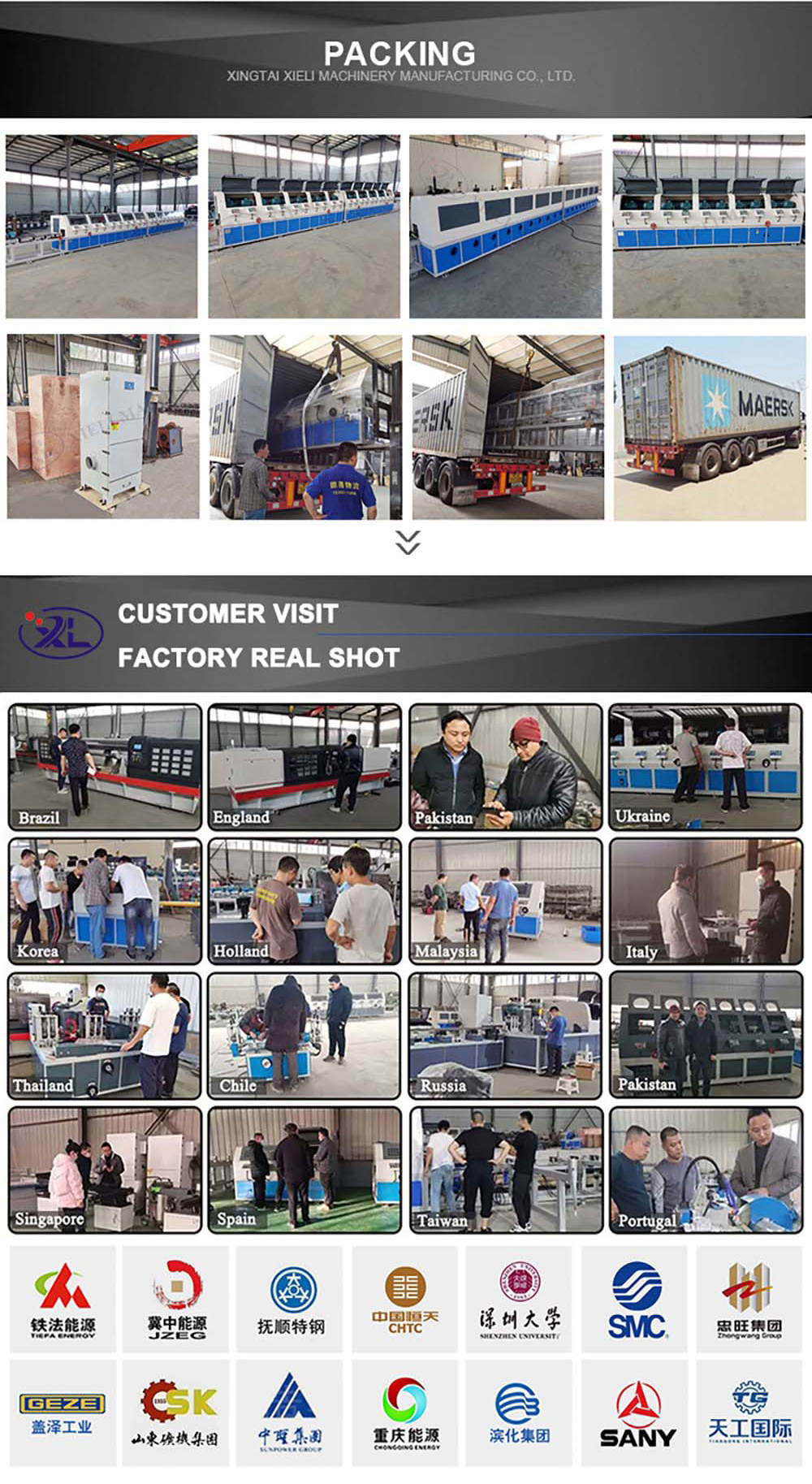

6. Supplier Reputation Research the suppliers and manufacturers of centerless grinders. Look for reviews, request referrals, and check their service and support options to ensure reliability and quality.

Where to Buy Centerless Grinders

When it comes to sourcing a centerless grinder for sale, there are several avenues to explore

- Manufacturers Purchasing directly from manufacturers can often provide the best warranties and service options. - Industrial Equipment Suppliers Many suppliers specialize in selling new and refurbished grinding machines. - Online Marketplaces Websites such as eBay, Amazon, or specialized industrial equipment sites often feature a variety of options, both new and used. - Trade Shows Attending trade shows can help you see machines in action and interact with suppliers directly.

In conclusion, investing in a centerless grinder can significantly enhance your machining operations. By understanding the benefits, considering the essential factors, and exploring various purchasing avenues, you can find the perfect centerless grinder that meets your needs and budget. Whether you are looking for a new or used machine, doing thorough research will ensure that you make an informed decision that will pay off in increased efficiency and precision.