The Rise of OEM Pipe Rust Remover Machines A Comprehensive Overview

In today’s industrial landscape, the durability and longevity of equipment are paramount. Rust, a relentless adversary of metal structures, poses significant challenges, especially in industries reliant on pipeline systems. This is where the innovation of OEM (Original Equipment Manufacturer) pipe rust remover machines comes into play, offering effective solutions for rust prevention and removal.

Understanding Rust and Its Implications

Rust forms when iron or its alloys react with oxygen and moisture in the environment, leading to oxidation. This process not only undermines the structural integrity of pipes but can also lead to costly repairs, system failures, and safety hazards. In industries such as oil and gas, water treatment, and manufacturing, rust can severely impede operations. Therefore, maintaining clean and rust-free pipes is essential for ensuring the efficiency and safety of industrial operations.

The Functionality of OEM Pipe Rust Remover Machines

OEM pipe rust remover machines are specialized devices designed to clean pipelines effectively by removing rust through various methods, including mechanical abrasion, chemical treatments, or even advanced technologies like ultrasound. These machines are built to cater to the unique specifications and requirements of different industries, ensuring that they can handle a variety of pipe sizes and materials.

One common technique employed by these machines is shot blasting, which involves propelling abrasive materials against the rusted surface. This mechanical method is highly effective at stripping away rust while preserving the underlying metal. Another approach includes the use of chemical rust removers, which penetrate and dissolve rust without causing damage to the pipe itself.

Advantages of Using OEM Machines

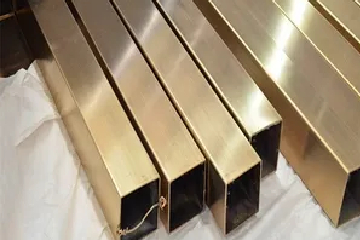

oem pipe rust remover machine

1. Customization OEM machines can be tailored to meet the specific needs of different industries and applications. Manufacturers can design machines that accommodate various pipe diameters, lengths, and materials.

3. Cost-Effectiveness By prolonging the lifespan of pipes and reducing downtime, OEM pipe rust remover machines can result in significant cost savings for companies. Regular maintenance using these machines can prevent extensive rust damage, leading to fewer replacements and repairs.

4. Environmentally Friendly Options Many OEM manufacturers are now focusing on eco-friendly solutions. Modern rust remover machines often utilize biodegradable chemicals and energy-efficient processes, minimizing their environmental impact.

Future Trends

As industries continue to evolve, the demand for more advanced and efficient rust removal technologies is likely to increase. Future innovations may include automation through robotics, artificial intelligence for predictive maintenance, and enhanced data analytics to monitor the condition of pipes in real time. Incorporating these technologies can further improve the effectiveness of OEM pipe rust remover machines, making them indispensable in industrial operations.

Conclusion

In conclusion, OEM pipe rust remover machines play a critical role in maintaining the integrity and efficiency of pipeline systems across various industries. By addressing the rust problem with specialized and innovative solutions, these machines not only contribute to the longevity of infrastructure but also enhance safety and operational efficiency. As technology continues to advance, the future of rust removal will likely see even more effective and eco-friendly solutions, solidifying the importance of these machines in modern industry.