The Role and Responsibilities of Centerless Grinder Operators in Factories

Centerless grinding, a precision machining process, is a critical operation in many manufacturing settings, particularly in factories that produce small to medium-sized parts for various industries. Centerless grinder operators play a vital role in ensuring that this operation runs smoothly, efficiently, and safely. Their expertise not only contributes to the quality of the finished products but also impacts the overall productivity of the manufacturing process.

Centerless grinding differs from traditional grinding methods by allowing the workpiece to be held in place without the need for a fixed central axis. This unique process enables continuous production, as multiple parts can be processed simultaneously, enhancing efficiency. However, this requires skilled operators who can manage the intricacies of the machinery and maintain strict tolerances.

The Role and Responsibilities of Centerless Grinder Operators in Factories

Once the machine is set up, the operator must monitor the grinding process closely. This includes feeding the workpieces into the machine, adjusting the speed and feed rates, and observing the grinding action. Operators utilize various measuring instruments such as calipers and micrometers to check dimensions and ensure that the parts meet the required specifications. If issues arise, operators must troubleshoot problems, which can range from machine malfunctions to inconsistencies in product quality.

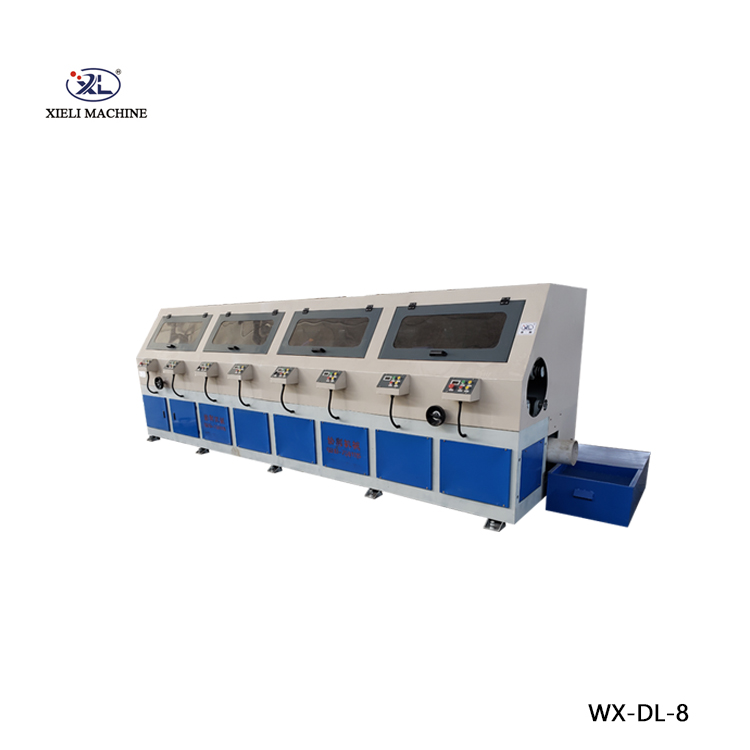

centerless grinder operator factories

In addition to machine operation and quality control, centerless grinder operators are also responsible for conducting routine maintenance on the grinding machines. Regular maintenance is essential to prevent breakdowns and extend the life of the equipment. This can include cleaning, lubricating moving parts, and replacing worn components. Operators must be knowledgeable about the specific machines they work with, often needing to conduct minor repairs themselves or coordinate with maintenance personnel for more complex issues.

Safety is another critical aspect of a centerless grinder operator's responsibilities. Operators must adhere to safety protocols and regulations to minimize the risk of accidents and injuries. This includes wearing appropriate personal protective equipment (PPE), understanding the machinery’s safety features, and maintaining a clean and organized workspace. Training in safety procedures is an ongoing process, ensuring that operators remain aware of potential hazards associated with grinding operations.

In modern manufacturing, the demand for high-quality precision parts is ever-increasing. As a result, the role of centerless grinder operators is becoming increasingly complex and specialized. Continuous advancements in technology, such as automation and CNC (computer numerical control) machinery, are changing the landscape of manufacturing. Operators must stay abreast of the latest trends and technologies, enhancing their skills to remain competitive in the industry.

In conclusion, centerless grinder operators are integral to the manufacturing process, responsible for setting up, monitoring, and maintaining grinding machines. Their expertise ensures the production of high-quality parts and contributes to the overall efficiency of factory operations. As technology evolves, so too does the need for skilled operators who can adapt to new challenges and innovations, making their role more crucial than ever in the manufacturing landscape.