Exploring the World of Ecotech Centerless Grinder Suppliers

In the realm of precision machining, the quality of grinding equipment is paramount for ensuring optimal performance and final product excellence. Among the various types of grinding machines, centerless grinders stand out for their ability to provide high precision and efficient, continuous operation. As industries demand tighter tolerances and improved production rates, the role of reliable centerless grinder suppliers, such as Ecotech, becomes increasingly significant.

What is a Centerless Grinder?

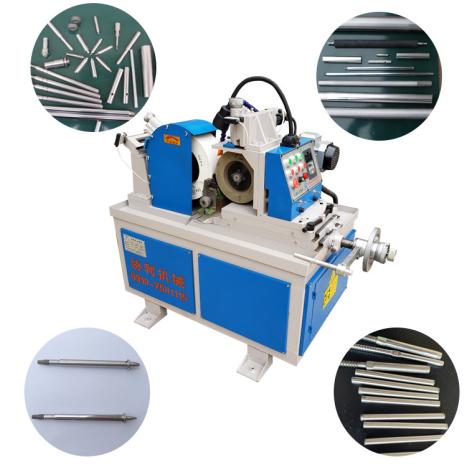

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding, where the workpiece is held between centers, a centerless grinder uses two wheels a grinding wheel and a regulating wheel. This unique setup allows for continuous feed of the workpiece, enabling high volume production without the need for complex setups. Centerless grinders are particularly favored in applications involving cylindrical parts such as shafts, pins, and tubes.

Ecotech A Leader in Centerless Grinding Solutions

Ecotech is recognized as a prominent supplier in the field of centerless grinding machinery. Their commitment to quality and innovation positions them as a go-to choice for manufacturers seeking advanced grinding solutions. With decades of experience in the industry, Ecotech offers a comprehensive range of centerless grinders that cater to diverse needs—from small, precision components to larger industrial applications.

One of Ecotech’s key strengths is its ability to provide customized solutions. Understanding that different industries have unique requirements, Ecotech engineers work closely with clients to devise grinding solutions that meet specific operational challenges. This tailored approach not only enhances productivity but also ensures a higher degree of accuracy and efficiency.

ecotech centerless grinder supplier

Product Range and Features

Ecotech’s lineup of centerless grinders includes models that can handle both infeed and thrufeed grinding processes. The choice between these methods often depends on the shape and size of the workpiece. For instance, infeed grinding is ideal for components with complex geometries, while thrufeed grinding excels in high-volume production of simpler, cylindrical parts.

Key features of Ecotech’s centerless grinders include precision-engineered components, advanced CNC controls, and innovative cooling systems. These features contribute to extended machine life and consistent performance, making them suitable for various materials, including metals and plastics. Moreover, with user-friendly interfaces, operators can quickly adjust settings to adapt to changing production needs.

The Importance of Reliable Suppliers

Choosing the right centerless grinder supplier is crucial for maintaining seamless operations. A reliable supplier not only provides high-quality machinery but also offers ongoing support, maintenance services, and access to spare parts. Ecotech’s commitment to customer satisfaction is exemplified by its extensive after-sales support, ensuring that clients can quickly resolve any issues that arise during production.

In conclusion, as industries evolve and the demand for precision manufacturing continues to grow, the importance of high-quality centerless grinding machines and reliable suppliers like Ecotech cannot be overstated. By investing in advanced grinding solutions, manufacturers can enhance their productivity, ensure superior quality in their products, and ultimately gain a competitive edge in the market. Whether you are a small shop or a large manufacturing facility, partnering with a trusted centerless grinder supplier like Ecotech is an investment in efficiency and excellence.