Understanding Discount Surface Polishing Machines A Comprehensive Guide

In the world of manufacturing and fabrication, surface finishing plays an essential role in determining the final quality and appearance of a product. Among the various methods employed in surface finishing, polishing is one of the most crucial processes. It not only enhances the aesthetic appeal of products but also improves their lifespan and performance. With the rising demand for high-quality finished products, businesses are constantly on the lookout for efficient and cost-effective solutions. This is where discount surface polishing machines come into play.

What is a Surface Polishing Machine?

A surface polishing machine is a specialized piece of equipment designed to refine the surface of materials such as metals, plastics, and ceramics. These machines use various techniques and tools to remove imperfections, scratches, and oxidation, resulting in a smooth and shiny finish. Surface polishing can be achieved using different methods, including mechanical polishing, chemical polishing, and electro-polishing.

Mechanical polishing involves the use of abrasive materials to grind away the surface layer, while chemical polishing uses chemical agents to dissolve imperfections. Electro-polishing, on the other hand, utilizes an electric current to remove layers from the surface, leading to a high-quality finish.

Why Choose Discount Surface Polishing Machines?

1. Cost-Effectiveness As the name suggests, discount surface polishing machines are typically more affordable than their standard counterparts. This makes them an attractive option for small to medium-sized enterprises that may not have the budget for high-end equipment. By investing in a discount model, companies can achieve high-quality polishing results without breaking the bank.

2. Quality and Performance Contrary to common belief, discount machines do not necessarily compromise on quality. Many manufacturers produce discount models that offer similar features and performance levels as more expensive options. By researching and selecting reputable brands, businesses can find reliable machines that deliver excellent results.

3. Versatility Discount surface polishing machines come in various shapes and sizes, catering to different materials and finishing requirements. Whether you need a machine for polishing metal surfaces or delicate ceramics, there is likely a discounted model that fits your specific needs. This versatility allows businesses to handle a wide range of projects efficiently.

4. Accessibility The availability of discount surface polishing machines has increased due to the rise of online marketplaces and specialty equipment suppliers. This accessibility enables businesses to compare prices, read reviews, and make informed purchasing decisions. It also opens up opportunities for direct purchasing from manufacturers, often at reduced costs.

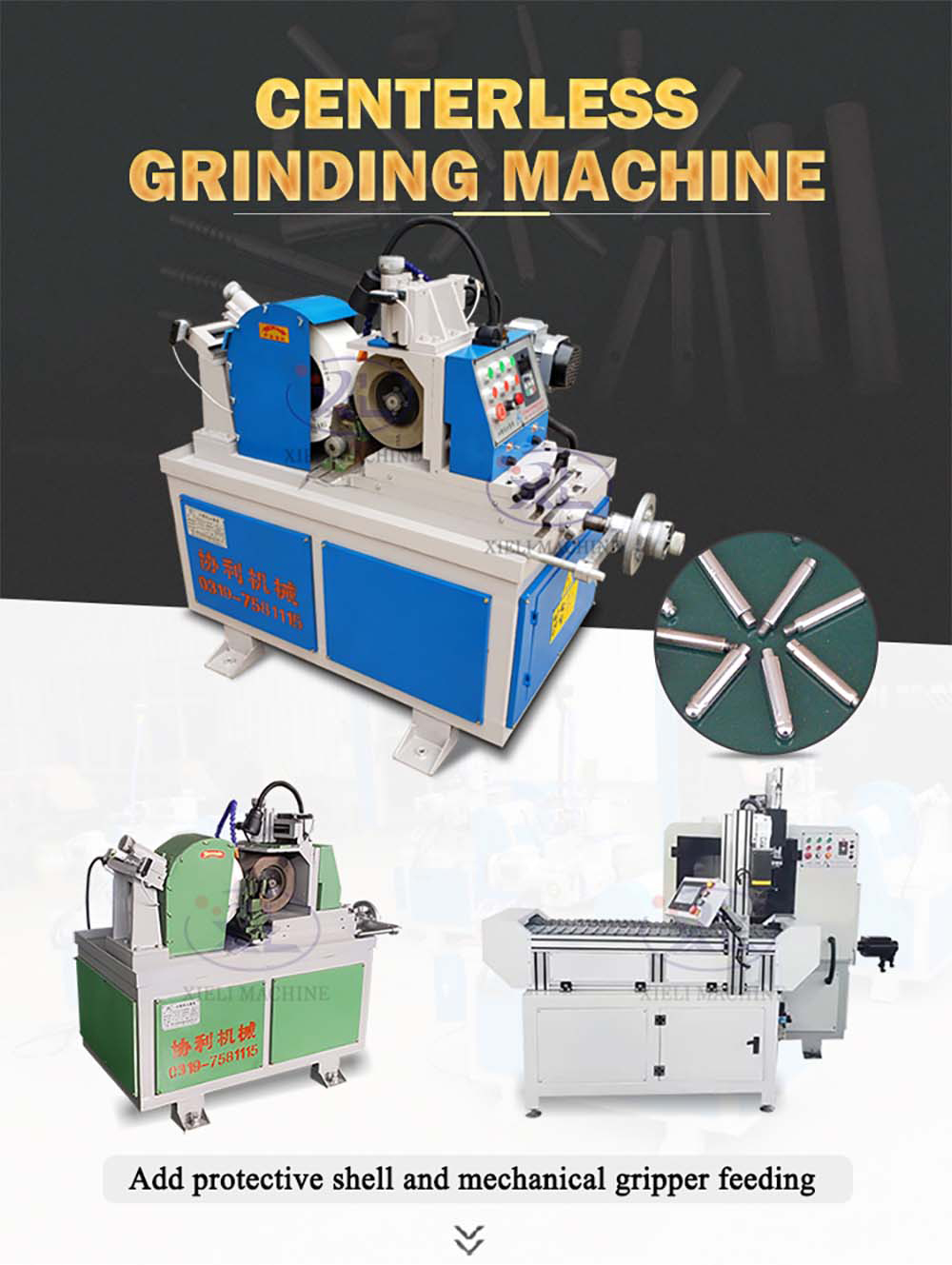

discount surface polishing machine

5. Ease of Use Many modern polishing machines are designed with user-friendliness in mind. Discount models often incorporate intuitive controls, making it easier for operators to achieve the desired finish with minimal training. This ease of use can lead to increased productivity and reduced labor costs.

Factors to Consider When Purchasing Discount Surface Polishing Machines

While the allure of discounts is undeniable, it is essential to consider several factors before making a purchase

1. Specifications Ensure that the machine's specifications meet the requirements of your projects. Check for compatibility with the materials you will be polishing and the level of finish you need.

2. Brand Reputation Research the manufacturer and read customer reviews. A reputable brand often provides better warranties and customer support.

3. Maintenance Requirements Understand the maintenance needs of the machine. Some discount models may require more frequent servicing, impacting overall costs in the long run.

4. Warranty and Support Look for machines that come with warranties. Having a reliable support system in place can save you time and money in case of any issues.

5. Training Needs Consider whether your team will need training to operate the machine. Investing in training can lead to better results and increased safety.

Conclusion

Discount surface polishing machines represent an excellent opportunity for businesses to achieve high-quality finishes without the hefty price tag. By understanding the types of machines available and considering essential factors during the purchasing process, companies can find the right equipment to enhance their production capabilities. In today's competitive market, investing in the right tools is crucial for maintaining quality and meeting customer expectations. Whether you're polishing large metal components or delicate ceramic items, the right discount surface polishing machine can make all the difference in your manufacturing process.