The Importance of Inner Polishing in Pipe Manufacturing A Focus on Discount Pipe Inside Polishing Machines

In the world of manufacturing, particularly in industries where precision and quality are paramount, the processes employed to enhance the physical characteristics of products can significantly impact the final output. One such process is the inner polishing of pipes, which is commonly performed using specialized machines. This article delves into the importance of inner polishing machines for pipes and the advantages of acquiring machines that provide discount rates without compromising quality.

The Role of Inner Polishing in Pipe Production

Inner polishing is an essential step in the production of pipes, especially in sectors like automotive, aerospace, chemical processing, and food and beverage. The primary objective of this process is to create a smooth inner surface, reducing friction and preventing the build-up of contaminants that can affect the flow of liquids or gases. Furthermore, a polished interior minimizes the risk of corrosion and enhances the overall longevity of the pipes.

Smooth interiors not only facilitate the efficient flow of materials but also significantly reduce the risk of blockages or failures that could lead to safety hazards. In applications involving high-pressure systems, where the integrity of the piping is crucial, the smoothness provided by inner polishing can prevent operational disruptions and costly downtimes.

Advantages of Discount Pipe Inside Polishing Machines

The market for pipe manufacturing equipment has seen a rise in the availability of inner polishing machines offered at discounted rates

. Opting for these machines can provide several benefits that make them an attractive choice for manufacturers without sacrificing the quality of the output.1. Cost Efficiency The primary advantage of discount machines is their affordability. Manufacturers often operate within tight budgets, and investing in high-quality yet reasonably priced machines can enhance profit margins. Purchasing a discount pipe inside polishing machine enables businesses to allocate resources to other crucial areas without compromising on production quality.

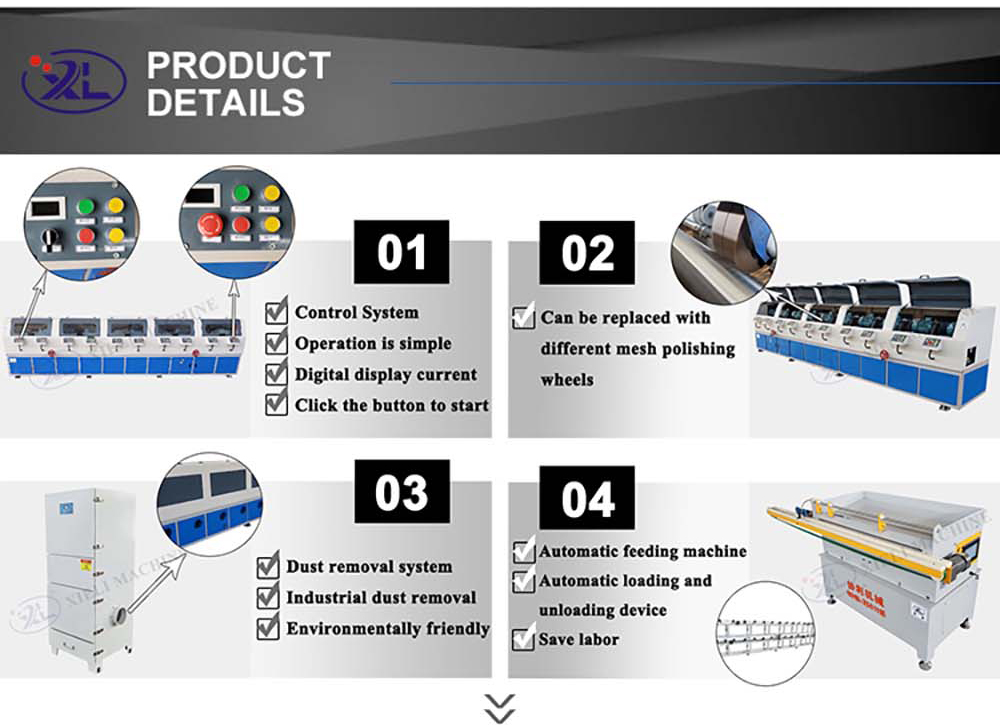

discount pipe inside polishing machine

2. Technology and Innovation Many manufacturers offering discounted machines ensure that their products incorporate the latest technology. This means that even at a lower price point, businesses can benefit from advancements in design and efficiency. Modern machines often utilize improved polishing techniques and materials that enhance performance and durability.

3. Quality Assurance Purchasing a discount machine does not mean settling for lower quality. Many reputable manufacturers provide warranties and customer support that ensure the machinery will perform as promised. By conducting proper due diligence and researching the manufacturer's reputation, businesses can secure high-quality machines at discounted prices.

4. Flexibility in Production With cost-effective inner polishing machines, manufacturers gain the ability to increase their production capacity without heavily investing in equipment. This flexibility can be particularly beneficial in meeting fluctuating demand within various markets, allowing for quicker turnaround times and improved customer satisfaction.

5. Sustainability Practices In an increasingly eco-conscious market, optimizing manufacturing processes through the use of efficient polishing machines can lead to reduced waste and energy consumption. Many discount machines are designed to operate with minimal environmental impact, which can also enhance a company's reputation as a responsible manufacturer.

Conclusion

The significance of inner polishing in pipe manufacturing cannot be overstated. A smooth inner surface not only enhances functionality but ensures the longevity and reliability of pipes under various conditions. Discount pipe inside polishing machines present a valuable opportunity for manufacturers looking to optimize their production processes while staying within budget.

By investing in such equipment, businesses can achieve high standards of quality and performance, ultimately leading to increased customer satisfaction and competitive advantage in the market. As the industry continues to evolve, embracing innovative approaches, including the adoption of cost-effective machinery, will be crucial for sustaining growth and meeting the needs of an ever-changing landscape. Whether for small-scale operations or large manufacturing units, discount inner polishing machines represent a strategic choice that aligns innovation with economic viability.