Understanding Discount Mini Centerless Grinders A Comprehensive Guide

In the world of precision machining, mini centerless grinders have carved out a niche for themselves due to their ability to produce high-quality, cylindrical parts efficiently and accurately. Especially in smaller workshops or for small batch production, these machines offer an economical solution without sacrificing performance. As manufacturing processes evolve and demand for precision increases, the question of affordability often arises. Enter the discount mini centerless grinder—an attractive option for many businesses looking to maximize productivity while minimizing costs.

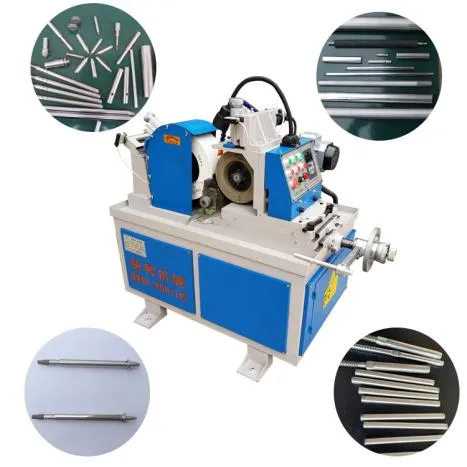

What is a Mini Centerless Grinder?

A mini centerless grinder is a specialized machine designed to refine the surface finish of cylindrical workpieces. Unlike other grinding methods where the workpiece is held in a chuck or fixture, centerless grinding relies on the use of a regulating wheel and a grinding wheel working together to maintain consistent dimensional tolerances. This method allows for high-speed grinding of various materials, including metals, plastics, and composites.

The compact size of mini centerless grinders makes them ideal for smaller operations or specific applications where larger machines may be too cumbersome or too costly. These grinders typically weigh less, consume less floor space, and can be easily integrated into existing workflows.

Benefits of Discount Mini Centerless Grinders

1. Cost-Effective One of the primary benefits of discount mini centerless grinders is their affordability. They offer manufacturers the opportunity to invest in high-precision machinery without the hefty price tag associated with larger industrial equipment. Often, these grinders come equipped with varying wheel sizes and capabilities to cater to different applications, making them a savvy investment.

2. Space Saving For small workshops, space is often at a premium. The compact design of mini centerless grinders allows manufacturers to optimize their floor space. The smaller footprint enables them to incorporate additional machines or tools, enhancing overall productivity.

3. Ease of Use Mini centerless grinders are typically designed with user-friendliness in mind. Many models feature intuitive controls, making it easier for operators to learn how to use them quickly. This ease of operation can lead to reduced training time and faster onboarding for new employees.

4. Versatility Discount mini centerless grinders can handle a range of materials and product sizes. From small metal rods to larger cylindrical components, these grinders offer flexibility in production. Manufacturers can switch between tasks with minimal downtime, increasing throughput.

discount mini centerless grinder

5. Quality Output Just because a grinder is available at a discount does not mean that it compromises on quality. Many manufacturers produce discounted models without sacrificing the accuracy and consistency required in precision grinding. These machines are often capable of achieving tight tolerances essential in industries such as automotive, aerospace, and medical device manufacturing.

Choosing the Right Mini Centerless Grinder

When looking for a discount mini centerless grinder, several factors should be considered

- Specifications and Capabilities Assess the machine's specifications based on the materials you will be working with and the required tolerances. Not all grinders are suited for every application, so choose one that meets your needs.

- Brand Reputation Research various brands and read customer reviews to ensure you are purchasing from a reputable manufacturer.

- Customer Support and Warranty Opt for grinders that come with robust customer support and warranty options. This ensures that you are covered in case any issues arise post-purchase.

- Maintenance Requirements Look into how easy it is to maintain the machine. Regular maintenance is crucial for equipment longevity and performance.

Conclusion

In summary, discount mini centerless grinders represent a fantastic opportunity for businesses seeking to enhance their machining capabilities without breaking the bank. With their space-saving design, cost-effectiveness, and potential for high-quality output, they occupy a unique place in the manufacturing landscape. For companies looking to improve their grinding processes while managing budgets, these machines can offer the perfect solution. Whether you are a small shop owner or an industrial manufacturer, investing in a mini centerless grinder may just be the key to unlocking new levels of efficiency and precision in your operations.