Exploring Discounts on CNC Centerless Grinder Suppliers

The manufacturing industry has undergone a significant transformation in recent years, with many enterprises seeking advanced machinery to enhance productivity and efficiency. One such innovation is the CNC (Computer Numerical Control) centerless grinder, a crucial tool for precision grinding applications. With increasing demands for such equipment, suppliers have become vital partners for manufacturers. This article delves into the world of CNC centerless grinder suppliers and the importance of discounts in this competitive marketplace.

Understanding Centerless Grinding

Before we explore suppliers, it’s essential to understand what centerless grinding entails. Unlike traditional grinding methods where the workpiece is held between two centers, centerless grinding operates without these constraints. The workpiece is placed between a grinding wheel and a regulating wheel, allowing for continuous production without the need for precise alignment. This system not only increases throughput but also ensures high precision, making it suitable for manufacturing cylindrical components in various industries.

The Role of CNC in Centerless Grinding

CNC technology revolutionized the machining processes by integrating automation and computer control into manufacturing. CNC centerless grinders enhance the grinding process by providing consistent and repeatable results. They can be programmed for various grinding tasks, reducing the chances of human error and significantly improving production efficiency. As such, the demand for CNC centerless grinders has surged, leading to a competitive marketplace filled with numerous suppliers.

The Importance of Finding a Reliable Supplier

Selecting the right supplier is crucial for manufacturers looking to invest in CNC centerless grinders. A reliable supplier not only provides high-quality machines but also offers support in terms of maintenance, training, and after-sales service. Therefore, while searching for a supplier, businesses must consider several factors, including

1. Reputation Check reviews, testimonials, and case studies to gauge the supplier’s reliability and quality of service. 2. Experience Suppliers with extensive industry experience are often better equipped to meet your machining needs efficiently.

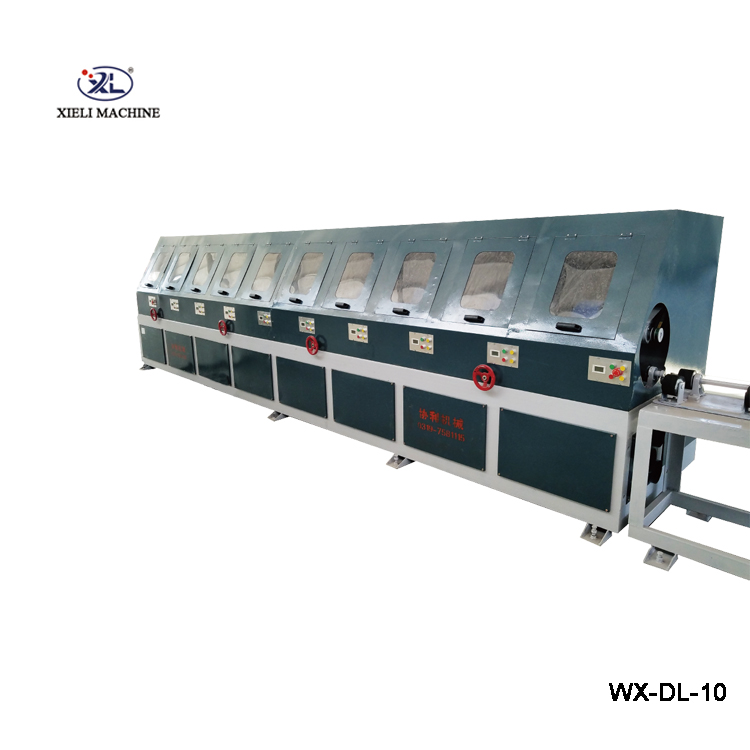

discount cnc centerless grinder suppliers

4. Product Range A wide range of products can be beneficial, allowing for future upgrades or replacements.

The Attraction of Discounts

Given the significant investment that CNC centerless grinders represent, discounts become particularly attractive. Many suppliers offer seasonal promotions, bulk purchase deals, or loyalty discounts, making it easier for manufacturers to invest in their operations.

1. Seasonal Promotions Certain times of the year, such as holidays or fiscal year-end, might see suppliers offering special discounts to boost sales. Companies can take advantage of these offers to secure better pricing.

2. Bulk Purchase Discounts For larger operations or businesses planning to overhaul their grinding capabilities, purchasing multiple units from a supplier can lead to substantial cost savings. Bulk discounts are often negotiated directly with the supplier.

3. Loyalty Programs Establishing a relationship with a supplier may also result in loyalty discounts. Suppliers often value long-term relationships and reward repeat customers with better pricing, enhanced support, or additional services.

Researching Suppliers Online

In today’s digital age, researching suppliers has never been easier. Online platforms can provide extensive information about various CNC centerless grinder suppliers. Comparative analysis of pricing, specifications, and customer reviews can facilitate informed decisions. Furthermore, many suppliers have started to use e-commerce platforms to display their discounts and promotions, making it convenient for manufacturers to find the best deals.

Conclusion

The CNC centerless grinder market is thriving, and the importance of finding trustworthy suppliers cannot be overstated. Manufacturers must remain vigilant in their search for reliable partners, weighing factors such as reputation, service, and product range while keeping an eye on attractive discounts. By doing so, they can maximize their investment, enhance productivity, and maintain a competitive edge in the ever-evolving manufacturing landscape. Whether through seasonal promotions, bulk purchase options, or loyalty agreements, manufacturers can leverage discounts to achieve their operational goals efficiently.