The Importance of Discount Centerless Grinder for Precision Grinding

In the realm of modern manufacturing, precision grinding plays a vital role in ensuring the high quality of machined components. Among the various grinding techniques, centerless grinding has gained immense popularity due to its ability to produce cylindrical parts with exceptional accuracy. A key player in this process is the centerless grinder, particularly those that are available at discounted prices, which can significantly benefit small businesses and large manufacturers alike.

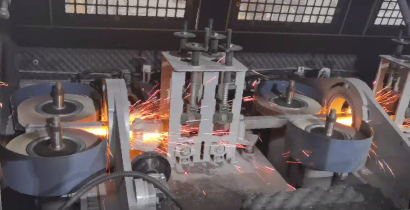

Centerless grinding is a method that allows the processing of workpieces without the need for a chuck or fixture. Instead, the part is supported by a blade and ground between two wheels, known as the regulating wheel and the grinding wheel. This unique setup not only increases efficiency but also reduces setup time, making it an attractive option for companies looking to optimize their production lines.

The availability of discount centerless grinders makes this advanced technology accessible to a wider range of businesses. Many manufacturers seek quality equipment without straining their budgets. Discounted centerless grinders can provide the same precision and reliability as premium models. These machines can handle various materials, including metals and plastics, making them versatile tools in the manufacturing process.

discount centerless grinder precision grinding

Investing in a discount centerless grinder presents several advantages. First, it allows businesses to increase their production rates while maintaining high standards of accuracy. This is particularly crucial in industries such as automotive, aerospace, and medical device manufacturing, where tight tolerances are essential for product performance and safety. Additionally, these grinders often come equipped with advanced features, such as programmable controls and automated loading systems, further enhancing productivity.

Furthermore, the adoption of centerless grinding technology improves operational sustainability. Centerless grinders typically produce minimal waste, as they optimize material usage and reduce the need for secondary operations. This aligns with the growing emphasis on environmentally friendly manufacturing practices.

In conclusion, discount centerless grinders are an invaluable asset for any manufacturing setup focused on precision grinding. By reducing costs while maintaining quality, these machines empower businesses to meet market demands and enhance their competitive edge. Embracing this technology is a significant step toward streamlining production processes and ensuring the delivery of high-quality components. As industries continue to evolve, the importance of cost-effective solutions like discount centerless grinders will undoubtedly remain at the forefront of modern manufacturing.