Discount Centerless Grinder Manufacturers A Guide to Affordable Precision Engineering

In the ever-evolving landscape of manufacturing, precision engineering plays a crucial role in ensuring that products meet stringent quality standards. Centerless grinding is a popular method utilized in various industries for its ability to produce high-precision parts with excellent surface finishes. For businesses looking to equip their facilities with centerless grinders, finding reliable manufacturers that offer competitive pricing is essential. This article explores the advantages of discount centerless grinder manufacturers and what to consider when sourcing these machines.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from a workpiece using a grinding wheel and a regulating wheel. Unlike traditional grinding, where the workpiece is held between two centers, centerless grinding allows for continuous feeding of the material without needing additional support. This efficiency translates into higher production rates, making centerless grinders an attractive option for manufacturers of all sizes.

Why Choose Discount Centerless Grinder Manufacturers?

1. Cost Savings The most apparent advantage of sourcing from discount manufacturers is the cost savings involved. These companies often provide competitively priced equipment without significantly compromising quality. This allows businesses, especially small and medium-sized enterprises, to access high-quality machinery that fits within their budget.

2. Variety and Options Discount centerless grinder manufacturers often offer a diverse range of models and specifications. This variety enables businesses to choose machines that align with their specific production needs, whether they require high-speed grinding, precision features, or specialized configurations.

3. Innovative Technologies Many discount manufacturers stay competitive in the market by incorporating the latest technology into their machines. These innovations often enhance productivity, improve accuracy, and reduce maintenance costs, allowing businesses to achieve more with less investment.

4. Support and Service Established discount manufacturers typically offer robust technical support and after-sales services. This includes installation assistance, operator training, and access to spare parts, ensuring that businesses can maintain their equipment efficiently and minimize downtime.

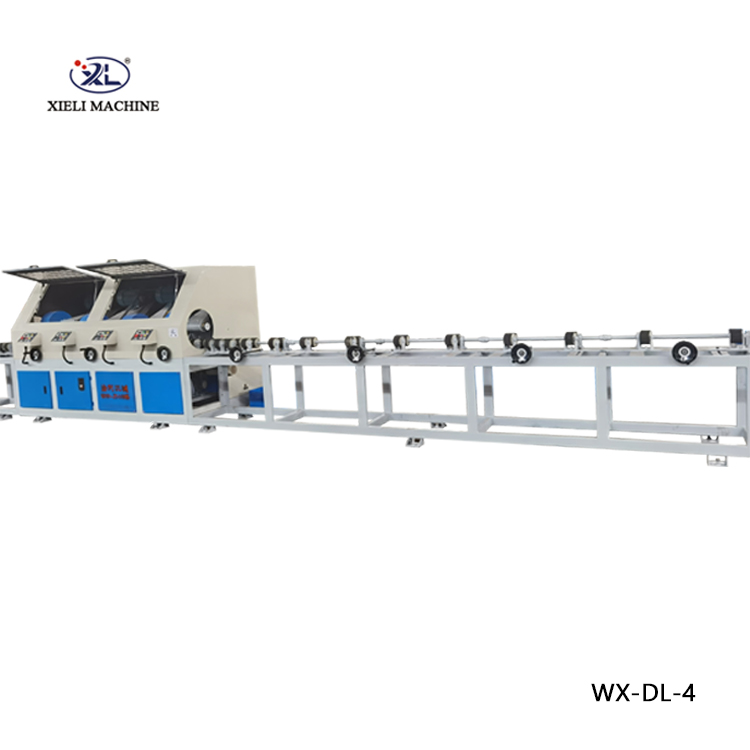

discount centerless grinder manufacturers

What to Consider When Sourcing Centerless Grinders

When selecting a discount centerless grinder manufacturer, several factors should influence your decision

1. Quality Assurance It's crucial to evaluate the manufacturer's commitment to quality. Look for companies that adhere to international manufacturing standards and have a reputation for producing reliable machinery. Customer reviews and testimonials can provide insight into the performance and durability of their products.

2. Customization Options Depending on your specific application, you may need customized features or configurations. Ensure that the manufacturer offers adaptable solutions that can be tailored to your unique requirements.

3. Warranty and Support A robust warranty can protect your investment. Be sure to inquire about the warranty period and what it covers. Additionally, assess the level of technical support available to assist you post-purchase.

4. Delivery and Installation Timely delivery of equipment is critical to maintaining production schedules. Choose a manufacturer that offers efficient shipping options and has a clear installation process to facilitate a smooth setup.

Conclusion

In conclusion, discount centerless grinder manufacturers present an excellent opportunity for businesses seeking affordable yet high-quality machining solutions. By considering the factors mentioned above and conducting thorough research, manufacturers can find the right equipment that meets their production needs without breaking the bank. With the right centerless grinder in place, companies can enhance their manufacturing processes, improve product quality, and ultimately achieve greater competitiveness in the market. Whether you are an established firm or a startup, investing in a centerless grinder from a discount manufacturer could be a wise strategic move for your business success.