Understanding the Discount Centerless Cylindrical Grinding Machine A Game Changer for Precision Manufacturing

In the realm of precision manufacturing, the centerless cylindrical grinding machine plays a pivotal role. This machine is designed to grind cylindrical parts without the need for a supporting structure, resulting in superior dimensional accuracy and surface finish. Recently, the availability of discount centerless cylindrical grinding machines has become a game changer for businesses seeking to enhance their production capabilities while maintaining a budget.

The centerless grinding process is uniquely suited for high-volume production runs, making it an essential tool for industries such as automotive, aerospace, and manufacturing. The machine operates by holding the workpiece between a grinding wheel and a regulating wheel, allowing for continuous operation without the need for manual intervention. This design not only optimizes throughput but also minimizes the risks of part distortion, which is crucial when dealing with tightly toleranced components.

One of the primary benefits of investing in a discount centerless cylindrical grinding machine is cost savings. These machines provide an affordable entry point for smaller manufacturers or startups that may have previously struggled to afford such advanced equipment. With advancements in technology, many manufacturers now offer high-quality, yet cost-effective, machines capable of delivering the same performance standards as their more expensive counterparts. This democratization of technology allows more companies to compete in the market while maintaining high production values.

discount centerless cylindrical grinding machine

Moreover, the durability and reliability of modern centerless cylindrical grinding machines are significant. Despite their lower price points, these machines are engineered with robust components designed to withstand the rigors of continuous operation. Users can expect longevity and consistent performance, minimizing downtime and maintenance costs. These factors contribute to a lower total cost of ownership, making them appealing for businesses focused on efficiency and productivity.

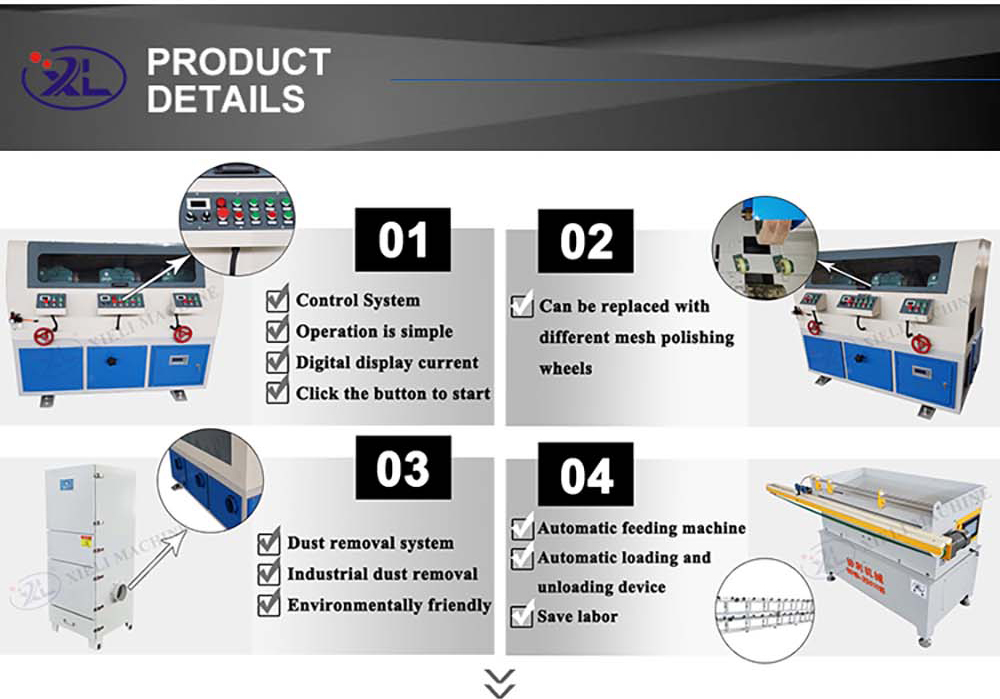

In addition to being cost-effective, discount centerless cylindrical grinding machines also come equipped with advanced features that enhance operational efficiency. Innovations such as CNC controls, automation capabilities, and real-time monitoring systems provide manufacturers with greater flexibility and control over their grinding processes. These features not only improve accuracy but also enable operators to adjust settings on-the-fly, reducing the risk of errors and rework.

Furthermore, the market for these machines is expanding, with more suppliers offering a variety of models to suit different production needs. Whether you're processing small, intricate parts or larger components, there is likely a discount centerless cylindrical grinding machine tailored to your specific requirements.

In conclusion, the rise of discount centerless cylindrical grinding machines heralds a new era for precision manufacturing. Offering an unbeatable combination of cost savings, efficiency, and technological advancement, these machines are essential tools for businesses aiming to thrive in an increasingly competitive market. By embracing this technology, manufacturers can achieve remarkable levels of precision and quality in their production processes, positioning themselves for success in the future.