Understanding Discount Centerless Cylindrical Grinding Machines

Centerless cylindrical grinding machines are crucial in various manufacturing processes, allowing for the precise shaping and smoothing of cylindrical parts. These machines operate on the principle that workpieces are held between two rotating wheels, with the grinding wheel providing the grinding action while the regulating wheel controls the speed and movement of the part. The efficiency and precision of centerless grinding make it a preferred choice for numerous industries, including automotive, aerospace, and medical.

One of the significant advantages of centerless grinding is its ability to deliver high production rates while maintaining tight tolerances. This process eliminates the need for aligning the workpiece, as it can be fed continuously into the grinding area. As a result, manufacturers can produce large volumes of parts with consistent quality, reducing production times and increasing overall efficiency.

In today’s competitive market, cost control is essential. This is where discount centerless cylindrical grinding machines come into play. These machines offer a cost-effective solution for businesses looking to enhance their production capabilities without breaking the bank. Discount options may refer to either pre-owned machinery that has been refurbished and meets quality standards or models from manufacturers that provide budget-friendly pricing without compromising on technology and performance.

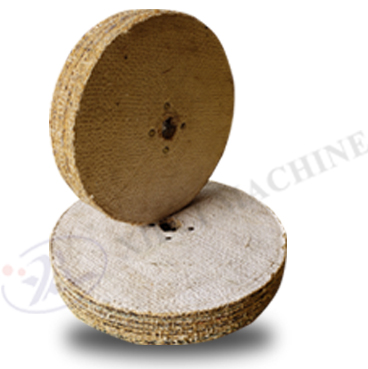

discount centerless cylindrical grinding machine

When considering purchasing a discount centerless cylindrical grinding machine, it is vital to assess the machine's specifications thoroughly. Key aspects to consider include the size of the machine, the type of grinding wheel it uses, the maximum diameter and length of parts it can accommodate, and the level of automation available. Additionally, support and service agreements are paramount to ensure that any maintenance needs can be addressed promptly, keeping downtime to a minimum.

Investing in a discount centerless cylindrical grinding machine should align with long-term operational goals. Companies should focus on the return on investment by evaluating the initial cost against the potential savings in production efficiency and reduced waste. Furthermore, exploring financing options or leasing arrangements can also make acquiring such machinery more accessible for small to medium-sized enterprises.

In conclusion, discount centerless cylindrical grinding machines represent a valuable resource for businesses aiming to optimize their manufacturing processes. By balancing cost and performance, manufacturers can achieve remarkable efficiency and precision, keeping them competitive in an ever-evolving industrial landscape.