Understanding Discount Centerless Grinder Tooling

In the world of precision machining, the importance of centerless grinding cannot be overstated. This method allows for the efficient processing of parts by eliminating the need for supporting fixtures as the workpiece is held in place by the grinding wheel and a regulating wheel. This dynamic setup not only increases production efficiency but also ensures consistent dimensional accuracy. However, to achieve optimal results, the right tooling is essential—a factor often overlooked in discussions about centerless grinding.

Discount centerless grinder tooling offers a cost-effective solution for businesses looking to maintain high-quality output while managing their budgets. These tooling options can encompass a range of components, including grinding wheels, diamond wheels, regulating wheels, and even the necessary accessories such as dressers and arbors. By sourcing these tools at discounted rates, manufacturers can significantly lower their operational costs without compromising on quality.

One of the primary advantages of utilizing discount tooling is the accessibility it provides to smaller manufacturers and shops. High-quality centerless grinding is often associated with high costs, which can make it prohibitive for smaller entities to invest in state-of-the-art equipment. However, with affordable tooling options, these businesses are empowered to compete in markets where precision and reliability are paramount.

When selecting discount centerless grinder tooling, it is important to consider several key factors. First and foremost is the material used in the tooling. High-quality materials contribute to the longevity and performance of the tools, reducing the frequency of replacements and maintenance. Synthetic bond wheels or ceramic wheels, for instance, may provide better performance than lower-quality options and can ultimately save costs in the long run.

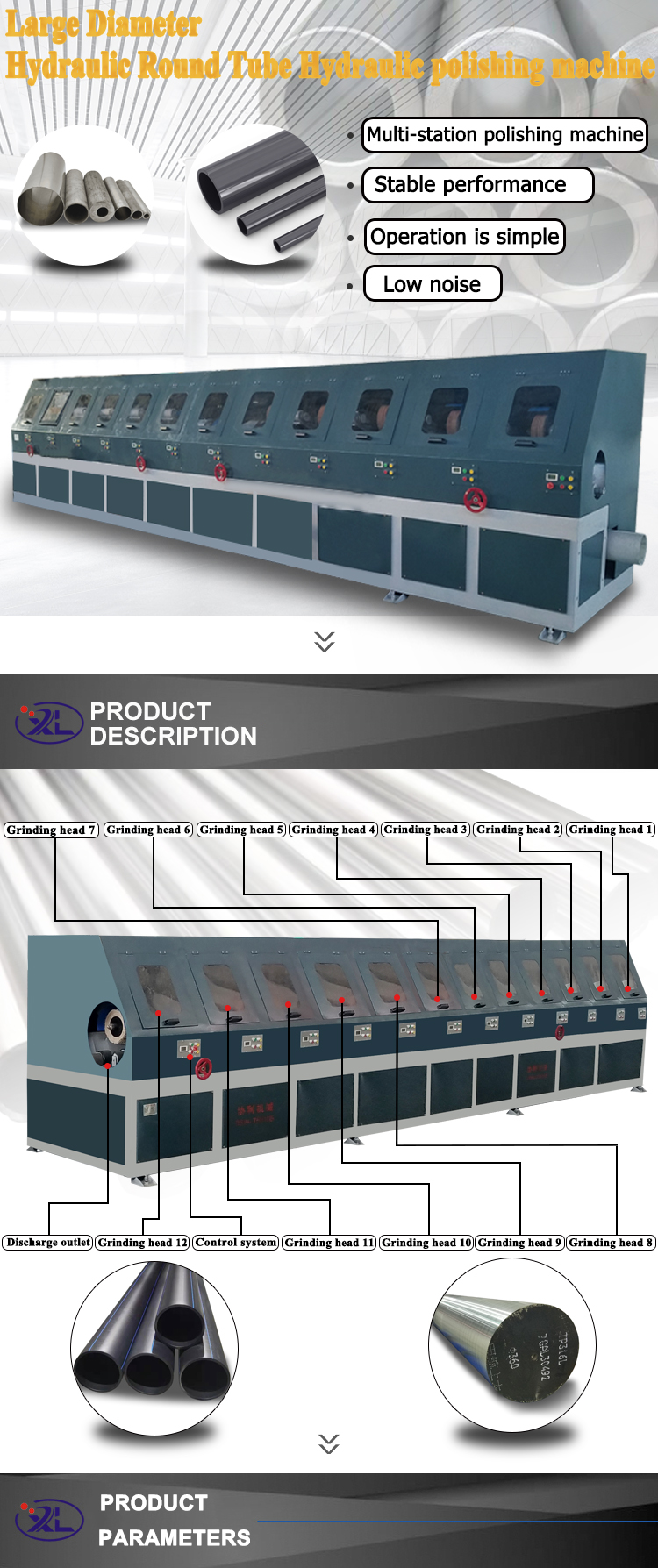

discount centerless grinder tooling

Additionally, it’s essential to choose the right specifications for the grinding wheels. The size, grit type, and bond type can affect the outcomes of the grinding process, including surface finish and metal removal rate. For many businesses, the ability to customize tooling to match specific job requirements can lead to greater efficiency and productivity.

Another aspect to consider is sourcing from reputable suppliers who specialize in discount centerless grinder tooling. The market is rife with options, but not all suppliers maintain high standards of quality. Researching suppliers and seeking reviews or testimonials can help ensure that the tooling purchased meets industry standards. Investments in quality tooling improve the overall performance of the grinding process, leading to superior part quality and repeatability.

Moreover, while discount centerless grinder tooling may offer reduced prices, it does not mean that the tools lack innovation. Many suppliers provide advanced tooling technologies at competitive prices. These may include features designed to enhance precision, reduce wear, or improve cooling during the grinding process. Some companies also offer tooling that incorporates advanced materials, promising higher grinding efficiency and longer tool life.

In conclusion, discount centerless grinder tooling presents a viable option for manufacturers who aim to balance quality with cost-effectiveness. By making informed choices, businesses can harness the full potential of centerless grinding techniques, enhancing their productivity and ensuring the precision of their products. As the industry continues to evolve, the right tooling remains central to achieving operational success and maintaining a competitive edge in the machining sector.