Understanding Discount Centerless Grinder Tooling

In the world of manufacturing and metalworking, precision is paramount. Centerless grinding has emerged as a highly efficient method for achieving this precision, especially when it comes to the production of cylindrical parts. The tooling used in centerless grinding plays a critical role in the quality of the final product, making it essential for businesses to invest wisely.

Centerless grinding machines excel in creating round parts without the need for support between the grinding wheels. This process is particularly beneficial for high-volume production, where speed and efficiency are key. However, to maintain optimal performance, appropriate tooling must be employed. That’s where discount centerless grinder tooling comes into the conversation.

What is Centerless Grinder Tooling?

Centerless grinder tooling typically includes components like grinding wheels, regulating wheels, and support fixtures. The grinding wheel does the actual grinding, while the regulating wheel controls the part's feed rate and rotation. The correct selection and maintenance of these tools are vital for achieving the desired surface finish and dimensional accuracy.

The Importance of Quality Tooling

Choosing high-quality tooling for centerless grinders can impact not only the costs associated with producing parts but also the overall productivity of the operation. Discount tooling options may be appealing due to lower prices, but it’s crucial to ensure that these products do not compromise quality. High-quality tooling can enhance productivity, reduce downtime, and improve the lifespan of the equipment, ultimately providing a better return on investment.

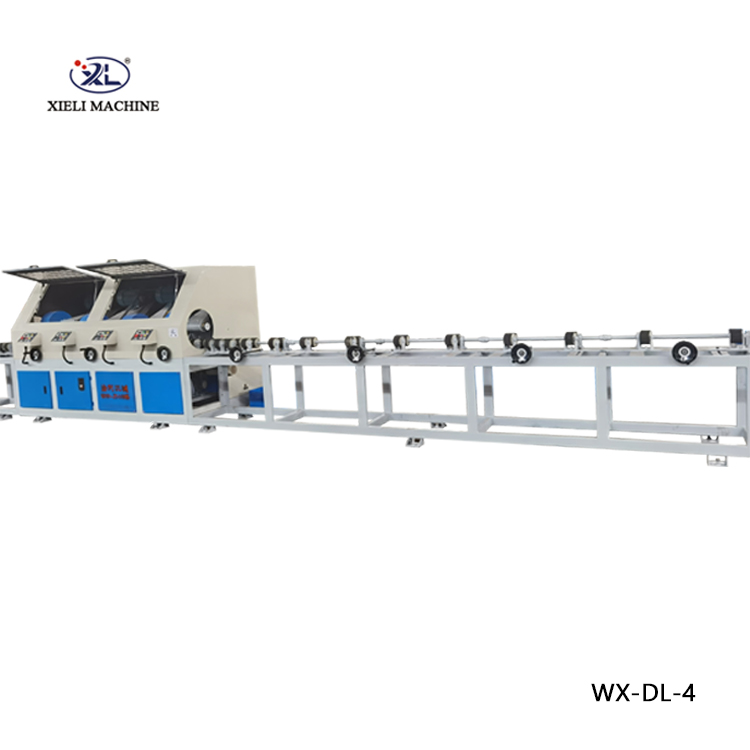

discount centerless grinder tooling

Benefits of Discount Tooling

Discount centerless grinder tooling can provide significant financial benefits, especially for small to medium-sized enterprises. These tools can offer the same essential features and capabilities as their premium counterparts but at a fraction of the cost. Budget-conscious manufacturers can thus optimize their operations without overshooting their financial limits.

Moreover, with the rise of e-commerce and specialized suppliers, finding discount tools that do not sacrifice quality has become more accessible. Many suppliers offer warranties and satisfaction guarantees with their products, which can further mitigate risks associated with purchasing lower-cost options.

Final Thoughts

When considering discount centerless grinder tooling, manufacturers should weigh the long-term benefits against initial costs carefully. While price is an important factor, the tooling’s quality will ultimately determine the operational efficiency and output quality of the machining process.

Investing in reliable discount tooling can provide competitive advantages, allowing manufacturers to enhance their productivity while minimizing operational costs. Always remember to conduct thorough research and check customer reviews to ensure that discount options align with the high standards expected in modern manufacturing.

In conclusion, the right centerless grinder tooling is paramount to ensuring precision, efficiency, and profitability in machining operations. By navigating the market thoughtfully, businesses can secure the best tools for their needs without breaking the bank.