The Benefits of Discount Centerless Finish Grinders

In the realm of precision manufacturing, centerless grinding has emerged as a vital process for producing high-quality finishes on various components. Among the options available, discount centerless finish grinders offer significant advantages for businesses seeking efficiency without compromising quality.

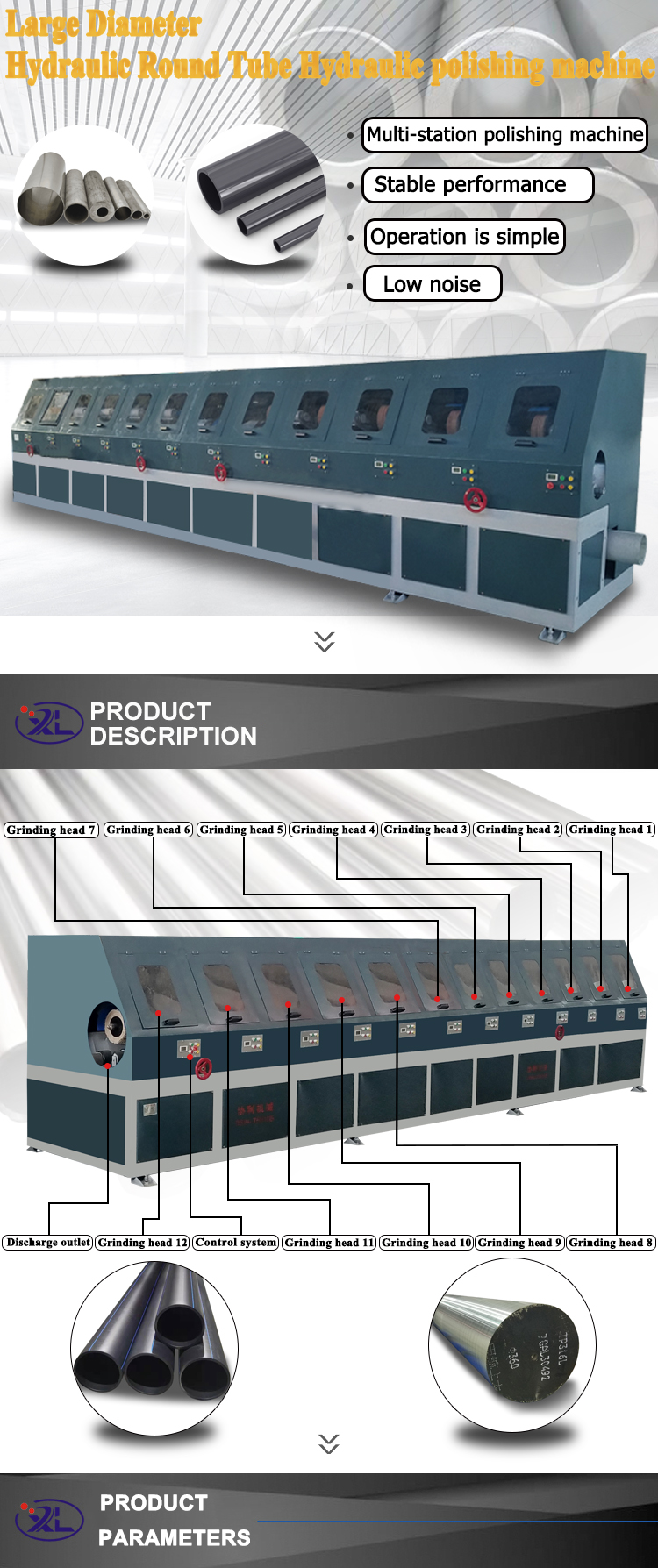

Centerless grinding is a technique utilized to shape the outer surfaces of cylindrical workpieces. Unlike traditional grinding methods, centerless grinders do not require the workpiece to be mounted between centers. Instead, it is held in place by a combination of a grinding wheel, a regulating wheel, and a conveyor system. This offers several key benefits, particularly when using discount models that still maintain reliable performance.

One of the most prominent advantages of purchasing discount centerless finish grinders is cost savings. These machines can significantly reduce upfront expenses, making high-precision manufacturing accessible to smaller businesses or startups looking to optimize their production capabilities. Despite the lower price point, many discount models still deliver impressive accuracy and finish quality, enabling companies to maintain competitive standards.

discount centerless finish grinder

Moreover, discount centerless finish grinders often incorporate advanced features that enhance productivity and efficiency. Many of these machines are designed for ease of use, allowing operators to change setups quickly and minimize downtime. Enhanced automation features, such as programmable controls and in-process measurement systems, can further streamline operations, leading to reduced labor costs and increased throughput.

Another noteworthy benefit of discount centerless finish grinders is their versatility. These machines can handle a wide range of materials and component sizes, making them suitable for various industries, including automotive, aerospace, and medical device manufacturing. This adaptability allows businesses to be more agile in responding to changing market demands and customer requirements.

Furthermore, investing in discount centerless finish grinders supports a sustainable approach to manufacturing. By optimizing the grinding process, these machines not only reduce material waste but also enhance energy efficiency. Employing energy-efficient machinery aligns with modern environmental standards and corporate sustainability goals, appealing to both consumers and regulatory bodies.

In conclusion, discount centerless finish grinders present an excellent opportunity for companies to enhance their manufacturing processes while remaining cost-effective. By combining affordability with advanced features, these machines allow businesses to maintain high-quality standards and improve their operational efficiency. As the industry continues to evolve, embracing technological advancements through cost-effective solutions will be essential for maintaining a competitive edge in the market.