Understanding the Pricing of Cylindrical Polishing Machines

Cylindrical polishing machines are an essential tool in various industries, including manufacturing, automotive, aerospace, and metalworking. As these machines play a crucial role in enhancing the surface finishes of cylindrical workpieces, it is vital for businesses to comprehend the pricing structures, features, and market trends associated with these machines. This article will delve deeper into understanding the factors influencing the pricing of cylindrical polishing machines and provide a general overview of what to expect in the market.

Factors Influencing Pricing

1. Machine Specifications The price of cylindrical polishing machines can significantly vary depending on their specifications. These specifications include motor power, polishing speed, size of the workpiece it can handle, and the type of polishing mechanisms used. Machines with higher power and advanced features tend to be priced higher due to their enhanced capabilities and efficiency.

2. Quality of Build and Components The materials used in constructing the machine can affect its price. For example, machines made from high-grade steel or featuring advanced engineering designs may incur higher costs. Durable components will not only improve the performance but also prolong the lifespan of the machine, making them a worthwhile investment.

3. Brand Reputation Just like in any other market, brand reputation plays a crucial role in the pricing of cylindrical polishing machines. Established manufacturers with a proven track record are likely to command higher prices due to their reliability and customer support. On the other hand, lesser-known brands may offer more competitive pricing to attract customers but may not provide the same level of assurance regarding product longevity and service.

4. Technology and Automation The advent of technology in manufacturing has led to the development of semi-automated and fully automated cylindrical polishing machines. These machines often come with advanced features such as programmable controls, real-time monitoring, and integrated polishing techniques that greatly enhance productivity. The incorporation of these technologies typically leads to higher prices, but the increase in efficiency can justify the investment.

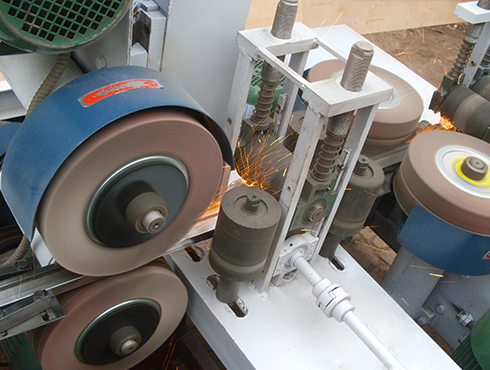

cylindrical polishing machine pricelist

5. Custom Features Some businesses require bespoke solutions tailored to their specific needs. Custom-built cylindrical polishing machines that cater to unique production requirements can significantly affect pricing. While these machines may have a higher upfront cost, they can provide significant long-term benefits by streamlining operations and improving product quality.

Market Trends

The market for cylindrical polishing machines is currently experiencing notable trends that impact pricing. With the increasing demand for high-precision finishing in various industries, manufacturers are responding by investing in the development of more sophisticated machines. Consequently, this has led to a broader range of options available in the market, catering to different price points.

Moreover, the rising emphasis on eco-friendly manufacturing processes is prompting manufacturers to adopt sustainable practices in producing polishing machines. More efficient machines that use less energy or have built-in waste recycling features are emerging, which can affect their pricing. While the initial investment may be higher, the long-term savings on energy costs and environmental impact can be advantageous.

Conclusion

In summary, the pricing of cylindrical polishing machines varies greatly based on several factors, including machine specifications, build quality, brand reputation, technology, and custom features. Additionally, market trends such as the demand for high-precision finishes and eco-friendly solutions are reshaping the landscape of cylindrical polishing machines. For businesses looking to invest in these machines, it is essential to evaluate their specific needs and compare different options available in the market thoroughly.

Whether you are a small workshop looking for a basic model or a large manufacturer in need of advanced automated systems, understanding these pricing dynamics will help you make a more informed decision. Ultimately, a well-chosen cylindrical polishing machine can lead to enhanced productivity, superior surface finishes, and improved overall operational efficiency, making it a valuable asset in any industrial setting.