The Rise of Cylindrical Polishing Machine Manufacturers

In an era of rapid technological advancement, the demand for high-precision manufacturing processes has surged. Among the many innovations, cylindrical polishing machines have gained prominence. These machines are crucial for achieving smooth surfaces on cylindrical parts, which is essential for various industries, including automotive, aerospace, and manufacturing. As a result, the market for cylindrical polishing machine manufacturers is thriving, attracting numerous players eager to meet industry demands.

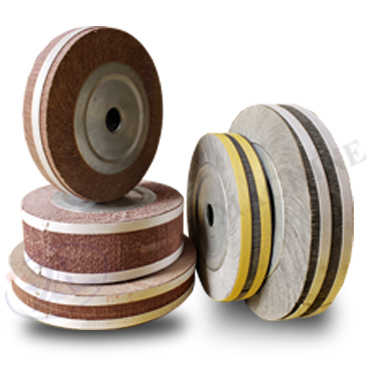

Cylindrical polishing machines are designed to refine the surface finish of cylindrical components by removing imperfections and enhancing their aesthetic appeal. The process increases the corrosion resistance of parts, ensuring longevity and optimal performance in their respective applications. Given the increasing complexity of modern engineering requirements, manufacturers are continuously developing more efficient machines that not only improve polishing speed but also enhance the quality of the finish.

The growth of the cylindrical polishing machine market can be attributed to several factors. First, the rising standards in manufacturing quality have pushed companies to invest in advanced polishing machines to remain competitive. Second, industries such as aerospace and automotive require high-performance components with flawless finishes, thus increasing the demand for specialized polishing solutions. Furthermore, the trend toward automation has led manufacturers to incorporate robotics and smart technologies, resulting in more precise and efficient polishing processes.

cylindrical polishing machine manufacturers

In response to this burgeoning demand, numerous cylindrical polishing machine manufacturers have emerged worldwide, each vying to carve out a niche in the market. Established companies are continuously innovating their product lines, offering machines that are adaptable to various materials, including metals, plastics, and composites. Additionally, many manufacturers provide customized solutions tailored to specific industry requirements, enhancing their appeal to a broader client base.

Sustainability is another key trend influencing the cylindrical polishing machine sector. Many manufacturers are focusing on developing eco-friendly polishing solutions that minimize waste and energy consumption. This shift not only addresses environmental concerns but also promotes cost efficiency for companies that prioritize sustainable practices.

As the landscape of manufacturing continues to evolve, cylindrical polishing machine manufacturers are expected to play a pivotal role in shaping the future of production. By embracing innovation, quality, and sustainability, these manufacturers are set to not only meet the current needs but also anticipate the future demands of diverse industries, ensuring they remain at the forefront of technological advancement. The cylindrical polishing machine market is indeed a dynamic field that reflects the broader trends impacting the manufacturing sector globally.