The Rise of Cylindrical Polishing Machine Exporters

In the global manufacturing landscape, cylindrical polishing machines have carved out an essential niche. These machines are pivotal in various sectors, including automotive, aerospace, and metal fabrication, owing to their ability to enhance the surface finish of cylindrical parts. As industries continually strive for quality and precision, the demand for efficient and high-quality cylindrical polishing machines has surged, consequently giving rise to a vibrant market for exporters.

Understanding Cylindrical Polishing Machines

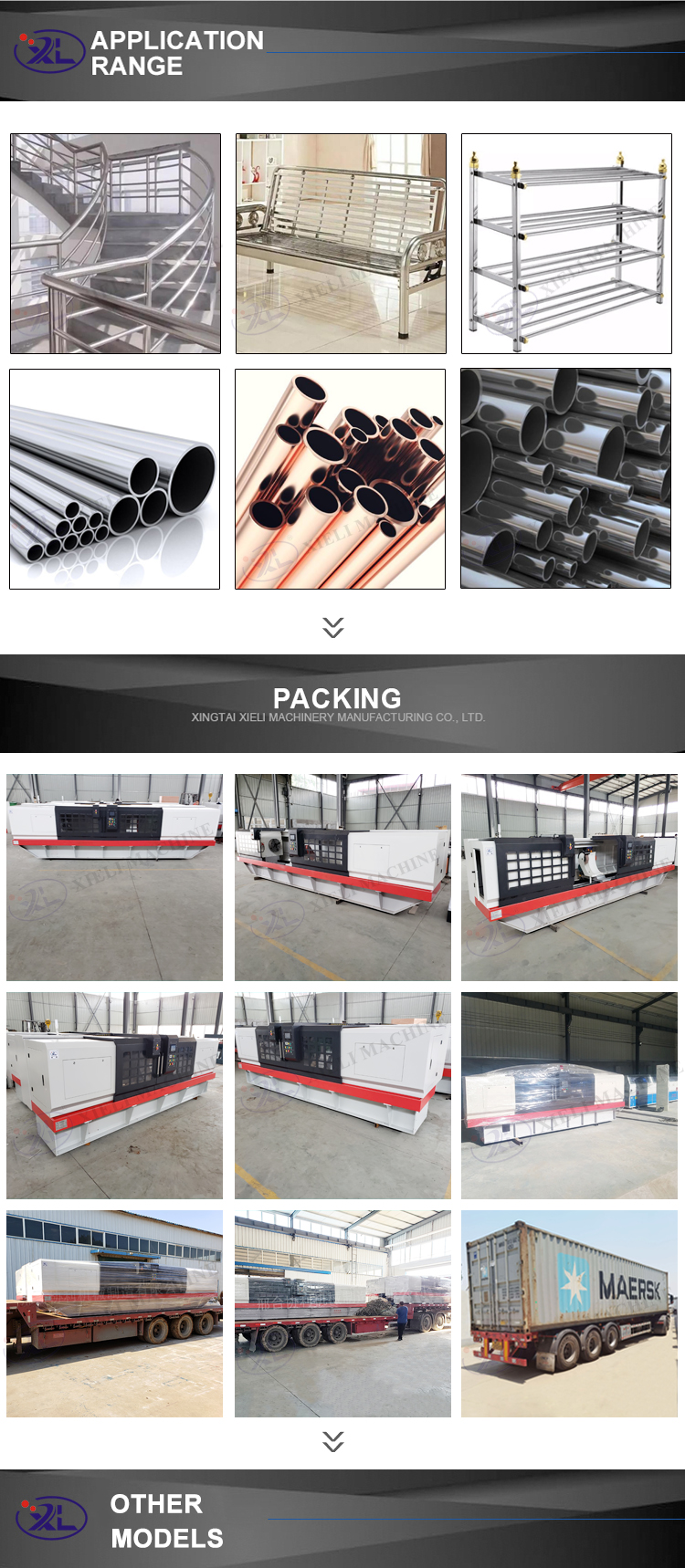

Cylindrical polishing machines are designed to refine the surface of cylindrical workpieces, ensuring they meet the stringent quality standards required in many applications. The polishing process involves the use of abrasives to remove imperfections, resulting in a smooth, shiny finish that can improve both functionality and aesthetics. The machines come in various types, including manual, semi-automatic, and fully automatic variants, each catering to different production scales and requirements.

The Export Market Dynamics

The export market for cylindrical polishing machines is influenced by several factors. First and foremost, the rapid industrialization in emerging economies has spurred demand for high-quality polishing machines. Countries such as China, India, and Brazil have seen a boom in manufacturing capabilities, leading to an increase in the need for advanced machinery.

Additionally, developed countries are upgrading their manufacturing facilities to enhance productivity and maintain competitiveness in a global market where precision is paramount. This trend has led to a consistent demand for sophisticated cylindrical polishing machines equipped with advanced technology.

Leading Exporters in the Industry

Several countries stand out as leaders in the export of cylindrical polishing machines. Germany, known for its engineering prowess, has been a dominant player, exporting high-quality machines that are renowned for their durability and efficiency. Similarly, Italy and Japan are also significant contributors to the export market, offering machines that blend cutting-edge technology with user-friendly designs.

cylindrical polishing machine exporters

Innovative exporters are focusing on research and development to enhance the effectiveness of their polishing machines. Integrating automation, smart technology, and ergonomics has become a priority, enabling manufacturers to maximize output while minimizing downtime.

Challenges Faced by Exporters

Despite the promising landscape for cylindrical polishing machine exporters, there are challenges that significantly impact the industry. One of the primary issues is the fluctuating cost of raw materials, which can affect production costs and pricing strategies. Furthermore, stricter regulations regarding safety and environmental standards are necessitating continual adjustments in machine design and production processes.

Additionally, competition among exporters is intensifying. With numerous players in the market, standing out requires not only innovation but also establishing strong relationships with customers. Effective marketing strategies and after-sales support have become crucial differentiators in retaining and attracting clients.

The Future of the Industry

Looking ahead, the future of cylindrical polishing machine exporters appears promising. The ongoing evolution of manufacturing technologies, including the adoption of Industry 4.0 principles, is set to revolutionize the polishing process. As companies look to enhance productivity and customization, there will be a growing need for versatile machines capable of adapting to diverse applications.

Moreover, trends such as sustainability and energy efficiency will shape the design and functionality of new models. Exporters who can innovate while adhering to these principles are likely to thrive in the competitive landscape.

In conclusion, cylindrical polishing machine exporters play a crucial role in supporting the manufacturing sector's pursuit of quality and efficiency. By overcoming challenges and leveraging technological advancements, they are set to make significant contributions to the global market. As industries continue to evolve, the demand for advanced cylindrical polishing solutions will only increase, establishing a pathway for further growth and innovation within the export sector.