Exploring the Cylindrical Polishing Machine Factory Innovations and Applications

In the manufacturing industry, the demand for precision and high-quality finishing processes is paramount. One of the key players in achieving such standards is the cylindrical polishing machine. As industries ranging from automotive to aerospace seek to enhance the aesthetics and functionality of their products, the role of cylindrical polishing machines becomes increasingly significant. This article delves into the workings of a cylindrical polishing machine factory, exploring its innovations, processes, and the impact it has on various sectors.

Understanding Cylindrical Polishing

Cylindrical polishing is a process used to achieve a smooth and shiny finish on cylindrical surfaces. This type of polishing is crucial in applications where friction between cylindrical components can lead to wear over time. Components such as shafts, rods, and tubes often require a polished finish to improve their performance and durability. The cylindrical polishing machine achieves this by using abrasive materials that are rotated around the workpiece, effectively removing surface imperfections and enhancing the overall surface quality.

The Factory Environment

A cylindrical polishing machine factory is a hub of innovation, incorporating advanced technologies to streamline production. The factory is typically organized into several sections raw material procurement, machine assembly, quality control, and finishing. Each section plays a pivotal role in ensuring that the end product meets the required specifications.

1. Raw Material Procurement The factory begins its journey by sourcing high-quality raw materials. Stainless steel, aluminum, and other metals are selected for their durability and resistance to corrosion. The quality of raw materials directly affects the performance of the polishing machines.

2. Machine Assembly The heart of the factory lies in the assembly of cylindrical polishing machines. Skilled engineers and technicians work meticulously to integrate advanced technologies such as CNC (Computer Numerical Control) systems, robotic arms, and precision grinding tools. These innovations not only improve the efficiency of the polishing process but also ensure consistency and accuracy in the final product.

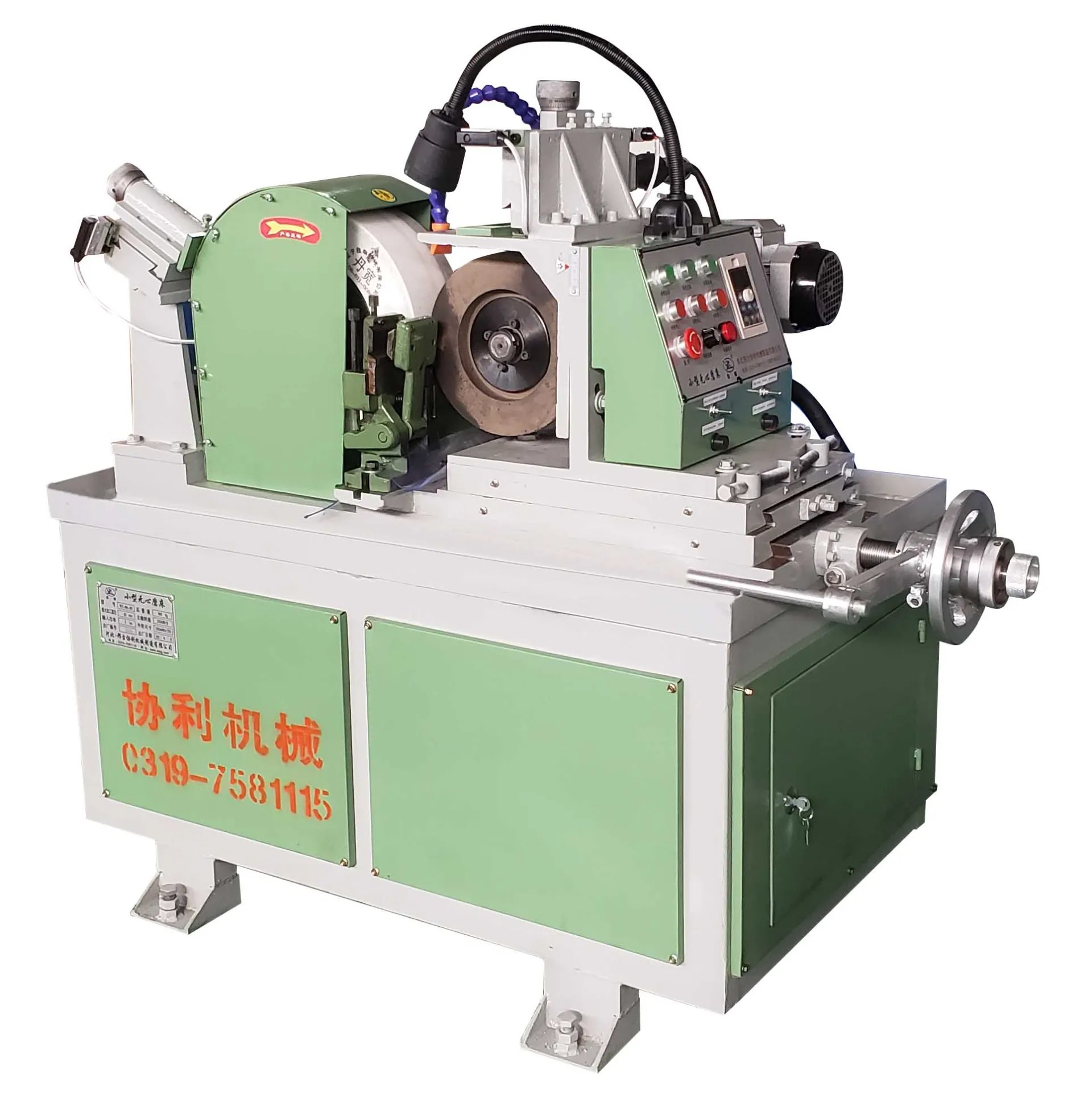

cylindrical polishing machine factory

3. Quality Control After assembly, each machine undergoes rigorous testing and quality control. Various parameters such as polishing speed, surface finish quality, and durability are assessed to ensure that the machines can meet the diverse needs of their clients. This stage is crucial, as any discrepancy can lead to significant losses for manufacturers.

4. Finishing and Packaging Once the machines pass quality control, they are subjected to a finishing process where they are painted or coated to prevent corrosion. Afterward, the machines are carefully packaged, designed to withstand transportation while ensuring that they arrive at their destination in pristine condition.

Innovations in Cylindrical Polishing

The cylindrical polishing machine factory is continually evolving, embracing new technologies to stay competitive. Innovations such as automated systems and AI-driven controls are transforming the polishing landscape. These advancements not only enhance production efficiency but also allow for greater customization options, catering to specific client demands.

Furthermore, eco-friendly materials and processes are being incorporated to minimize the environmental impact of manufacturing. Sustainable practices such as waste recycling and the use of biodegradable polishing compounds are becoming standard in modern factories.

Conclusion

As industries continue to demand precision and high-quality finishes, the cylindrical polishing machine factory stands at the forefront of innovation. By combining advanced technology with skilled craftsmanship, these factories produce machines that play a critical role in various sectors. The ongoing advancements in cylindrical polishing machinery promise to enhance product quality further, making these factories essential to modern manufacturing. As the world moves towards greater technological integration and sustainability, the cylindrical polishing machine factory will undoubtedly continue to thrive, leading the way in producing superior finished products.