The Importance of Cylinder Polishing Machines in Modern Manufacturing

In the fast-paced world of manufacturing, precision and quality are paramount. One of the critical processes that ensures a high standard of production is polishing. Especially in industries that involve the use of cylinders, such as automotive, aerospace, and manufacturing equipment, cylinder polishing machines play a vital role. This article delves into the significance of these machines, their working principles, and their advantages in manufacturing processes.

What are Cylinder Polishing Machines?

Cylinder polishing machines are specialized equipment designed to enhance the surface finish of cylindrical components. These machines use various methods and tools to remove imperfections, burrs, and oxidation from the surface of metal cylinders. Typically, these machines can be found in workshops that focus on producing high-quality components for engines, hydraulic systems, and other intricate machinery.

Working Principles

The operation of a cylinder polishing machine typically involves rotating the cylinder against a polishing medium, which can include abrasive pads, brushes, or compounds. The process can be automated or performed manually, depending on the complexity and size of the components involved.

1. Preparation Before polishing, the cylinder is often cleaned to remove any dirt, oil, or debris. This step is crucial as contaminants can impede the polishing process and lead to undesirable surface finishes.

2. Polishing The polishing machine operates by applying a combination of rotational motion and the polishing medium against the cylinder's surface. For automated machines, programmable settings dictate the speed, pressure, and duration of polishing, ensuring consistent results.

3. Finishing Touches After the initial polishing, a secondary process may occur to achieve a finer finish. This could involve using lighter abrasives or finer polishing compounds, which elevate the surface quality to meet specific industry standards.

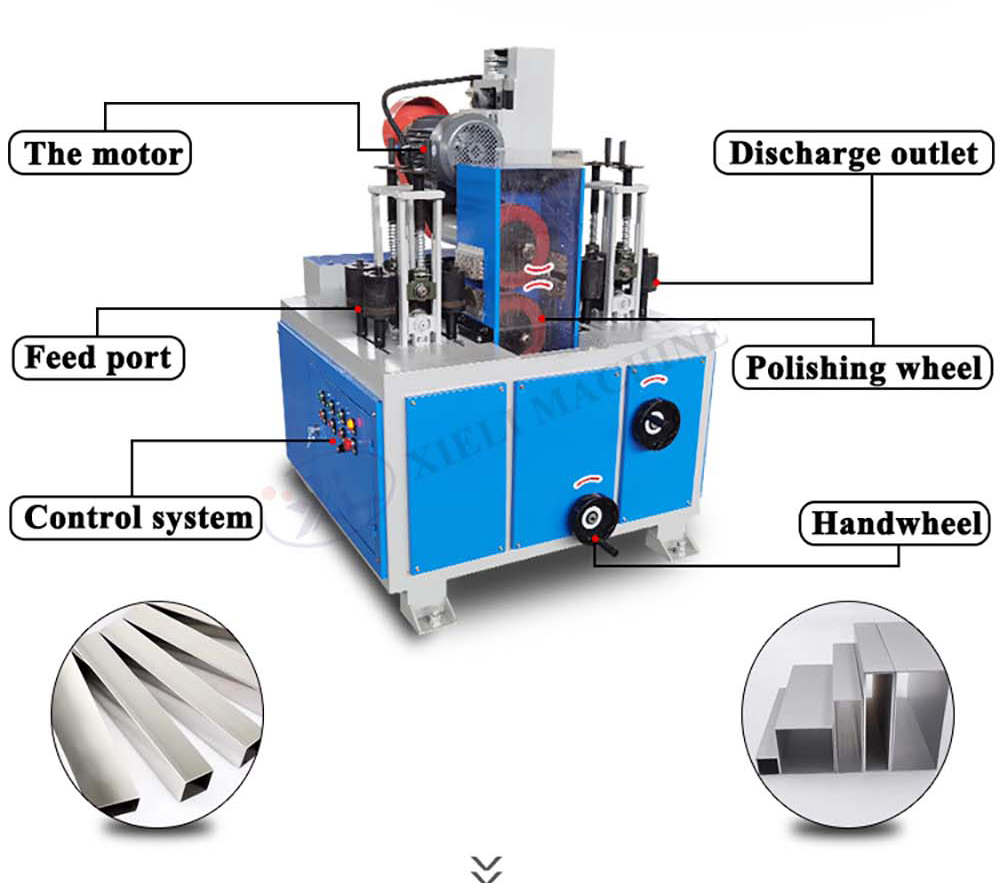

cylinder polishing machine

Advantages of Cylinder Polishing Machines

1. Enhanced Surface Quality The primary benefit of using a cylinder polishing machine is the improved surface finish. Polished cylinders exhibit reduced friction, which is essential in applications where smooth operation is critical, such as in engines or hydraulic systems.

2. Increased Durability A polished surface can enhance resistance to wear and corrosion, extending the lifespan of the components. This durability is vital in environments where cylinders are exposed to harsh conditions.

3. Precision Manufacturing Cylinder polishing machines offer consistent results, ensuring that each component meets stringent quality standards. This precision is critical in high-tolerance applications, where even minor inconsistencies can lead to significant operational issues.

4. Time Efficiency Automation in polishing processes significantly reduces production time. Machines can operate continuously and manage multiple components, increasing overall productivity in manufacturing setups.

5. Cost-Effective Solutions Though the initial investment in cylinder polishing machines can be substantial, the long-term savings due to reduced scrap rates, improved productivity, and enhanced product quality can offset these costs.

Applications in Industry

Cylinder polishing machines are utilized across various industries, including automotive, aerospace, and manufacturing equipment sectors. In automotive manufacturing, for instance, polished components such as pistons, cylinders, and shafts ensure optimal performance and efficiency. The aerospace industry also relies heavily on polished parts to meet safety and reliability standards, where even the slightest imperfections can compromise aircraft performance.

In conclusion, cylinder polishing machines are indispensable tools in modern manufacturing, providing enhanced surface finishes, increased durability, and economic efficiency. As industries continue to evolve towards automation and precision, the demand for advanced cylinder polishing techniques will only grow. Manufacturers must invest in these technologies to maintain competitive advantages and meet the high-quality standards that today’s markets demand. To stay at the forefront, incorporating reputable cylinder polishing machines into production lines is not just a luxury but a necessity in ensuring superior product quality and enhanced operational efficiency.