Custom Van Norman Centerless Grinders for Sale A Comprehensive Guide

When it comes to precision machining and metalworking, centerless grinding is a vital process that ensures components are finished to exact specifications. Among the various manufacturers that specialize in this technique, Van Norman stands out with its legacy of quality and innovation. Custom Van Norman centerless grinders offer unparalleled performance, allowing businesses to enhance their operations, reduce waste, and improve overall efficiency.

Understanding Centerless Grinding

Before diving into the specifics of Van Norman's machines, it’s essential to understand what centerless grinding is and why it is used. This method involves grinding two parallel surfaces simultaneously without the need for positioning the workpiece on a spindle. The process primarily consists of three components the grinding wheel, the regulating wheel, and the workpiece.

The workpiece is fed into the grinder in a specified orientation, resting between the two wheels. The grinding wheel removes material, while the regulating wheel controls the rotational speed and feed rate of the workpiece. This setup allows for extremely tight tolerances and a high degree of repeatability.

The Van Norman Advantage

Van Norman has a rich history in the machine tool industry and has been synonymous with quality and durability. Their centerless grinders boast several features that set them apart from competitors

1. Customization One of the key advantages of Van Norman grinders is their ability to be customized according to specific needs. Each machining task can vary dramatically, and having a machine that can be tailored to accommodate unique requirements can offer significant productivity benefits.

2. Robust Construction Van Norman grinders are designed with heavy-duty materials, ensuring longevity and reliability even when grinding tough materials. This robust construction translates into less maintenance time and lower operational costs over the machine's lifespan.

3. Precision Engineering The precision of Van Norman machines is highly regarded in the industry. They are capable of achieving tolerances that many other brands struggle to match. This is crucial for sectors like aerospace, automotive, and medical devices, where precision is non-negotiable.

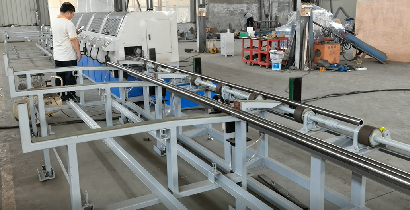

custom van norman centerless grinder for sale

4. User-Friendly Controls Even the most advanced machinery should be easy to operate. Van Norman's user interfaces are designed to be intuitive, reducing the learning curve for new operators and enabling faster setup and adjustment times.

Applications of Van Norman Centerless Grinders

Custom Van Norman centerless grinders can be used in a range of applications. These include but are not limited to

- Automotive Parts Manufacturing Cylindrical parts, such as shafts, bearings, and pins, require precise dimensions to fit into larger assemblies seamlessly. - Aerospace Components In this highly regulated industry, the slightest deviation in a part can lead to catastrophic failures. Thus, precision grinding is essential. - Medical Devices Manufacturing components with tight tolerances is critical in the medical field, where reliable functionality is paramount.

Finding Custom Van Norman Centerless Grinders for Sale

For businesses looking to invest in a custom Van Norman centerless grinder, several channels are available. Reputable machine tool dealers often have a wide selection of new and used machines. Many of these dealers offer tailored solutions and can assist you in acquiring a machine that best fits your specific needs.

Additionally, online marketplaces and industry-specific forums are excellent resources for finding both new and refurbished centerless grinders at competitive prices. When considering used machines, it’s wise to perform due diligence – inspecting the machine’s condition, asking about its operational history, and ensuring the seller offers some form of warranty or return policy.

Conclusion

A custom Van Norman centerless grinder can be an invaluable asset for any manufacturing operation that prioritizes precision and efficiency. With their robust construction, adaptability, and high-performance capabilities, these machines are built to tackle a variety of applications and deliver outstanding results. By investing in state-of-the-art grinding technology, businesses can improve their machining processes, set themselves apart in a competitive market, and ultimately achieve greater success. Whether you're looking to purchase new or used, exploring the options available on the market can help you make an informed decision that aligns with your operational goals.