Custom Tube Grinding Machines Tailoring Precision Manufacturing

In the rapidly evolving landscape of manufacturing, precision and customization are paramount to meeting the diverse needs of industries ranging from aerospace to automotive. One significant technological innovation that has emerged to address these demands is the custom tube grinding machine. Designed to enhance productivity and ensure exact specifications, these machines play a critical role in the fabrication of components that require impeccable surface finishes and precise dimensions.

Understanding Tube Grinding Machines

Tube grinding machines are specialized equipment used for finishing tube surfaces, achieving specific tolerances, and enhancing the mechanical properties of materials. They are engineered to grind various types of tubes, including stainless steel, aluminum, and other alloys, providing versatility across multiple sectors. The grinding process involves removing material from the outer or inner surfaces of a tube to achieve desired diameters, surface finishes, and improve overall quality.

The Importance of Customization

Custom tube grinding machines are particularly valuable because they can be tailored to meet the unique requirements of specific projects. Manufacturers often face unique challenges, such as tight tolerances, specialized materials, or unique geometries that standard machines cannot accommodate. Customization allows manufacturers to specify the precise features needed, including

1. Adaptable Grinding Heads The ability to easily change grinding heads or attachments to accommodate different tube sizes and materials enhances the flexibility of the machine.

2. Automated Features Incorporating automation in custom tube grinding machines improves efficiency. This includes automatic feeding systems, in-process measurements, and real-time adjustments to maintain consistency.

3. Enhanced Control Systems Advanced control systems enable operators to program the machine for a variety of tasks. This reduces human error and ensures repeatability, essential for mass production.

4. Tailored Cooling Systems Specific cooling methods can be designed to suit the material being processed, preventing overheating and maintaining the integrity of the metal during grinding.

Applications Across Industries

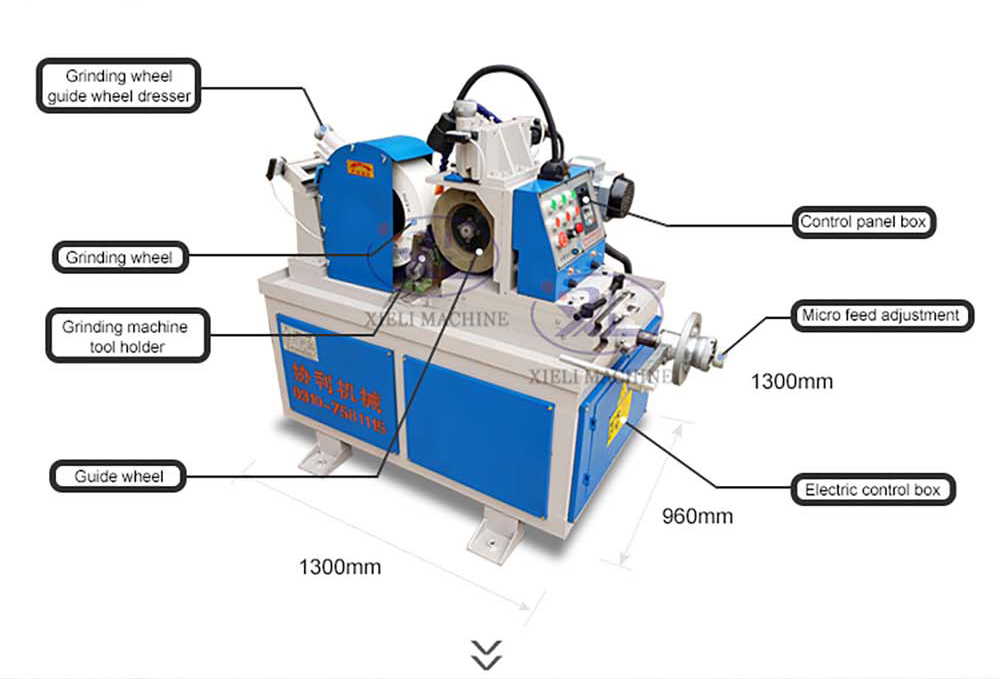

custom tube grinding machine

The applications of custom tube grinding machines are vast. In the aerospace industry, for instance, precision is critical. Components such as fuel lines, landing gear, and hydraulic tubes require exact dimensions and smooth finishes to function safely and efficiently. Similarly, in the automotive sector, custom grinding machines are used for producing exhaust systems, chassis components, and other vital parts where precision and durability are non-negotiable.

The medical industry, too, benefits greatly from custom tube grinding technologies. The fabrication of highly specialized instruments and implants demands rigorous standards and precise engineering. Custom tube grinding machines ensure that medical devices meet stringent regulatory requirements while also achieving the required performance characteristics.

Benefits of Investing in Custom Machines

Investing in custom tube grinding machines can yield significant advantages for manufacturers. These benefits include

- Increased Efficiency Custom machines optimized for specific tasks inherently increase production rates and reduce downtime.

- Improved Quality The ability to meet stringent specifications minimizes rework and scrap rates, contributing to higher overall product quality.

- Cost-Effectiveness Though initial investments may be higher, the long-term savings from reduced labor, improved efficiency, and minimized waste can offset these costs significantly.

- Competitive Edge Companies that can offer customized products with quicker turnaround times gain a distinct advantage over competitors.

Conclusion

In a world where precision manufacturing is essential, custom tube grinding machines stand out as pivotal tools that enable manufacturers to meet the specific demands of their industries. By embracing innovation and customization, companies can improve product quality, enhance efficiency, and secure their place in the competitive market landscape. As technology continues to advance, the role of these specialized machines will undoubtedly become even more critical in shaping the future of various sectors, reflecting the endless possibilities of modern engineering and manufacturing.