Custom Pipe Polishing Machines for Sale The Ideal Solution for Your Manufacturing Needs

In today's manufacturing landscape, maintaining the quality and aesthetic appeal of finished products is paramount. One of the crucial steps in the production process is ensuring that stainless steel pipes and other metal components have a smooth, polished finish. This is where custom pipe polishing machines play a vital role. These machines are designed to meet specific manufacturing needs and enhance the overall appearance and durability of pipes, making them essential for various industries.

The Importance of Pipe Polishing

Pipe polishing is not merely a cosmetic enhancement. A polished surface can significantly improve the corrosion resistance of metal, ensuring longer product life. Additionally, polished pipes are more hygienic, which is essential in industries such as food processing, pharmaceuticals, and biotechnology. The smooth finish prevents the accumulation of bacteria and other contaminants, ensuring that products meet strict health and safety regulations.

Types of Custom Pipe Polishing Machines

There are several types of pipe polishing machines available in the market, each designed for specific applications and requirements. Here are a few common types

1. Manual Pipe Polishers These machines are suitable for small-scale operations or workshops where flexibility and customization are required. Operators can adjust the polishing steps to meet the desired finish, although this method is labor-intensive and may not be as efficient for large volumes.

2. Automatic Pipe Polishing Machines Designed for high-volume production, automatic polishers significantly reduce labor costs and improve efficiency. These machines often come with advanced features such as programmable settings, allowing manufacturers to produce consistent finishes with minimal human intervention.

3. CNC Pipe Polishers Computer Numerical Control (CNC) machines offer precision and versatility. They can be programmed to polish pipes of various sizes and shapes, ensuring a perfect finish every time. CNC machines are ideal for manufacturers that require high precision and repeatability in their operations.

4. Multi-head Polishers These machines are designed to polish multiple pipes simultaneously, making them highly efficient for large-scale manufacturing. The use of multiple polishing heads allows for uniform polishing across all surfaces, saving time and reducing labor costs.

Customization Options

custom pipe polishing machine for sale

When it comes to manufacturing equipment, one size does not fit all. Custom pipe polishing machines offer various customization options to meet specific manufacturer needs. From the size and capacity of the machine to the polishing heads and abrasives used, customization allows businesses to optimize their production processes.

Some manufacturers may require additional features such as dust collection systems, variable speed controls, and specific polishing techniques like belt, brush, or wheel polishing. Discussing customization options with machine suppliers can lead to tailored solutions that enhance productivity and product quality.

Choosing the Right Supplier

Selecting the right custom pipe polishing machine supplier is crucial to ensure you receive a high-quality product that meets your production needs. Here are some key factors to consider when choosing a supplier

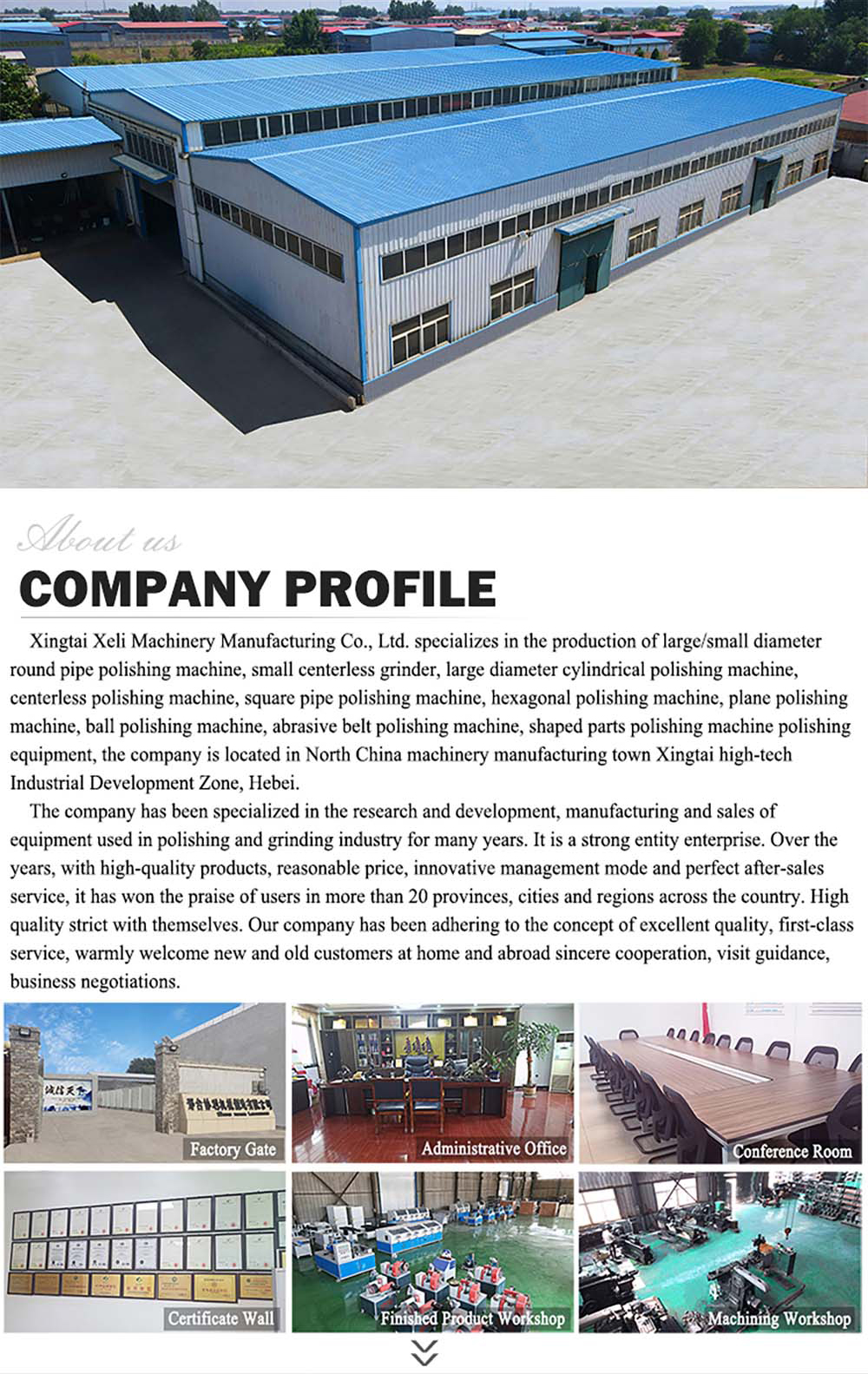

- Reputation and Experience Look for a supplier with a solid reputation in the industry. Experienced suppliers will have a track record of providing reliable and effective polishing solutions.

- Technical Support A good supplier should offer excellent technical support and after-sales service. This is essential for troubleshooting issues and ensuring that your machine operates smoothly.

- Customer Testimonials Customer feedback and testimonials can provide valuable insights into the performance and reliability of the machines offered by the supplier.

- Warranty and Maintenance Ensure that the supplier provides a comprehensive warranty and maintenance options for their machines. This will help you mitigate any potential downtime and repair costs in the future.

Conclusion

In conclusion, custom pipe polishing machines are an indispensable investment for manufacturers looking to enhance the quality and longevity of their products. By understanding the different types of polishing machines, customization options, and selecting the right supplier, businesses can improve their production processes and uphold high standards in product finish and durability. Investing in quality polishing equipment is not just about enhancing aesthetics; it’s about ensuring safety, compliance, and satisfaction in an increasingly competitive market.