Customized CNC Centerless Grinder Suppliers Elevating Precision in Manufacturing

In the realm of precision machining, the demand for high-quality, reliable equipment has never been higher. One essential tool at the forefront of this manufacturing revolution is the CNC centerless grinder. These machines offer unparalleled precision and efficiency for grinding various materials. As industries seek specialized solutions tailored to their unique needs, the emergence of customized CNC centerless grinder suppliers has become critical in meeting these demands.

Understanding CNC Centerless Grinders

CNC (Computer Numerical Control) centerless grinders are designed for high-volume production of components. Unlike traditional grinders, centerless grinders do not require the workpiece to be mounted between centers. Instead, the workpiece is held in place by the grinding wheel and the regulating wheel, allowing for continuous and automated grinding operations. This design not only enhances speed but also improves the accuracy of the finished product.

The popularity of CNC centerless grinders stems from their ability to handle a wide range of materials and sizes, making them indispensable in sectors such as automotive, aerospace, and medical device manufacturing. The capacity for automation and integration into lean manufacturing processes further solidifies their status as a game-changer in machining.

The Importance of Customization

While standard CNC centerless grinders serve many applications effectively, there are instances where bespoke solutions are necessary to achieve optimal results. Customized CNC centerless grinder suppliers play a pivotal role in providing machines that meet specific requirements, including

1. Precision Specifications Different industries have varying tolerances and specifications for dimensional accuracy. Customized grinders can be designed to meet these exacting standards, ensuring that components are produced with high precision.

2. Material Compatibility Not all machines are suitable for every material. Custom suppliers can develop grinders that accommodate unique materials, whether it be hardened steel, non-ferrous metals, or even plastics.

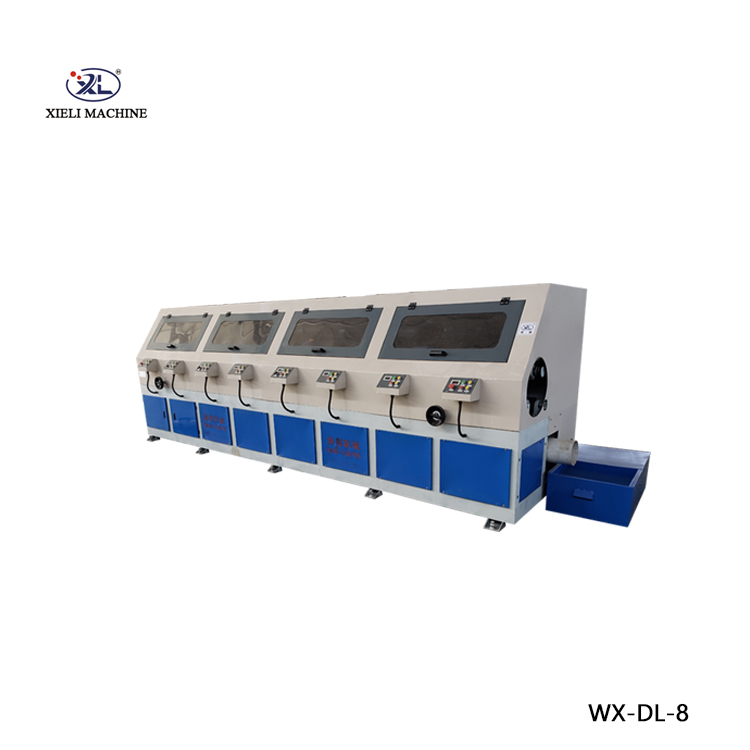

customized cnc centerless grinder suppliers

4. Integration with Existing Systems Custom centerless grinders can be designed to seamlessly integrate into existing manufacturing processes, facilitating smoother workflows and reducing downtime.

5. User-Friendly Features Custom suppliers often focus on the end-user experience, incorporating features that enhance usability, such as intuitive controls, enhanced safety measures, and simplified maintenance protocols.

Choosing the Right Supplier

When exploring the market for customized CNC centerless grinders, manufacturers should consider several factors to ensure they partner with the right supplier

- Expertise and Experience Suppliers with a proven track record in designing and delivering customized grinding solutions will likely have the necessary knowledge to address specific challenges effectively.

- Technological Capabilities Advanced suppliers utilize cutting-edge technology and innovative designs to enhance machine performance. Look for those who invest in research and development to stay ahead of industry trends.

- Customer Support and Service A reliable supplier should offer robust customer support, including training, maintenance services, and technical assistance. A strong post-sale relationship is vital for long-term success.

- Client Testimonials and Case Studies Analyzing feedback from previous clients can provide insights into a supplier’s reliability, product performance, and overall satisfaction.

Conclusion

The evolution of manufacturing processes demands precision, efficiency, and customization, and CNC centerless grinders are vital players in this landscape. Customized CNC centerless grinder suppliers are uniquely positioned to meet the distinct needs of various industries, helping manufacturers achieve higher productivity and superior product quality. By choosing the right supplier, businesses can leverage advanced grinding technology to drive success in an increasingly competitive market. As manufacturing continues to evolve, the role of these specialized suppliers will undoubtedly become more significant, paving the way for innovations that enhance both efficiency and precision in various production environments.