Customized CNC Centerless Grinder Supplier Revolutionizing Precision Manufacturing

In the competitive landscape of modern manufacturing, precision, efficiency, and quality are paramount. One of the key machinery players in achieving these objectives is the centerless grinder. A customized CNC centerless grinder is essential for manufacturers who require highly precise grinding processes tailored to their unique production needs. This article will explore the significance of customized CNC centerless grinder suppliers and how they are transforming the industry.

The Importance of Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece without the need for a fixed location. This technique allows for high-speed production of cylindrical parts, ensuring excellent surface finishes and tight tolerances. Industries such as automotive, aerospace, medical device manufacturing, and many others rely heavily on centerless grinding to create components that meet stringent specifications.

Tailored Solutions for Diverse Applications

Every manufacturing operation is distinct, with specific requirements concerning production volume, part geometry, material type, and desired finish. This is where the role of customized CNC centerless grinder suppliers comes into play. By offering tailored solutions, these suppliers ensure that the grinding machines are optimized for the unique demands of their clients.

Customized grinders can be designed to handle various sizes and shapes of workpieces, from small precision components to larger industrial parts. Features such as adjustable grinding wheel configurations, enhanced cooling systems, and advanced automation capabilities can significantly increase productivity and efficiency.

Enhancing Production Efficiency and Quality

One of the primary advantages of utilizing a customized CNC centerless grinder is its ability to enhance production efficiency. Traditional grinding methods often involve multiple setups and lengthy changeover times, which can lead to increased downtime and reduced output. A well-designed centerless grinder can perform multiple tasks simultaneously, greatly reducing the time needed for production runs.

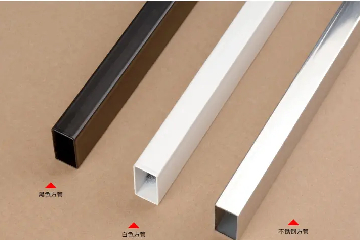

customized cnc centerless grinder supplier

Furthermore, consistency and quality are vital in manufacturing. Customized CNC centerless grinders incorporate advanced technology, such as CNC controls and high-precision measuring systems, which enable real-time monitoring and adjustments. This automation minimizes human error, ensures repeatability, and guarantees that every part produced meets the required specifications.

The Role of Advanced Technology in Customization

The advent of Industry 4.0 has ushered in a new era of manufacturing, characterized by smart factories and interconnected systems. Customized CNC centerless grinder suppliers are leveraging advanced technologies such as artificial intelligence (AI), machine learning, and IoT (Internet of Things) to enhance their offerings.

By integrating smart sensors and data analytics into their grinding machines, suppliers allow manufacturers to monitor performance metrics in real-time. This data-driven approach facilitates predictive maintenance, reducing the risk of machine failures and optimizing overall performance.

Partnering with the Right Supplier

Choosing the right customized CNC centerless grinder supplier is pivotal for manufacturers aiming to enhance their production capabilities. Factors to consider include the supplier's experience, the range of customization options available, support services offered, and their reputation in the industry.

A reliable supplier will work closely with clients to understand their specific needs and provide solutions that align with their manufacturing goals. Additionally, ongoing support and training are crucial for ensuring that operators are well-versed in utilizing the machinery effectively.

Conclusion

In conclusion, the demand for customized CNC centerless grinders is steadily increasing as manufacturers strive for precision, efficiency, and quality in their production processes. By partnering with a knowledgeable and experienced supplier, businesses can access cutting-edge technology that meets their specific requirements. As the landscape of manufacturing continues to evolve, customized CNC centerless grinders will remain an invaluable asset in the relentless pursuit of excellence in production.