Customized Centerless Grinder Supplier Enhancing Precision Machining

In the world of precision machining, the need for highly accurate and reliable machinery cannot be overstated. One of the key players in this realm is the centerless grinder, an essential tool for achieving high precision in various industries, including automotive, aerospace, and manufacturing. As a result, the demand for customized centerless grinder suppliers has surged, as companies look for tailored solutions to enhance their production processes.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from the surface of an object, allowing for the production of highly precise cylindrical shapes. Unlike traditional grinding processes, where the workpiece is held between two centers, centerless grinding allows the workpiece to be supported by a combination of a grinding wheel, a regulating wheel, and a work rest. This unique setup enables continuous feeding of the workpiece, ultimately leading to increased efficiency and reduced production times.

The Importance of Customization

Every industry has its unique requirements and challenges. Therefore, a one-size-fits-all approach rarely delivers optimal results. Customized centerless grinders provide solutions tailored to specific needs, allowing manufacturers to achieve better precision, efficiency, and adaptability in their operations. For instance, different materials require different grinding techniques and wheel specifications. A customized supplier can provide grinding solutions that enhance the performance of particular materials, whether they are metals, plastics, or composites.

Key Features of Customized Centerless Grinders

1. Versatile Design Customized centerless grinders can be designed to accommodate various sizes, shapes, and materials. This versatility ensures that manufacturers can use the machinery for a wide range of applications within their production lines.

2. Enhanced Precision Tailored solutions often include advanced technology and features that enhance the precision of the grinding process. This can include more accurate wheel alignment, better feed control, and improved vibration dampening mechanisms.

3. User-Friendly Operation A focus on ergonomic design can make customized grinders easier to operate. This includes accessible controls, safety features, and intuitive interfaces that enhance usability for machine operators.

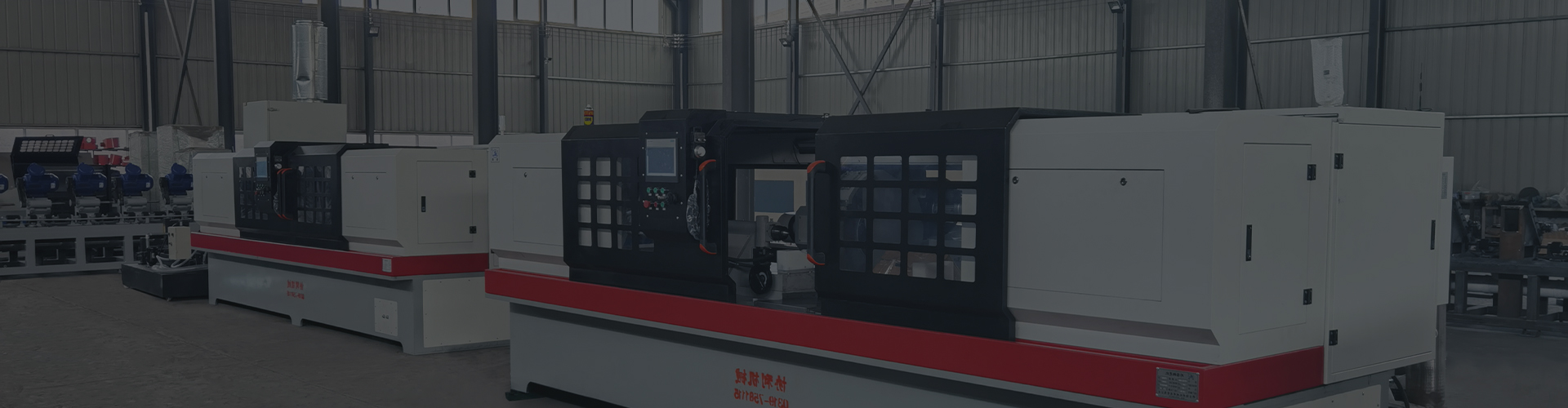

customized centerless grinder supplier

4. Integration with Automation Modern manufacturing often involves automation for efficiency. Customized centerless grinders can be integrated into automated production lines, enabling seamless operation and further enhancing productivity.

5. Flexible Adaptability As market demands change, so too do production needs. Customized grinders can be designed with modular components that allow for easy upgrades or modifications, ensuring the equipment remains relevant and useful over time.

Choosing the Right Supplier

When it comes to selecting a customized centerless grinder supplier, several factors should be considered

- Experience and Expertise Look for suppliers with a proven track record and deep understanding of the machining industry. Their experience can provide valuable insights into the best solutions for specific needs.

- Technological Innovation A supplier should be committed to innovation and use the latest technologies in their grinder designs. This commitment can greatly influence the performance and longevity of the equipment.

- Comprehensive Support Beyond the initial sale, a reliable supplier will offer ongoing support, including installation, training, and maintenance services. This ensures that the equipment is properly utilized and stays in peak condition.

- Customization Capabilities Assess the supplier’s ability to tailor solutions specific to your business requirements. The more adaptable they are in their design and manufacturing processes, the better they are equipped to meet unique challenges.

Conclusion

In summary, the role of customized centerless grinder suppliers is crucial in the landscape of precision machining. By providing tailored solutions, these suppliers not only meet the diverse needs of various industries but also encourage innovation and efficiency within production processes. As businesses continue to seek ways to improve their manufacturing capabilities, investing in customized centerless grinders can provide the precision and reliability needed to stay competitive in a fast-paced market. Choosing the right supplier is a key step in this journey, as their expertise and commitment to innovation directly influence the quality of the grinding solutions offered.