In the realm of precision engineering, the significance of centerless grinding cannot be overstated. Particularly for those seeking customized solutions, the choice of a suitable manufacturer hinges on understanding not just the technical specifications, but the nuanced expertise and authoritative practices that define top-tier suppliers.

Centerless grinders are pivotal in achieving high-precision surface finishes and dimensional accuracy, critical criteria in industries ranging from aerospace to automotive engineering. Unlike traditional grinding methods that rely on centers to hold the workpiece, centerless grinding operates with the part supported between a grinding wheel and a regulating wheel. This system excels in handling high volumes while maintaining exacting standards of precision.

The allure of customized centerless grinders lies in their ability to offer solutions tailored to specific industry requirements. Manufacturers that specialize in customization don't just produce equipment; they engineer solutions that seamlessly integrate into existing production lines, enhancing efficiency and output. Expert manufacturers often provide bespoke modifications such as varying grinding diameters, automation compatibility, and material-specific adaptability—allowing clients to maintain a competitive edge in their production capabilities.

Expertise is the linchpin of any capable centerless grinder manufacturer. These manufacturers usually have a cadre of engineers with extensive backgrounds in materials science, mechanical engineering, and computer-aided design. Through the confluence of these disciplines, they craft grinders that not only meet but exceed client expectations. This expertise ensures that machinery is robust, efficient, and capable of handling the unique material properties of various industry-specific sectors, whether dealing with hardened steel or advanced composites.

The authority of a manufacturer often reflects in their certifications and industry affiliations. Top-of-the-line manufacturers maintain ISO certifications, ensuring that their production processes adhere strictly to international standards of quality. Further, affiliations with industry bodies like the Grinding and Abrasive Machining Society promote ongoing development through workshops, seminars, and technology updates, reinforcing their position as industry leaders.

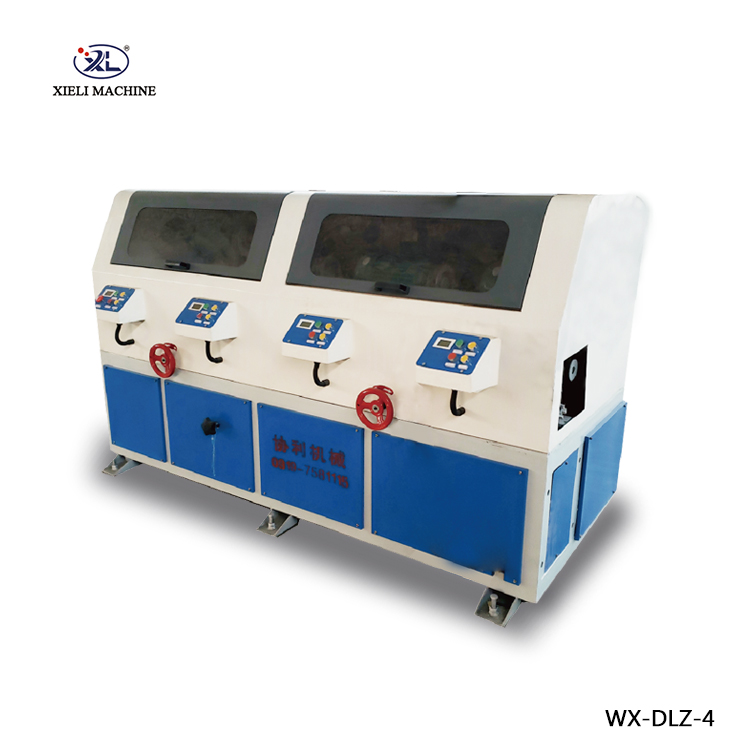

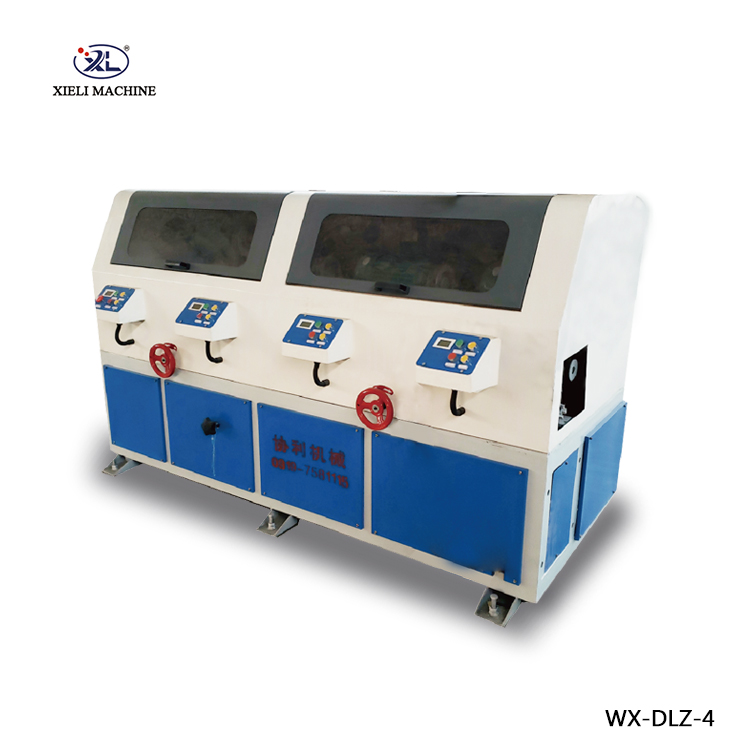

customized centerless grinder manufacturers

In the quest for trusted partnerships, the credibility of a manufacturer is paramount. Testimonials and case studies are invaluable in establishing trustworthiness. Prospective clients should delve into available reviews, seeking examples of past collaborations that underscore reliability and consistency. A trustworthy manufacturer is transparent in their dealings, with clear timelines, upfront cost estimates, and definitive post-installation support policies. This transparency breeds confidence, reassuring clients of sustained product performance and prompt resolutions in the event of technical challenges.

Moreover, the rapid evolution of digital technology in manufacturing means that contemporary centerless grinder manufacturers are embracing Industry 4.0 principles. This encompasses integrating IoT-enabled diagnostics and predictive maintenance systems into their products to preemptively identify potential disruptions, thereby minimizing downtime. Such advanced capabilities not only bolster operational efficiencies but also demonstrate a manufacturer's commitment to cutting-edge innovation.

Those exploring custom solutions should also consider a manufacturer's dedication to environmental sustainability. Companies that prioritize eco-friendly practices—such as implementing energy-efficient components and waste-reducing techniques—position themselves favorably in a market increasingly driven by ecological consciousness.

For decision-makers seeking to capitalize on the competitive advantages of customized centerless grinders, aligning with a manufacturer that embodies experience, expertise, authoritativeness, and trustworthiness is essential. Engaging with such a manufacturer guarantees a solution that not only fulfills current operational needs but is adaptable to future advancements, ensuring continued excellence in production outcomes.

The intersection of quality craftsmanship, tailored solutions, and trusted partnerships defines the landscape of customized centerless grinder manufacturers—a landscape where only those committed to the highest echelons of precision and innovation will not just survive, but thrive.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.